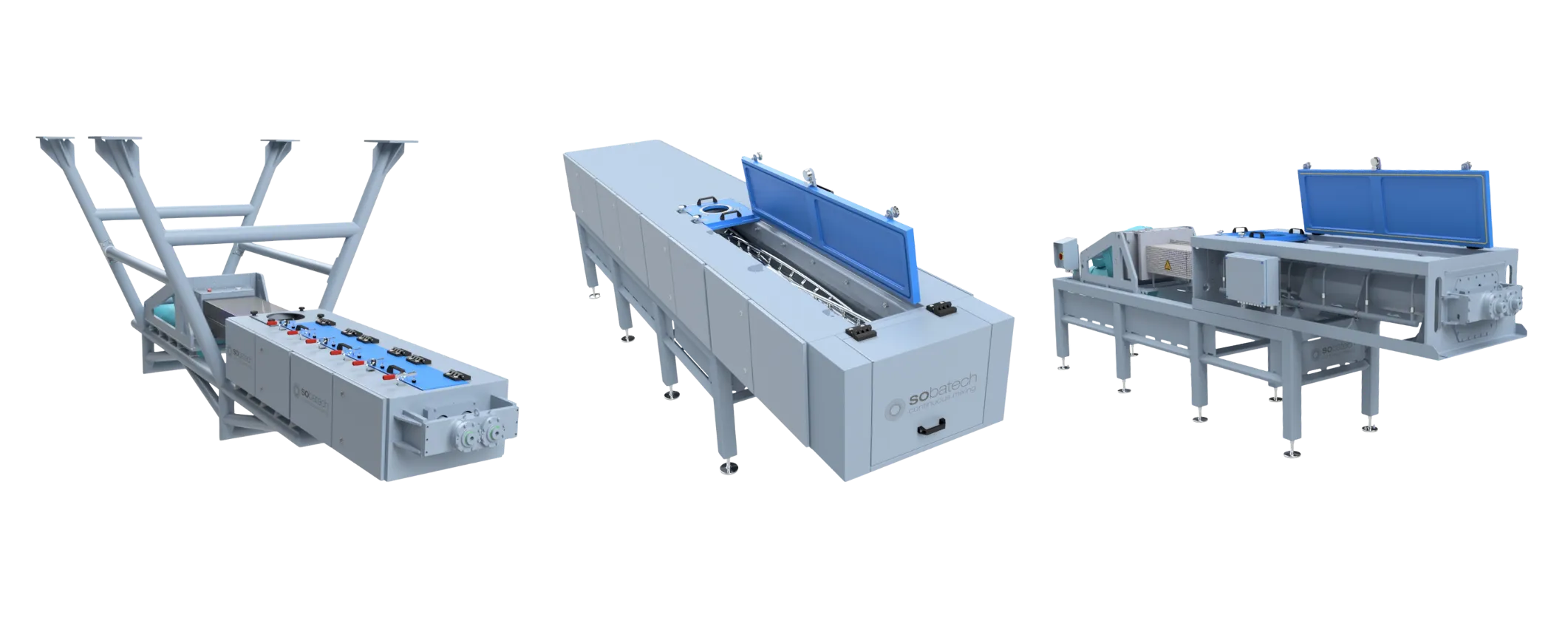

The Sobatech continuous mixing system consists of two distinct mixing phases. In the first phase, ingredients are evenly and accurately distributed across the full mass. In the second phase, controlled mechanical energy is applied to develop the desired product properties.

