Precise dough temperature control in continuous mixing

.webp)

.webp)

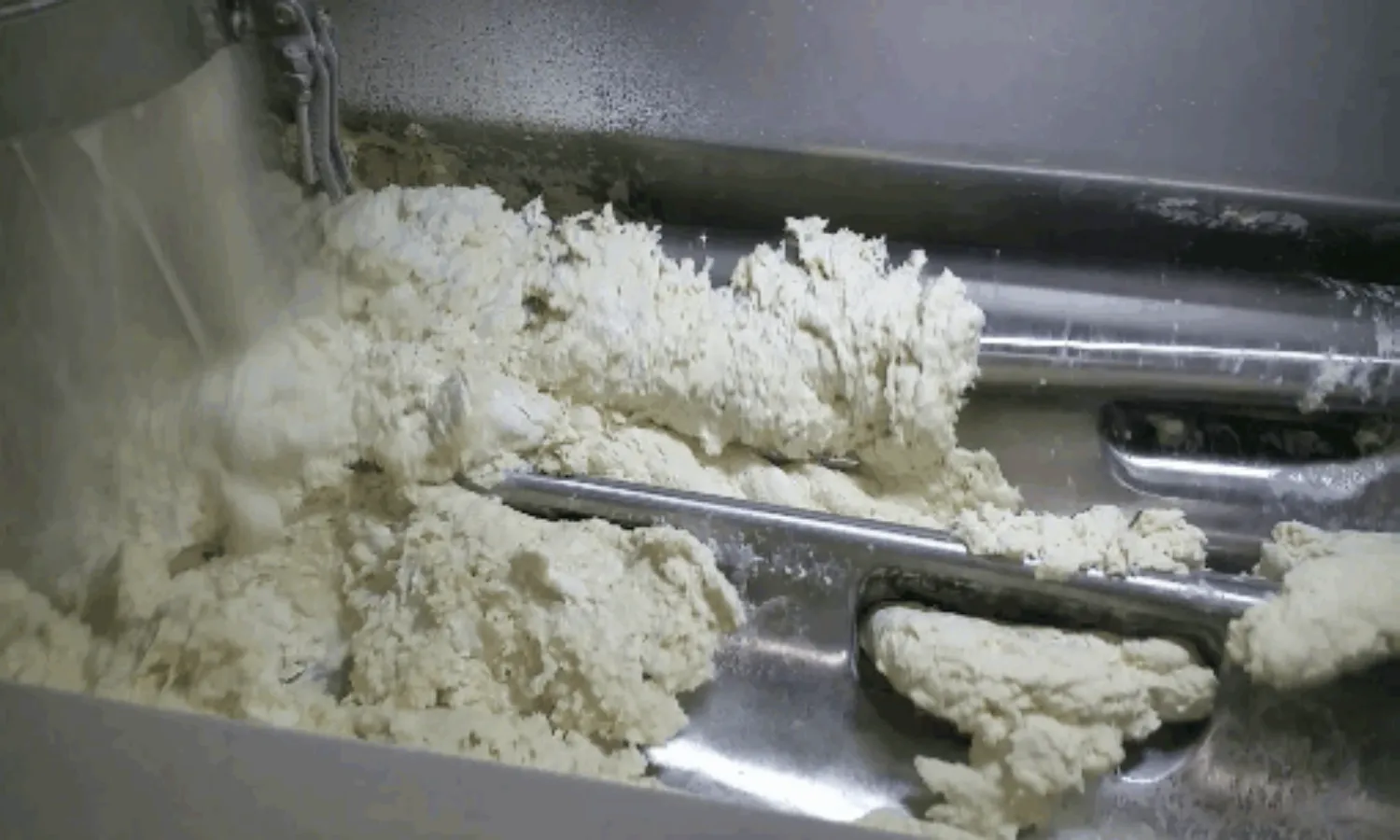

Dough temperature is a critical performance indicator in evaluating dough quality. Whether a recipe requires low dough temperatures (15–17°C) or higher temperatures (30–35°C), even minor fluctuations can significantly impact dough structure and the final product. As such, precise temperature control is an integral feature of Sobatech’s continuous mixing systems.

In continuous mixing, every portion of dough receives identical mechanical treatment, which enables a stable and consistent dough temperature throughout the process. This is typically achieved by controlling the temperature of the process water—an ingredient in the dough formulation. The system blends water from three separate temperature sources to achieve the desired setpoint:

By fine-tuning this mix, Sobatech ensures stable dough temperatures regardless of external conditions or batch size.

For applications requiring enhanced thermal control, Sobatech offers an optional double-jacketed mixing chamber. This design significantly increases the contact surface between the dough and the chamber wall, providing effective heat transfer for additional cooling or heating. To determine whether a double jacket or alternative solution is needed, Sobatech provides a proprietary temperature calculation tool—available upon request.

For extreme temperature applications—whether cooling to process frozen doughs or heating to initiate inline cooking—Sobatech has developed its innovative HOT & COOL technology.

This solution features hollow, milled mixing tools that enable direct temperature regulation at the point of friction—where heat is naturally generated during mixing. By heating or cooling at the exact location of energy input, Sobatech ensures precise thermal management throughout the continuous mixing process.

As a result, the system can:

With these technologies, Sobatech delivers unparalleled control over dough temperature—helping manufacturers maintain consistent product quality, meet exacting recipe specifications, and streamline production across a wide range of applications.

.webp)

.webp)