Dosing solids

Feeding powders

Sobatech dedicated years of efforts in bringing the most advanced and accurate continuous dosing hardware and software to market. This resulted in the flat bottom dosing hopper design that prevents flow through feeder challenges like arching and bridge building. Also, it prevents compressibility of the powders as a result of the increased headload after refilling. Sobatech’s gravimetric feeders ensure extreme high accuracies during both loss-in-weight as well as gain-in-weight operation.

Sobatech only works with gravimetric feeders which constantly measure the weight reduction per time unit. The weight is measured by using (digital) load cells; the foundation of the entire feeding system. The motor automatically alters its speed when a change is detected in the material flow. By running feeders in gravimetric mode, possible underlying variations in bulk density or screw flight loading are automatically corrected for and an extreme high dosing accuracy is achieved.

Sobatech developed its own tailor made open source software to control its feeders and other hardware involved in the continuous dosing of the ingredients. In Sobatech’s feeding technology there are no hidden programs nor protected passwords. The complete system is open and accessible to the customer.

Product specification

Sobatech offers two different dosing systems for gravimetrically dosing the powder ingredients: (1) The gravimetric weighing belt and/or (2) The gravimetric weighing hopper.

1. THE WEIGHING BELT

A weighing belt operates by continuously weighing a moving bed of material on a short conveyor belt and controlling that belt speed to result in the desired flow rate at discharge.

CAPACITY

Unlike most loss in weight feeding systems whose physical size must typically be increased to accommodate higher flow rates, weight belt feeders can achieve high rates while remaining compact. The system is flexible in regards to the quantities it can dose; it can feed between 20 and 10.000 kg of powder per hour.

GAIN-IN-WEIGHT (REFILL)

As a weighing belt is not measuring loss-in-weight, there can be an open connection between the receiving hopper and the weighing belt system. This prevents challenges of compressibility as a result of the increased head-load after refilling a loss-in-weight feeder.

MOUNTING FRAMES

The gravimetric weighing belt is mounted on a stable U-frame that is by means of shock mounts connected to the platform. The weighing belt is by means of flexible hoses connected to the homogenizer (phase 1 mixing). In the homogenizer the powders are injected by the liquid ingredients and thereafter enter the actual continuous mixer (phase 2 mixing).

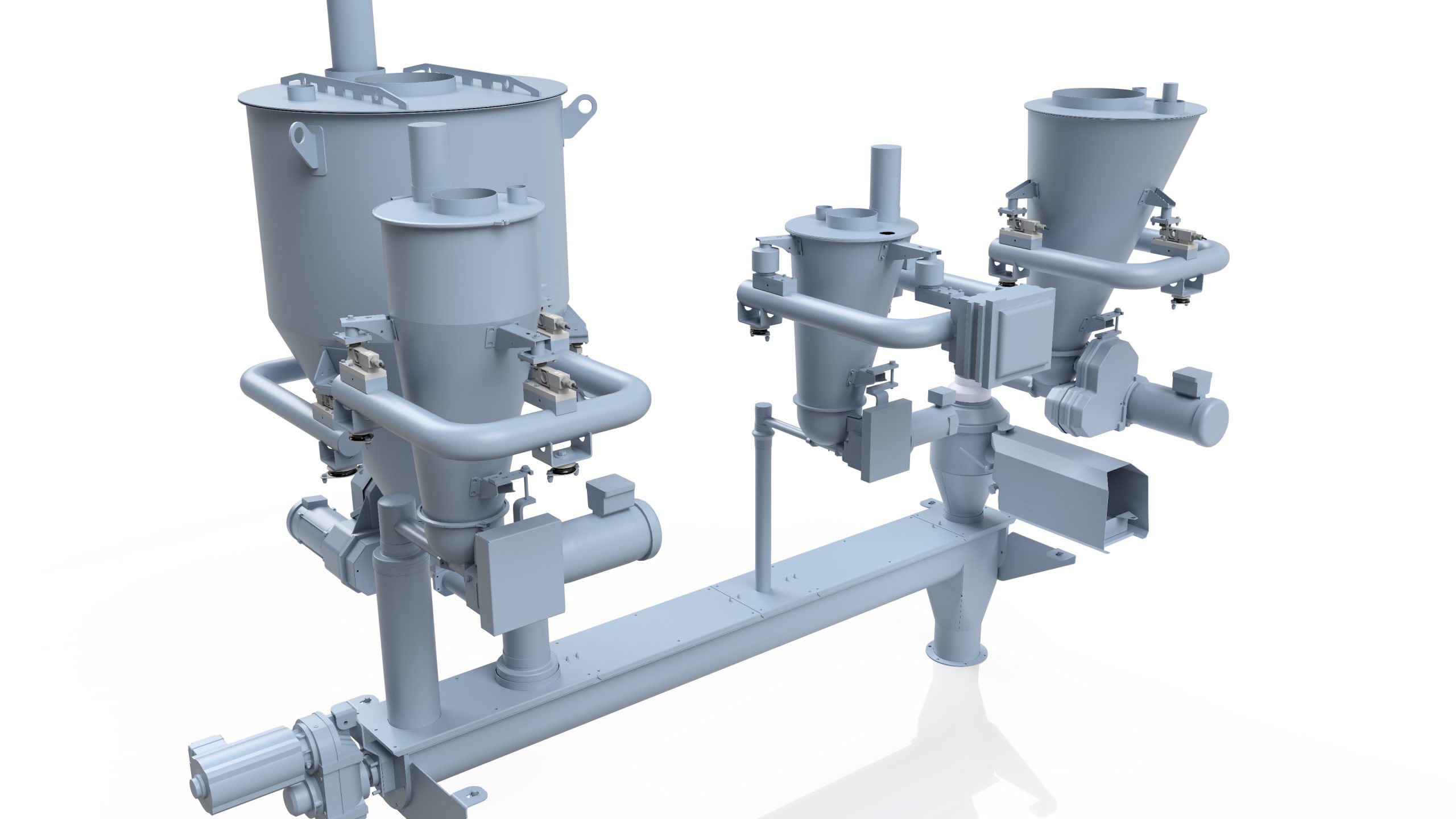

2. THE WEIGHING HOPPER

The well-known gravimetric dosing hoppers are located on loadcells that constantly measure the weight reduction per time unit.

CAPACITY

The gravimetric weighing hoppers are offered in a variety of different sizes and designs. Please contact one of our team members to learn which design fits your process best.

GAIN-IN-WEIGHT (REFILL)

Sobatech latest dosing hopper design is called: ‘the flat botttom dosing hopper’ and has significant advantages in relation to the gain in weight (refilling) process. As the location of the dosing screws is different from the location of refilling – compressibility of powders, as a result of an increased headload, is minimized. This allows for an accurate dosing result in both loss-in-weight as well as gain-in-weight operation.

MOUNTING FRAMES

The gravimetric dosing hopper is mounted on a stable U-frame that is by means of shock mounts connected to the platform. The outlet of the hopper is by means of flexible hoses connected to the homogenizer (phase 1 mixing). The powders fall through the homogenizer into the actual continuous mixer.