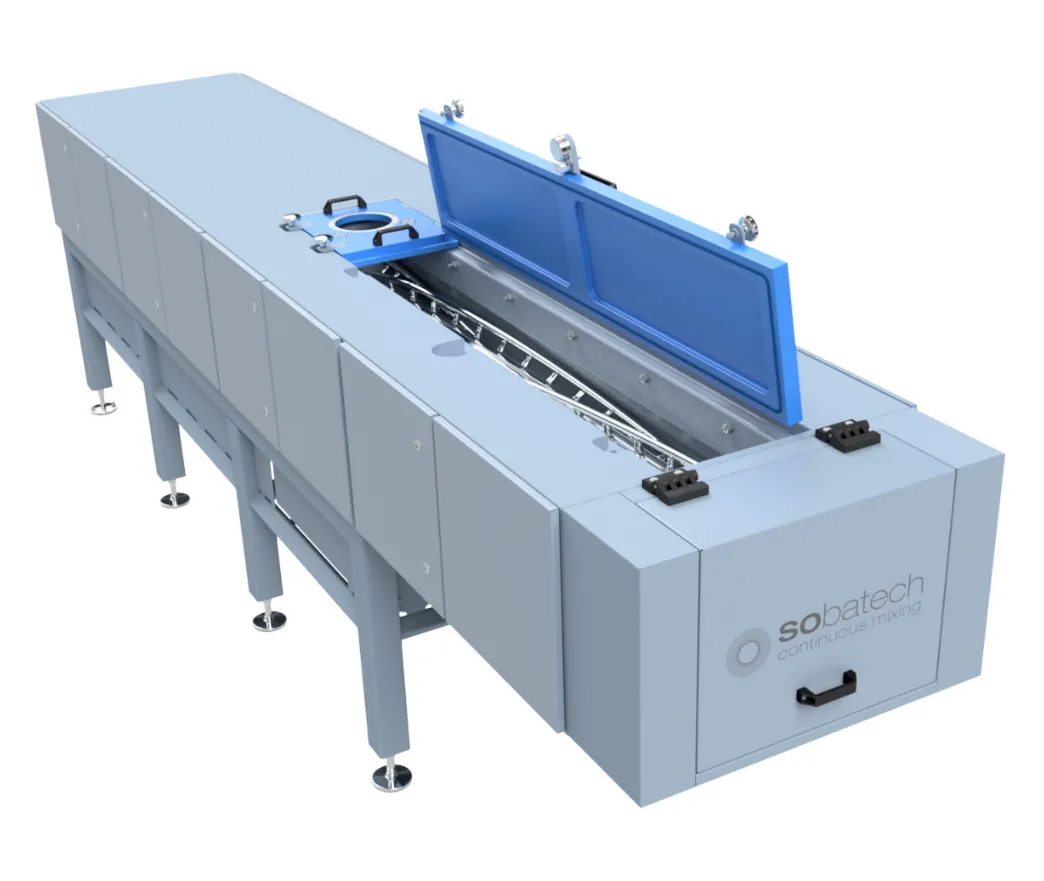

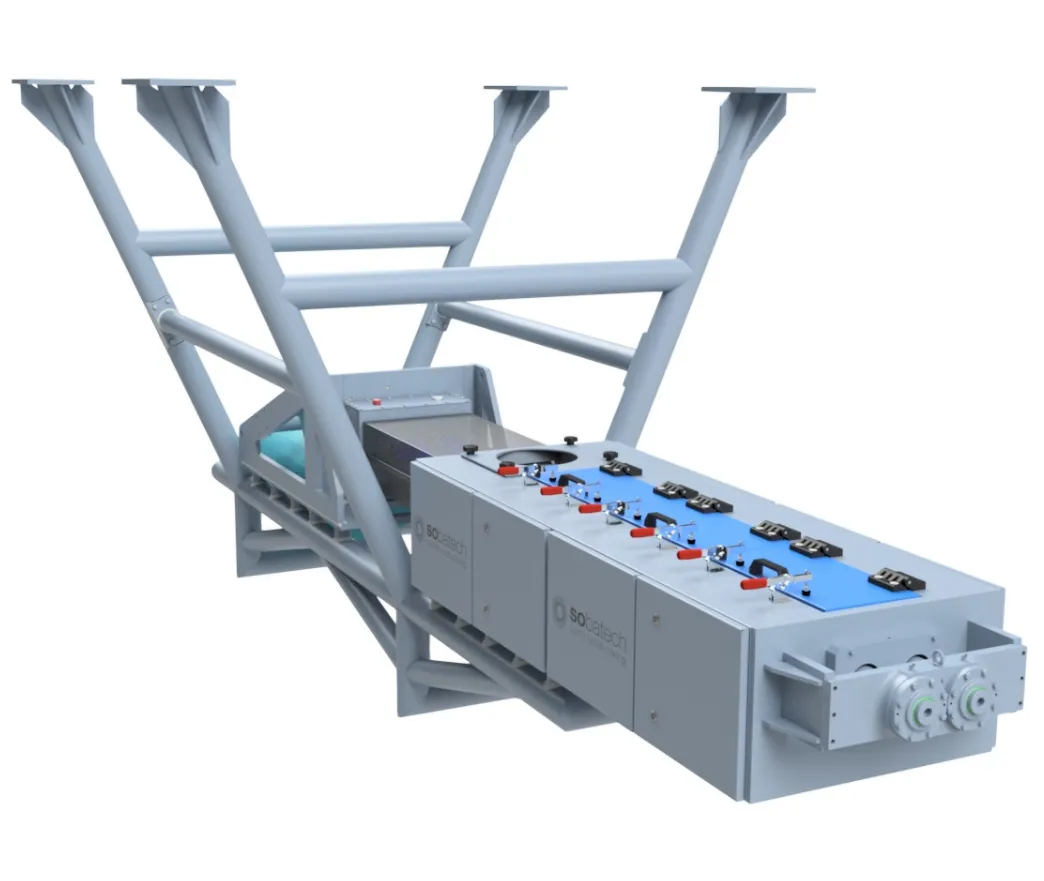

Phase 1 mixing: the homogenizer

After dosing, the powder ingredients fall from the weighing system through the homogenizer into the continuous mixer. During this fall, liquid ingredients are injected at a predefined sequence and medium pressure. This non-mechanical blending method ensures a uniform distribution of raw materials and promotes optimal water absorption.

