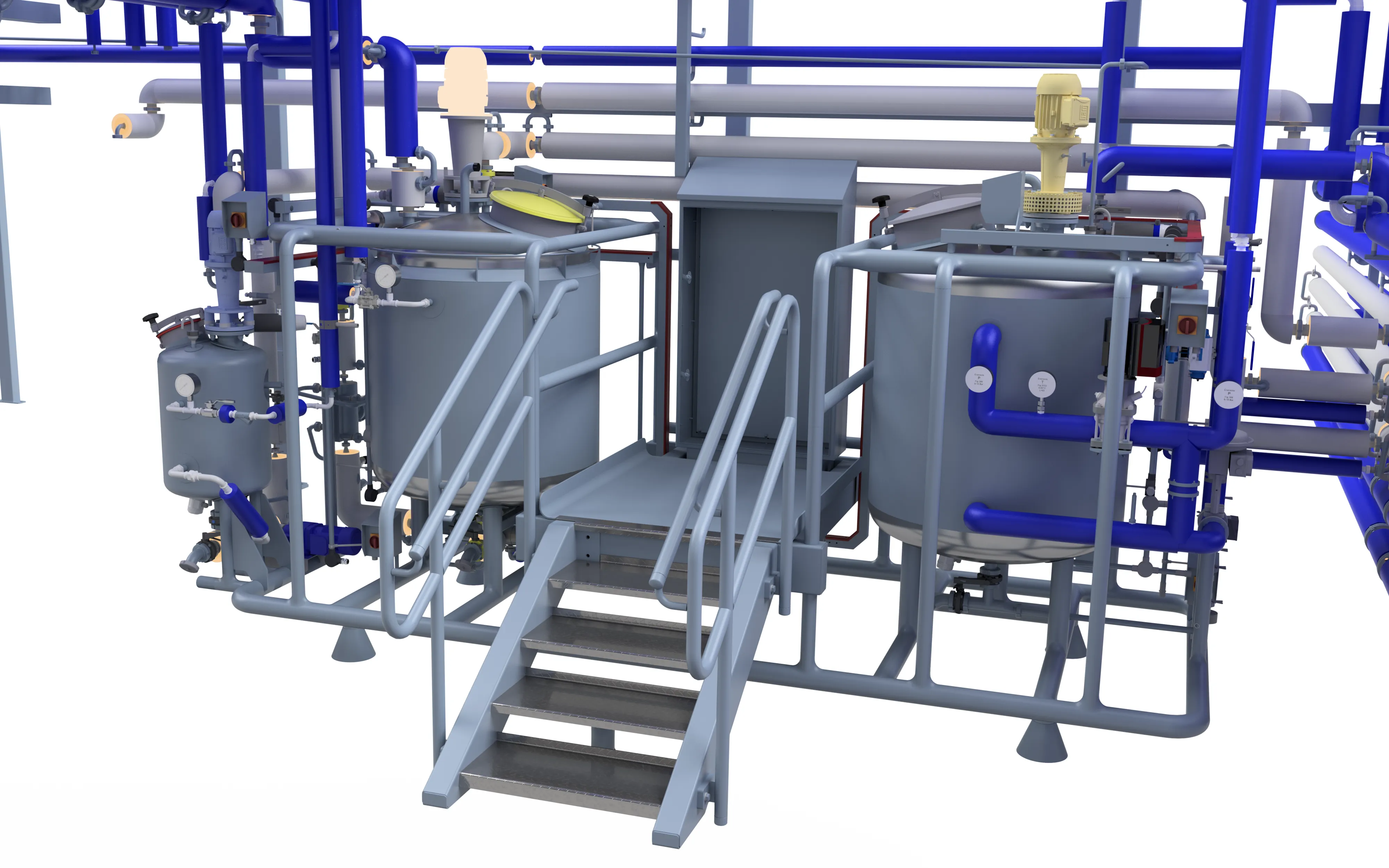

Liquids are tapped from an existing IBC, storage tank, or circulation pipeline and transferred using a positive displacement pump. The tanks can be equipped with level sensors that send signals to the PLC when refilling is required. The volume of the buffer tank is determined by the desired hourly throughput.To maintain optimal temperature control, the holding tanks can be fitted with double jackets. Similarly, both the pump and flow sensor can be jacketed to prevent product solidification. A vertical agitator is employed to ensure homogeneous blending and consistent mixing of liquid premixes.

