Dough temperature is one of the key performance indicators used by bakeries to evaluate the quality of their dough. No matter if the dough temperature needs to be low (around 15 to 17° C) or high (in the range of 30-35° C); fluctuations in dough temperature have an immediate effect on the dough make-up and end-product. Therefore, controlling dough temperature is an essential part of Sobatech’s continuous dough mixing systems.

PROCESS WATER

On a continuous mixing system, each piece of dough gets the same mechanical treatment. Therefore, dough temperature is kept constant at all times. Generally, dough temperature is controlled by means of cooling or heating the process water. This is done through mixing the water that is part of the recipe from 3 temperature sources:

- Cold = 4 – 5° C

- Ambient = 12-15° C

- Warm = 20-22° C

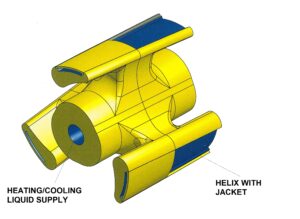

DOUBLE JACKETS

Also, the continuous mixer can be equipped with double jackets providing additional cooling (or heating) if required. The continuous mixing system creates a relatively large contact surface to the mixing chamber making this an effective way of controlling dough temperature. Sobatech’s temperature calculator that is available upon request is able to determine the need of double jackets and/or Sobatech’s HOT & COOL technology.

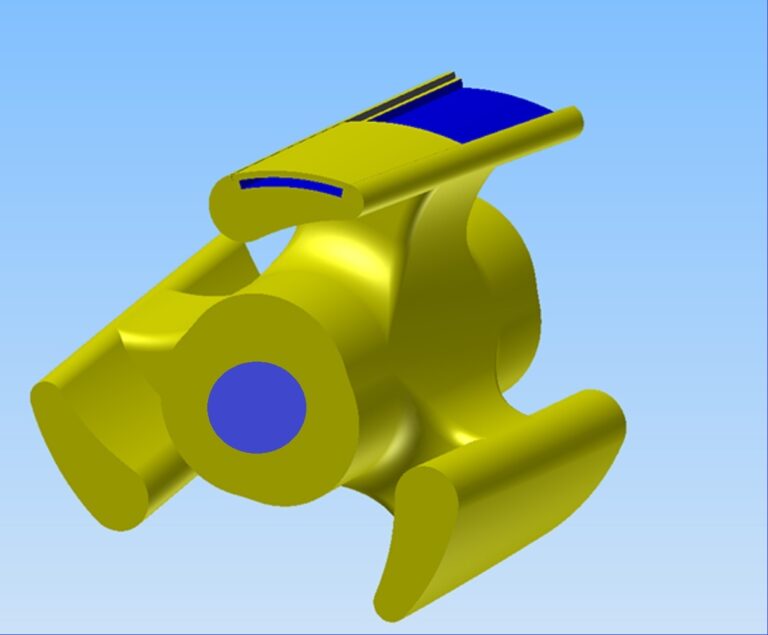

HOT & COOL

For extreme low or high dough temperatures, Sobatech invented its so called ‘HOT & COOL’ technology. This technology allows for Sobatech milled mixing tools to be made hollow. Making the mixing tools hollow allow to heat up or cool down at the exact point of friction. In other words, Sobatech’s continous dough mixers can cool precisely there where it heats up. As a result, Sobatech can now cook inline but can also handle frozen doughs in a very gentle way.