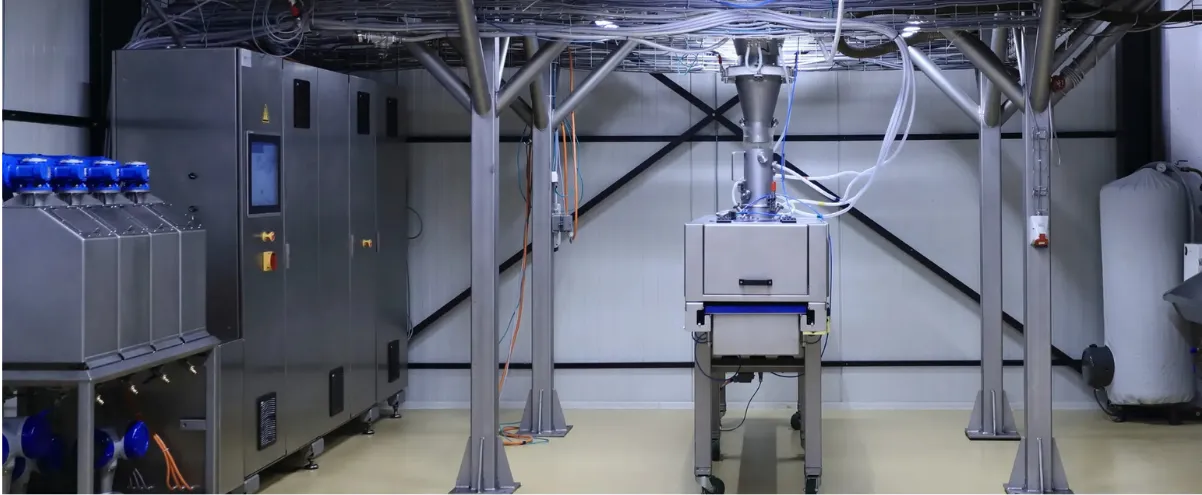

At Sobatech, we are committed to providing a seamless, efficient, and professional testing experience. Our demonstration facility is equipped with a complete continuous processing line, allowing you to replicate your full production process — from dosing and mixing to forming and baking — using your own ingredients and recipe. The center includes platform structures, gravimetric powder dosing systems, and a wide range of liquid dosing solutions with various measuring principles.

At the heart of the facility is our advanced continuous mixing system, featuring adjustable low to high shear mixing tools, integrated dough temperature control, vacuum processing capabilities, and an automatic CIP (clean-in-place) system. Additional equipment includes a homogenizer (non-mechanical blending), a continuous bulk fermenter, and a discharge belt, all governed by modern electrical controls and automation.

To benchmark or compare with traditional methods, a batch mixer is also available, along with manual sheeters, forming options, an industrial oven, weighing scales, and more — giving you everything you need to thoroughly test and validate the performance of continuous mixing for your specific application.

.webp)