Constant dough consistency with continuous mixing

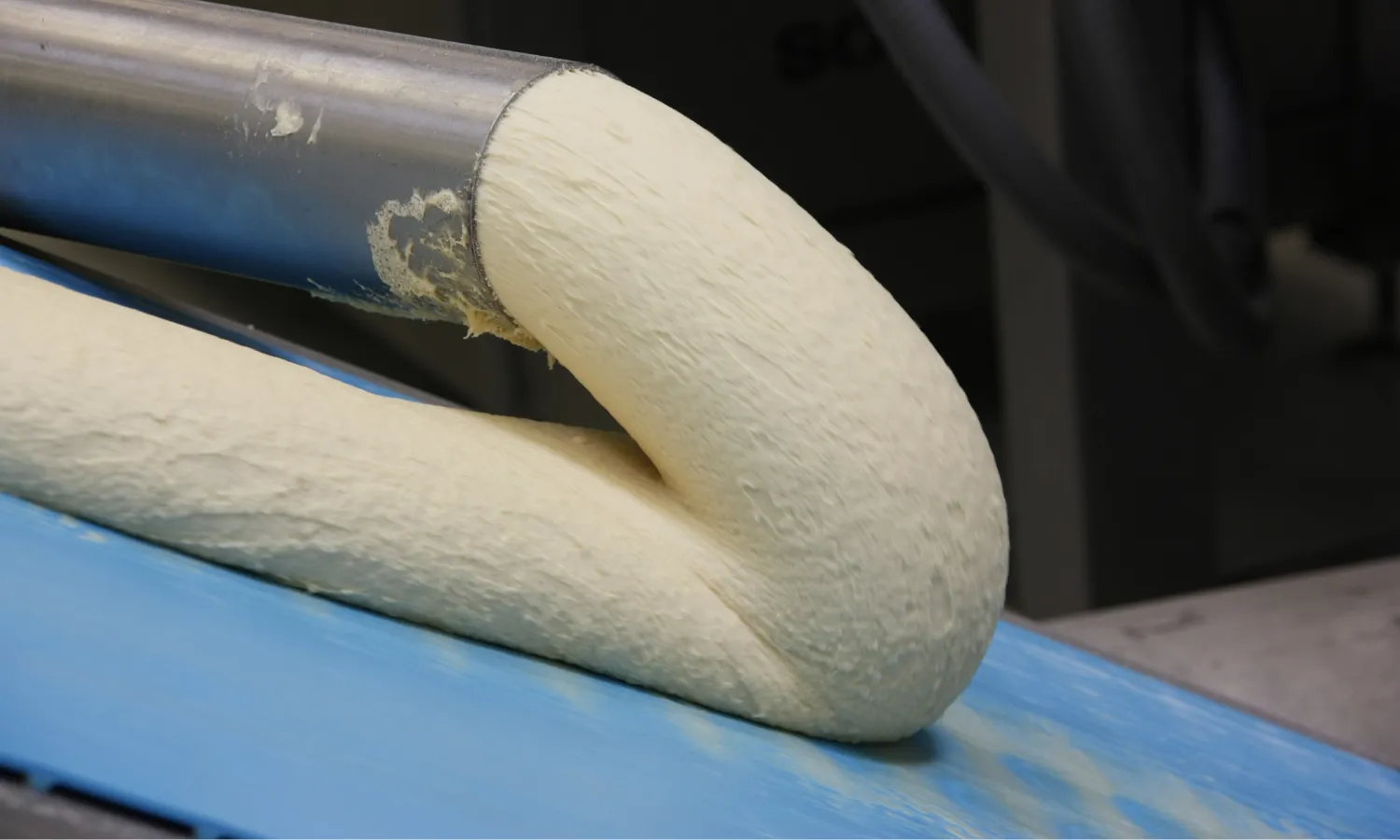

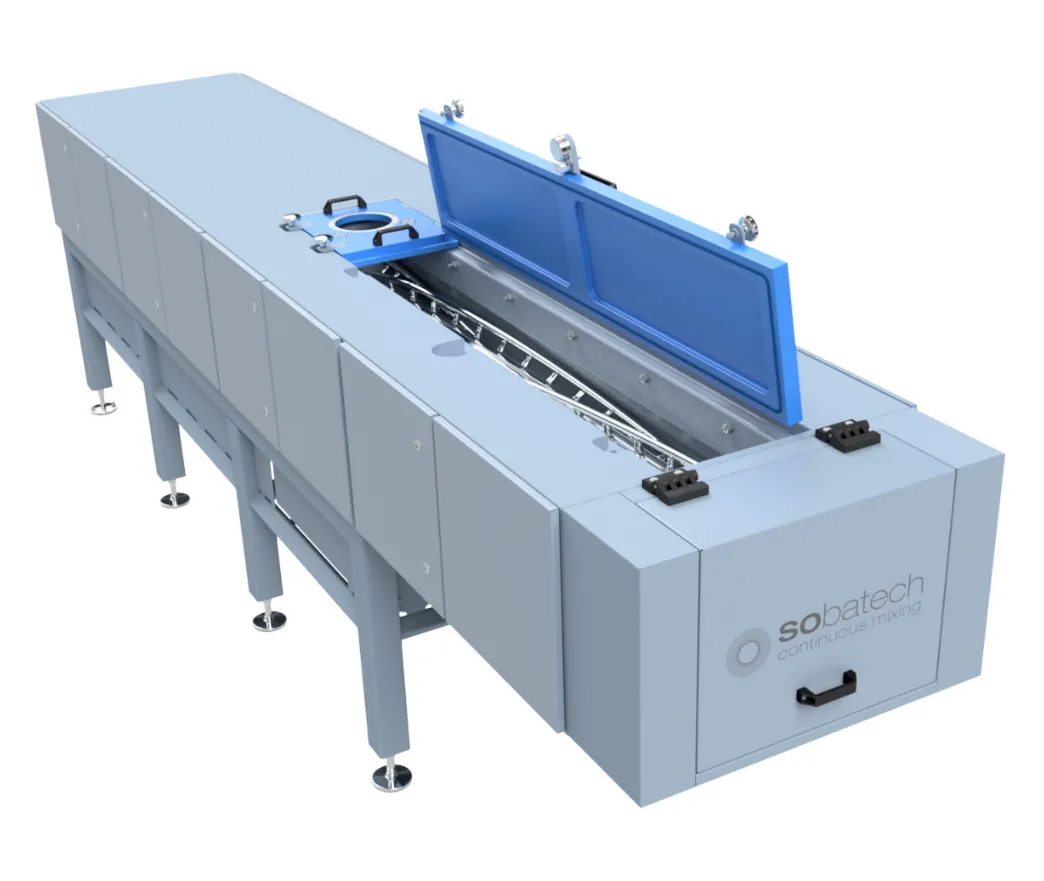

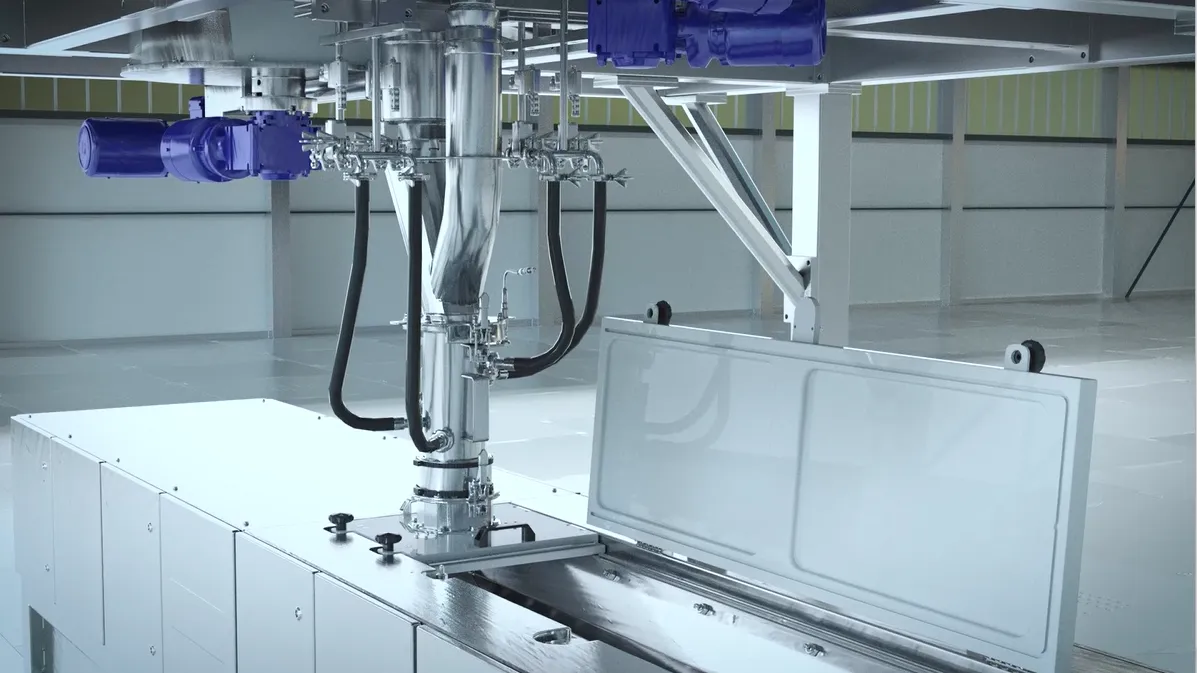

A continuous mixing system constantly delivers a consistent flow of product. This is what is called ‘constant consistency’. Each piece of dough has had the same mechanical treatment and age. Traditional dough production, however, often results in undesirable batch to batch dough variations. The age differences between each batch cycle result in quality differences that might be visible throughout the entire production process.