Often, the fundamentals for success in business life lie in the ability to adapt to a constantly changing marketplace. As a result, Industrial food producers often produce a large variety of SKU’s (stock keeping units). Not long ago, continuous mixers were perceived to not be suited for such production environments. To open the discussion on flexibility of a continuous mixer, flexibility has to be divided in (1) flexibility in relation to the variety of product types one mixers needs to run and (2) flexibility in relation to the variety in throughput one mixers needs to hold.

Product types

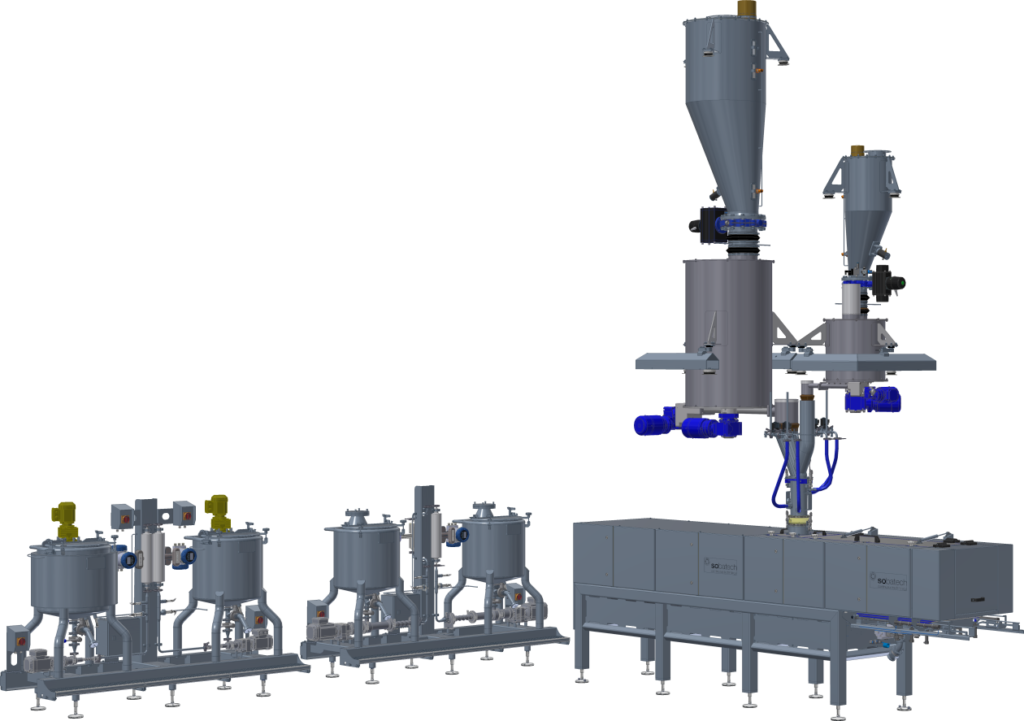

Sobatech designs its mixing tools to the desired energy input needed to develop a certain product category properly. The flexibility a batch mixer has with time, has a continuous mixer with speed. Sobatech controls the RPM (shaft speed) of the contra rotating mixing tools to steer the desired product development. Besides speed, the continuous mixer can play, in a certain band width, with throughput. These two factors allow customers to run different recipes on one and the same continuous mixer.

Amount of recipe changes

The maximum amount of changeovers that are recommended per day strongly depend on how much the recipes differ from eachother. Sobatech has customers who automatically change their premix every 15 minutes. Solely changing the composition of the premix is what we call minor changeovers. Such recipe changes allow for the second dough type to simply push out the first dough type. This process can happen in automatic mode and is well suitable for a continuous production. Yet, there are also recipe changes in which color or allergens play a significant role. For such changeovers, Sobatech recommends to have runs of at least 4 hours.

Flexible dosing

Another part of the continuous flexibility is the location of the dosing inlets. In the Sobatech continuous mixer, it is possible to dose flexibly. If you need to dose certain inclusions (such as raisons, hazelnuts, chocolate chips) in a stress-free way into the dough, Sobatech can introduce them at a later stage in the mixing process. It is the rheology of the dough, shape of the mixing tools and the forces that the inclusions can handle to keep them in their initial shape and size. Generally, Sobatech includes a stress-free part in the mixer tooling at the location where the inclusions enter the mixing chamber. In other words, Sobatech ensures inclusions are blend into the mass by very low kneading intensity.

Cleaning

Sobatech’s continuous mixers offer a fully automated cleaning in place system. This automated process eases the cleaning procedure in between changeovers. Check out the process here.

More information? Contact us!