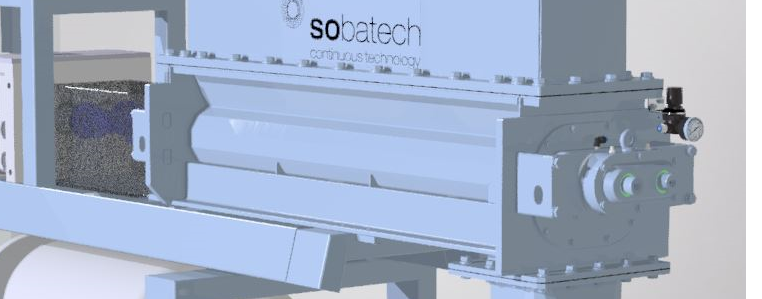

Vacuum mixer

Continuous degassing system

Vacuum mixing is a process used in various industries, including pharmaceuticals, food, and cosmetics, to mix and homogenize ingredients under vacuum conditions. Sobatech’s vacuum process involves a continuous degassing system creating a low-pressure environment by removing air from the mixing chamber. By following this process, the formation of air bubbles can be prevented, which can ultimately impact the quality and density of the final product. Sobatech’s continuous degassing system includes contra-rotating mixing tools that ensure that constantly new product is being brough to the surface. This ensure a consistent product density and consistency.

Product specification

Some of the benefits related to Sobatech’s continuous vacuum system are:

- Vacuum mixing can have a positive effect on the appearance of cosmetics due to the removal of air bubbles in the products. This results in a smooth and homogenous mixture.

- The shelf life of a certain product can be improved by vacuum mixing, as it reduces the risk of oxidation and the growth of bacteria.

- Vacuum mixing also allows for the creation of products with a higher concentration of active ingredients. This is because the vacuum process helps to break down the ingredients and disperse them evenly throughout the product.

- Eliminates the need for preservatives an stabilizers, which improves the quality and shelf life of the final products.

- Helps to preserve the nutrient content of the food.

- Reduces the processing time and cost of producing food products. Due to the low-pressure environment, the boiling point of the ingredients is reduced, which speeds up the cooking process.

- Ensures that the food products have a consistent texture, flavor, and aroma.

- Continuous vacuum mixing makes final product density controllable