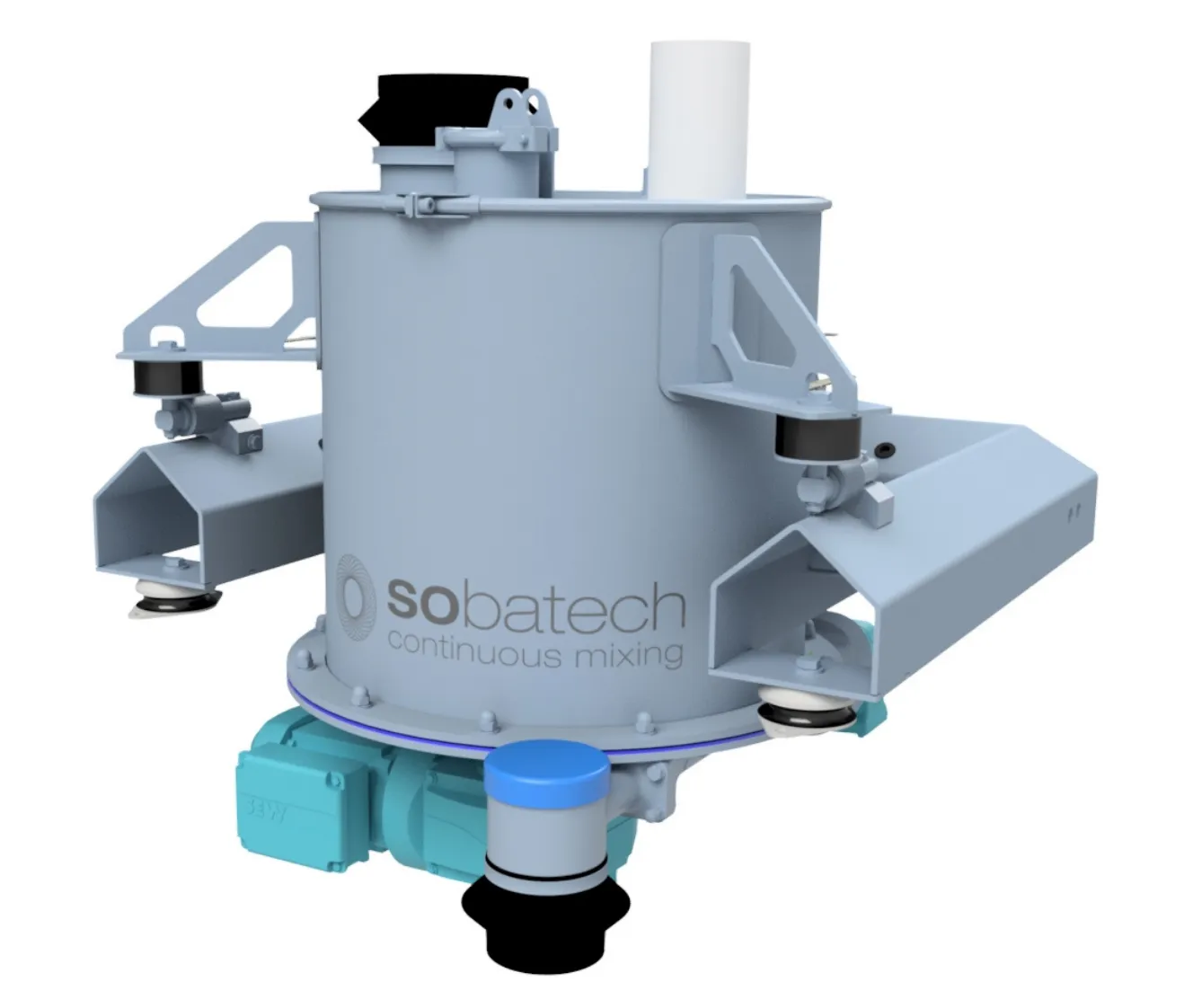

The mass flow meters operate using a vibrating tube energized at a constant frequency. As liquid flows through the tube, the resulting mass flow momentum induces a change in the vibration pattern, causing the tube to twist and produce a phase shift. This shift is measured to generate a linear output proportional to the flow rate. The use of Coriolis flow meters eliminates the need for compensation related to variations in temperature, viscosity, or pressure.

.webp)

.webp)

%20hydrator.webp)

.webp)