So

efficient

Our Products...

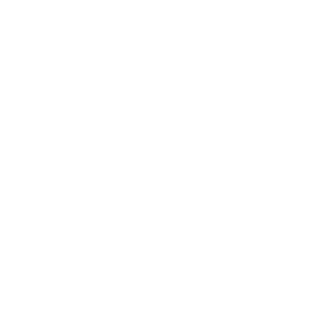

Continuous (TVP) hydrater

Between 2018 and 2020, the meat substitutes market revenue has increased by more than 83%. Meat replacers characterised by being indistinguisable from real meat mostly consist of Texturized Vegetable Proteins (TVP). In order to offer a complete automated and continuous ... read more >

Dosing liquids

Correct weighing of ingredients is essential for reaching the required product quality. If the various raw materials are not dispensed in the correct quantities to begin with, it will never be possible to produce a correct product. Therefore, Sobatech dedicated ... read more >

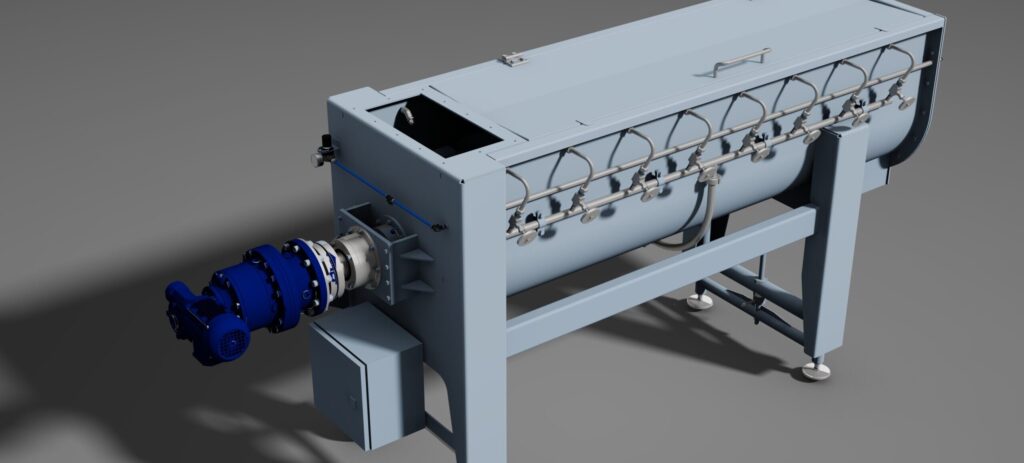

Dosing solids

Sobatech dedicated years of efforts in bringing the most advanced and accurate continuous dosing hardware and software to market. This resulted in the flat bottom dosing hopper design that prevents flow through feeder challenges like arching and bridge building. Also, ... read more >

Vacuum mixer

Vacuum mixing is a process used in various industries, including pharmaceuticals, food, and cosmetics, to mix and homogenize ingredients under vacuum conditions. Sobatech’s vacuum process involves a continuous degassing system creating a low-pressure environment by removing air from the mixing ... read more >

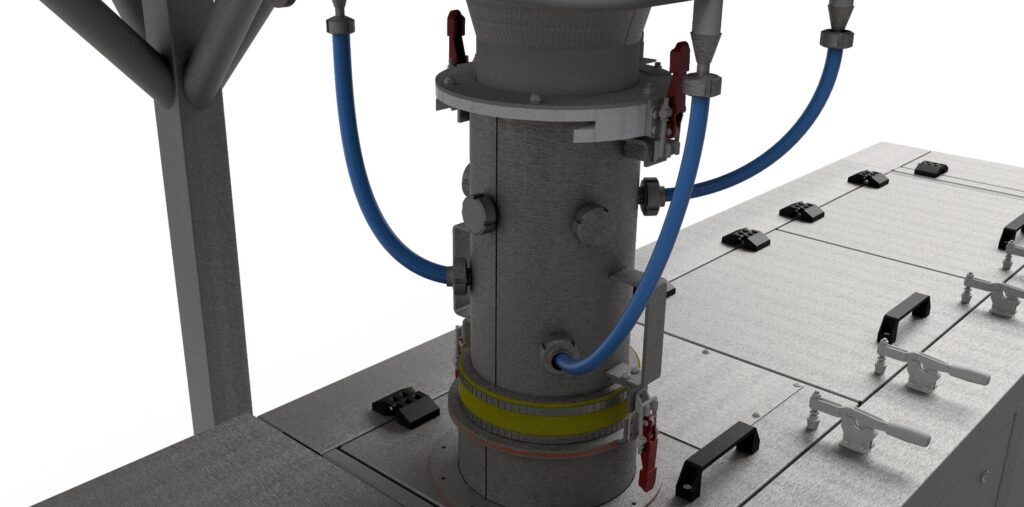

The homogenizer

The homogenizer is a tube shaped device responsible for injecting the liquid ingredients, by means of medium pressure, into the powder ingredients like flour and premix. Sobatech’s continuous mixing system consists out of a 2-phase process for mixing the ingredients ... read more >

