During chocolate conching, a homogeneous flowing suspension is prepared from an inhomogeneous mixture of particulates (sugar, milk solids & cocoa solids), and cocoa butter by prolonged mechanical action and the staged addition of dispersants.

At Sobatech, we are all about creating the perfect chocolate experience. That means achieving a smooth, delicious mixture – a fancy way of saying a homogeneous flowing suspension. Here is the challenge: finding the ideal mixing and chocolate conching time. It is all about balance. We want it to be quick enough to take advantage of our super-efficient technology, but slow enough to remove moisture and develop that rich, decadent chocolate flavor you love. That is the sweet spot we are constantly striving for – shorter processing times without sacrificing taste. And with Sobatech, you can achieve that perfect balance!

Elements Forming the Basic Principle

- System consists out of kneading and shearing elements.

- High shear (until 25 wh/kg)

- Extreme high shear (25 wh/kg+)

- Low product-tooling ratio.

- Open surface on top to allow water and acids to evaporate.

- Precise temperature control (by heating/cooling the mixing chamber).

- Traditional conch temperature 50 C – 70 C.

- Controlled TIP-speed (speed of the mixing tool relative to the mixing chamber).

- The motor torque remains maximal until the effect of the lecithin injection.

- Expected energy savings of up to 50% compared to existing conch systems.

- Depending of refining stage mixing and conching in one system.

- Significant lower CAPEX/OPEX compared to existing systems.

Homogeneity

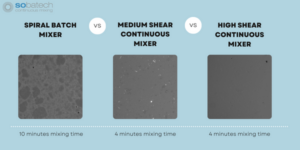

Homogeneity in chocolate conching refers to the process of achieving a smooth, uniform texture and flavor in chocolate production through mixing. By using a continuous mixer, a uniform chocolate mixture can be achieved in a shorter mixing time than with traditional chocolate conching methods.