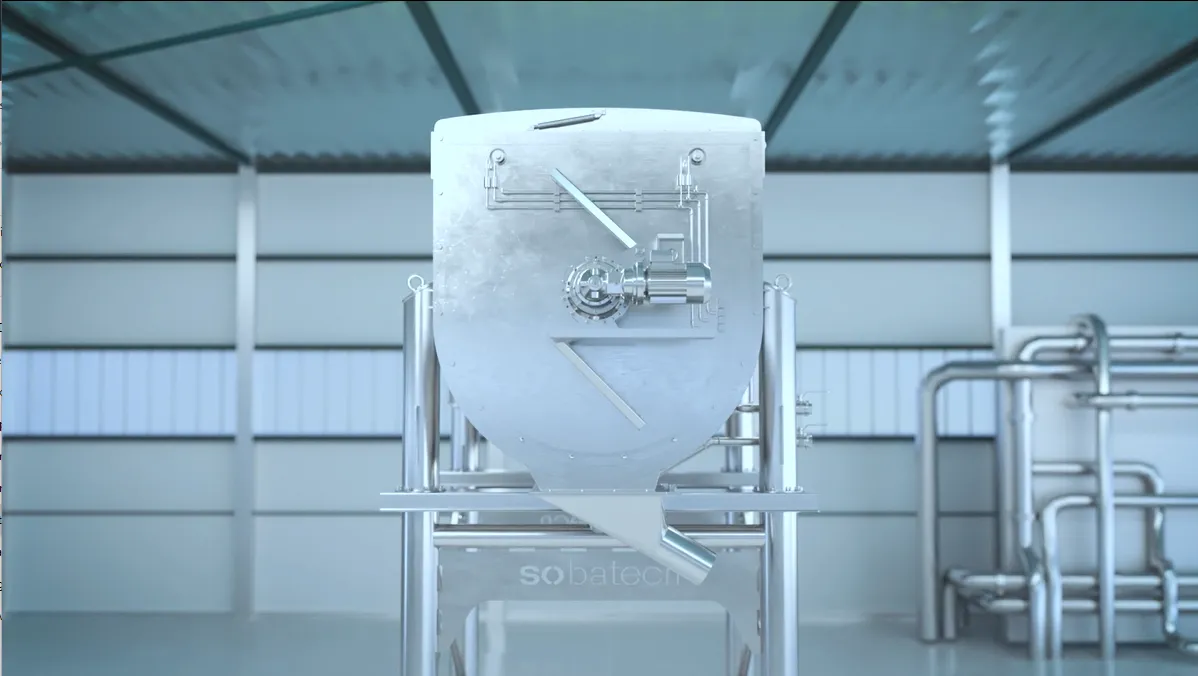

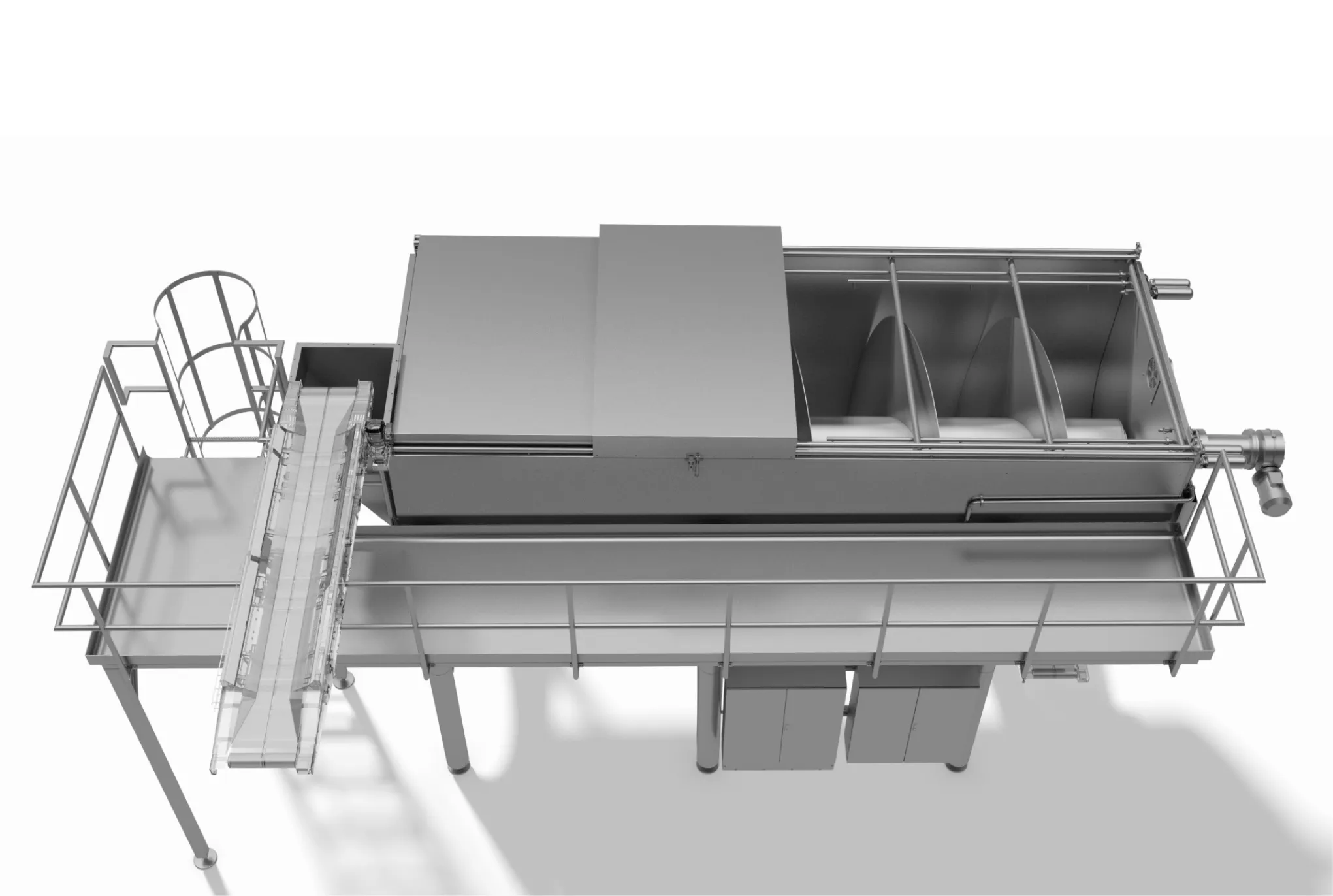

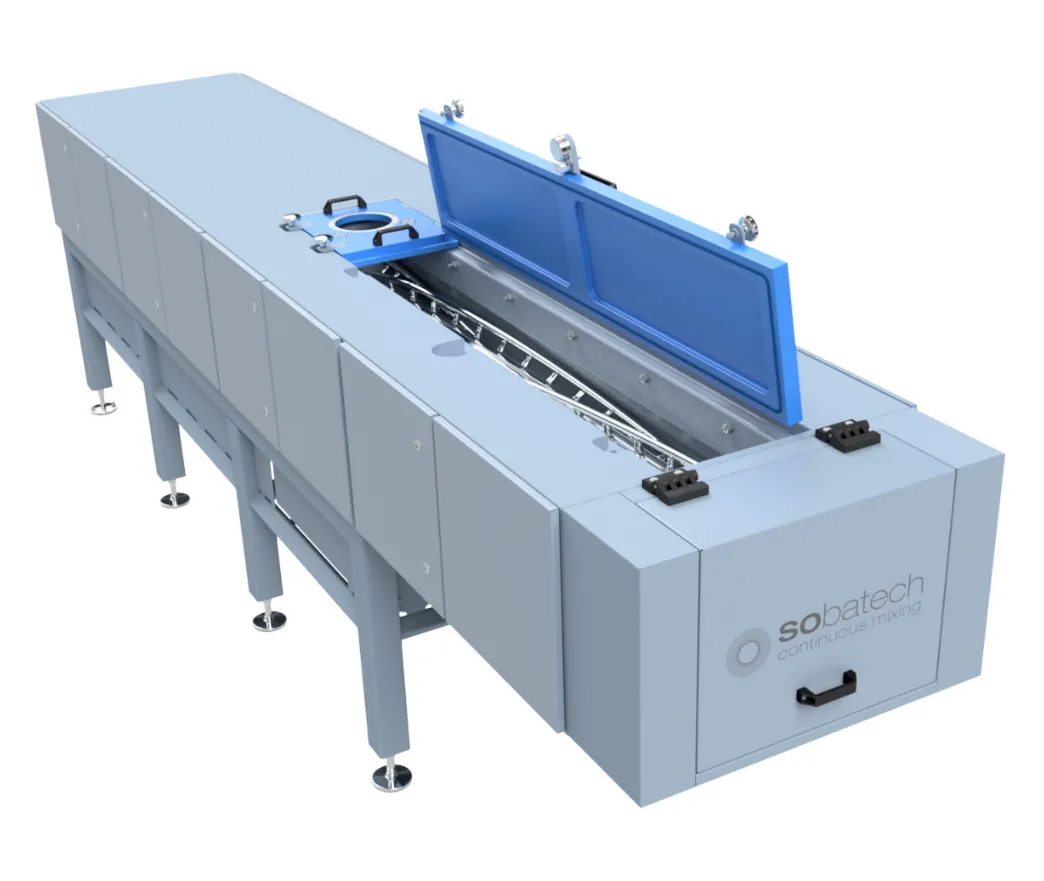

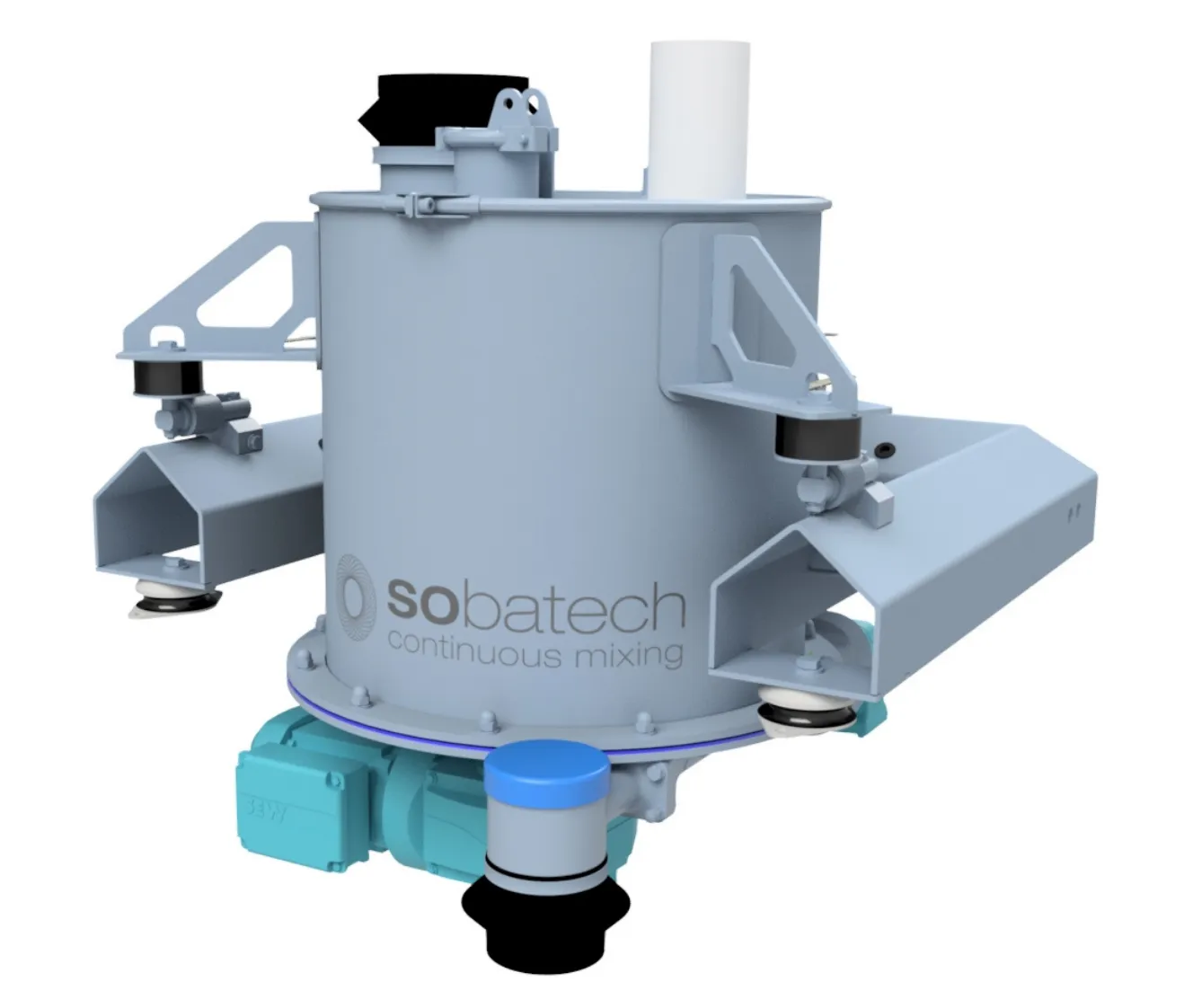

Sobatech offers continuous bulk fermenters that can be placed directly after the continuous mixing systems. At the outlet of the continuous mixer, there is a vertical belt to bring the product into the fermenter tube. The fermentation time can be controlled by adjusting the screw speed in that tube. The set point of the speed is included in the final recipe. At the outlet of the fermenter, there is a divider that takes out the product in a controlled and gentle way.

The continuous fermenter has double jackets to stabilize the product temperature. It is also possible to control humidity inside the tube. Combining time with an equal and controlled exposure to the right environmental conditions are the vital features of a Sobatech continuous bulk fermenter. Sobatech’s system control software allows to easily monitor and modify the temperature, humidity and speed of the continuous fermenter.

.webp)

%20hydrator.webp)

.webp)