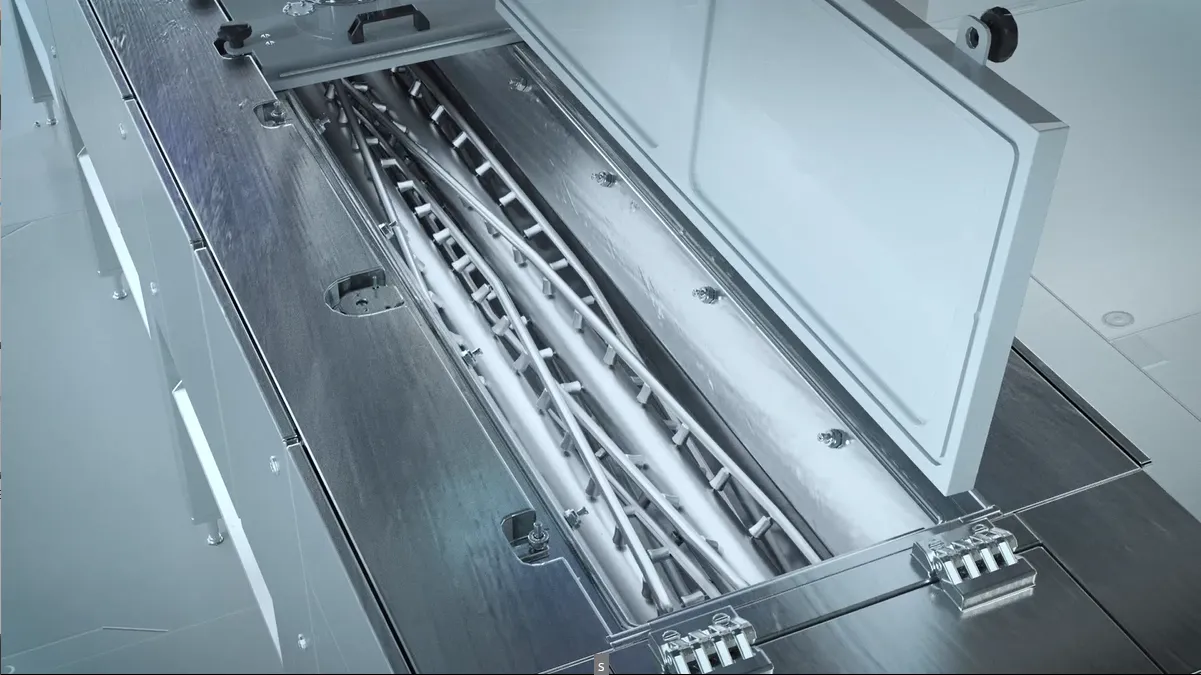

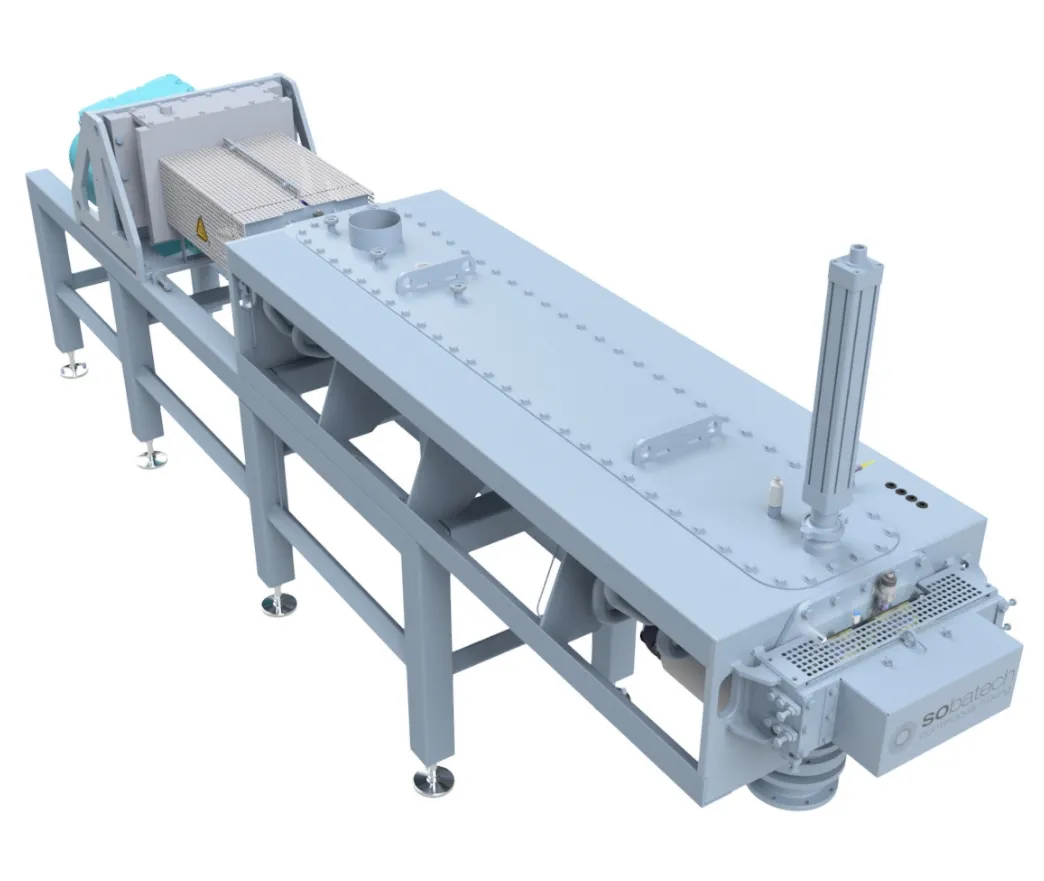

Phase 2 mixing: the continuous mixer

In this stage, the blended ingredients enter the continuous mixer, where contra-rotating mixing tools apply mechanical energy to develop the product structure. The mixer’s high product-tooling ratio—meaning a small volume of product compared to a large volume of tooling—ensures that most of the energy is effectively transferred into the product. This results in consistent and efficient mixing performance.

Both the homogenizer and continuous mixer follow a first-in, first-out (FIFO) principle, ensuring a uniform processing time for all product particles.

.webp)