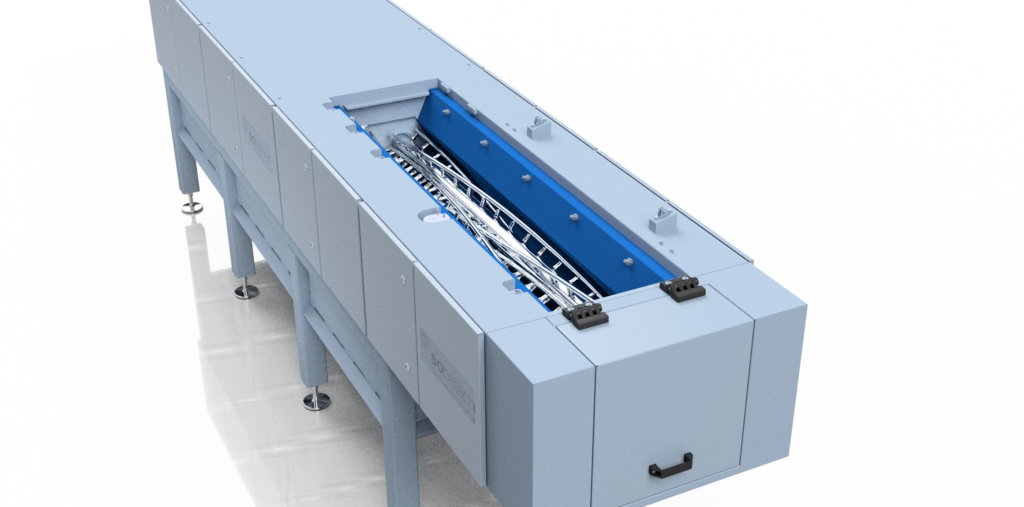

The continuous mixer

The Sobatech continuous mixing system consist out of two mixing phases. First of all, the ingredients are evenly and accurately distributed over the complete mass (phase 1 mixing). After that, controlled mechanical energy is applied to the blend of ingredients ... read more >

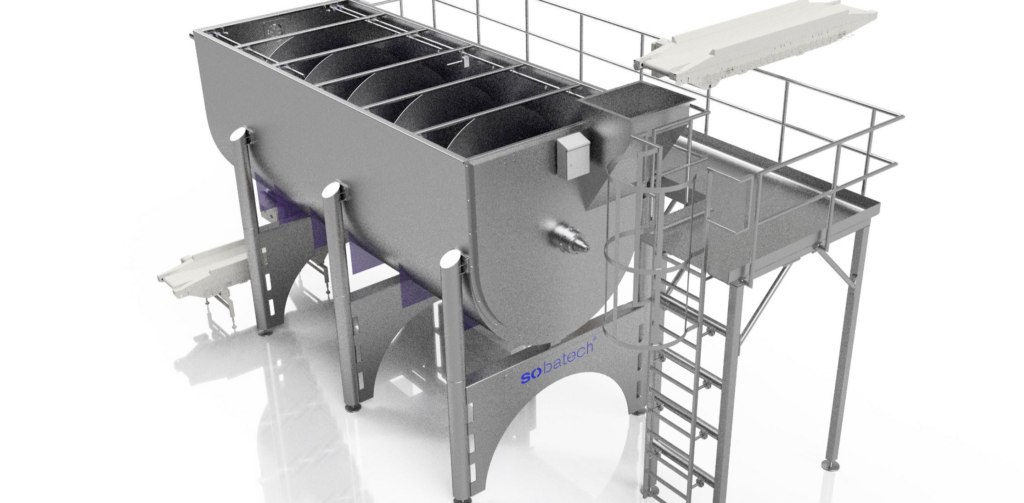

Continuous bulk fermentation

Sobatech’s continuous bulk fermenters allow products to rest under controlled environmental conditions. Ensuring each part of the product is exposed to the same environmental conditions is essential for reaching the desired end-product quality and consistency. Sobatech offers continuous bulk fermenters that ... read more >YOUR PRODUCTS..

Todays manufacturers master recipes that are more and more elaborate and varied. At the same time, the quality of the product must be consistent in order to repeat recipes identically on a large scale and increase yield. It is an Industrial dough mixer’s task to reduce labor, cut costs and improve quality consistency. Check out a few of our proven applications below.

Our Process..

CONTINUOUS DOSING INGREDIENTS

Correct weighing of ingredients is essential for reaching the required product quality. If the various ingredients are not dosed in the correct quantities to begin with, it will never be possible to produce a correct product. For that reason, Sobatech ...

Find out more

CONTINUOUS DOUGH MIXING

A Sobatech continuous mixing system uses a two phase process for mixing ingredients into a consistent and homogeneous mass. First, all ingredients are evenly and accurately distributed over the complete mass (phase 1 mixing: the homogenizer). Then, the development takes ...

Find out more

CONTINUOUS BULK FERMENTATION

The Sobatech continuous bulk fermentation process allows the dough to rest for the development of taste, consistency and aroma. Time is a key factor within this continuous bulk fermentation process. Besides time, also ensuring each part of the mass is ...

Find out more