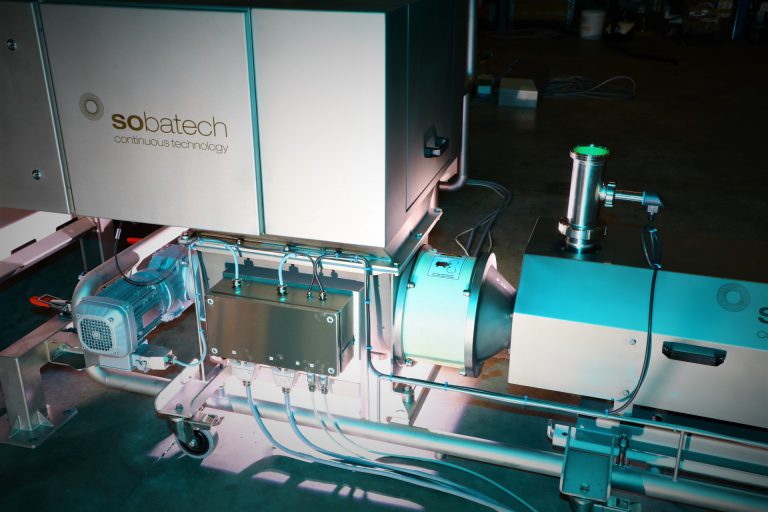

Sobatech is proud to present the first pictures of the latest continuous production line for Namkeen in Asia. The continuous mixer is capable of doing 5.000 kg of dough per hour.

Continuous dosing

The continuous production line for Namkeen includes a weighing belt for dosing the powders. Besides that, it includes two dosing pumps for dosing the high viscous liquid ingredients. The weighing belt measures the weight reduction of the premix per time unit. It doses the powders via the homogenizer in the continuous kneader. In the homogenizer, the powders are injected with the liquids. After that, the ingredients enter the mechanical kneading part.

Continuous mixing

The innovative tools of the continuous kneader, in phase 2, are responsible for the controlled flow of dough throughout the machine. The combination of a relative small amount of dough in the mixing chamber with a relatively high volume of tooling, result in a remarkable high energy efficiency. A large part of the energy developed by the tooling is put into the mass. At the mixer outlet, there is a pump located that transports the mass to an extruder head.