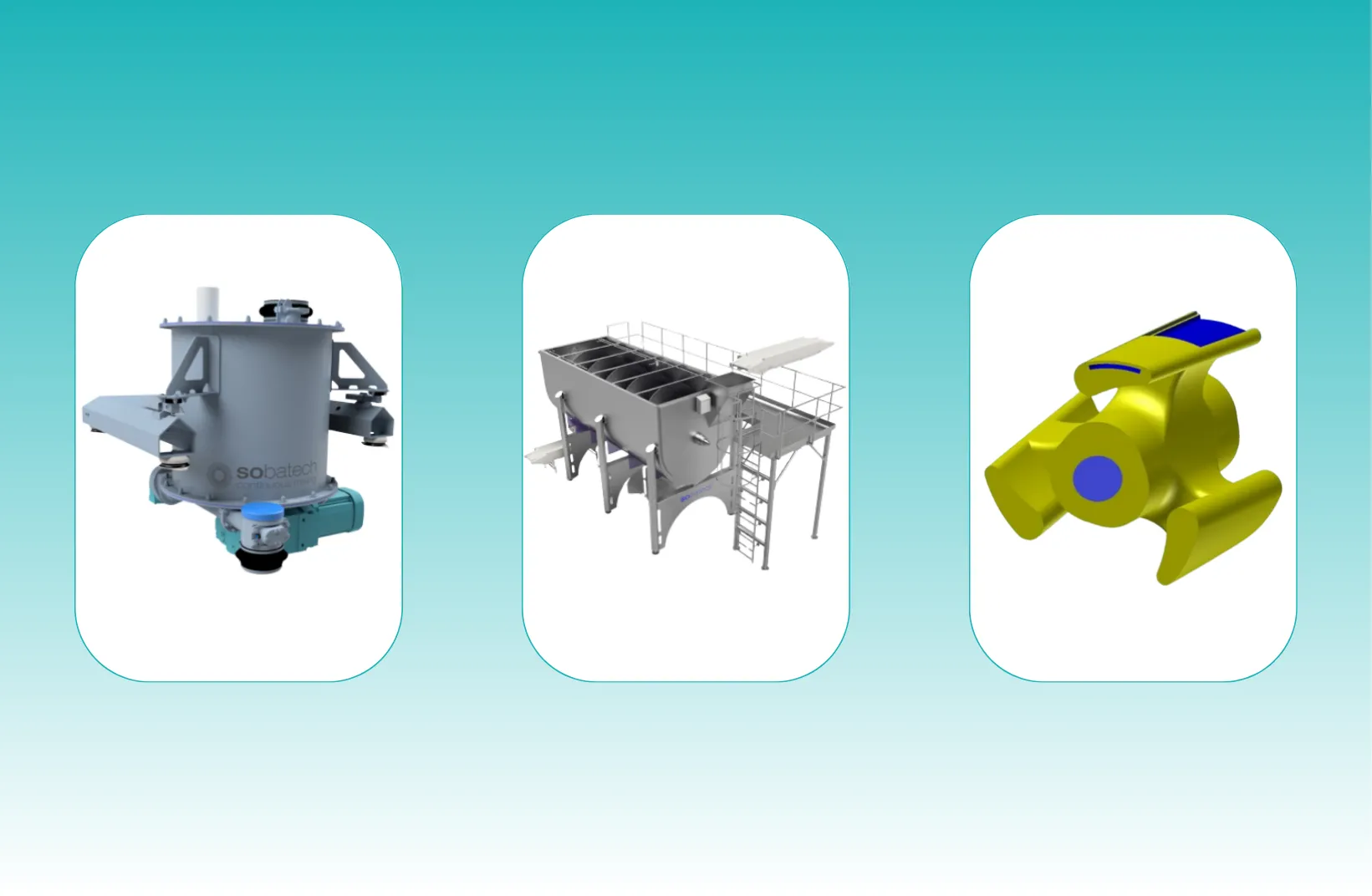

In 2008, Sobatech moved to new premises at Karveelweg 9 in Maastricht, the Netherlands, providing space for further growth and innovation. Initially specializing in continuous mixing systems, the company soon saw potential to enhance dosing technology. That same year, Sobatech developed its own dosing systems, followed by proprietary hardware and open-source, high-accuracy loss-in-weight software.

In 2011, Sobatech introduced its first continuous bulk fermenter, enabling products to rest under controlled conditions for optimal development. By 2015, the company expanded its range of kneading axes by including complex milled kneading tools, enabling to process both high- and low-viscosity products. This advancement opened new markets beyond food, including pharmaceuticals, chemicals, and cosmetics.

In 2016, Sobatech launched its continuous vacuum system, creating a low-pressure environment that prevents air bubble formation in products. A year later, it introduced Hot & Cool technology, enabling precise cooling where it heats up during the mixing process. In 2020, Sobatech launched the continuous TVP hydrator, designed to hydrate voluminous masses over time.

.webp)

.webp)

.webp)