Flexibility on a continuous mixer

In today’s fast-paced and ever-evolving food industry, production flexibility is no longer optional—it’s essential. Industrial food manufacturers are increasingly required to produce a wide variety of SKUs to meet diverse consumer preferences. While continuous mixers have historically been perceived as less adaptable to such dynamic demands, this view is rapidly changing.

Sobatech defines flexibility in continuous mixing through two core dimensions:

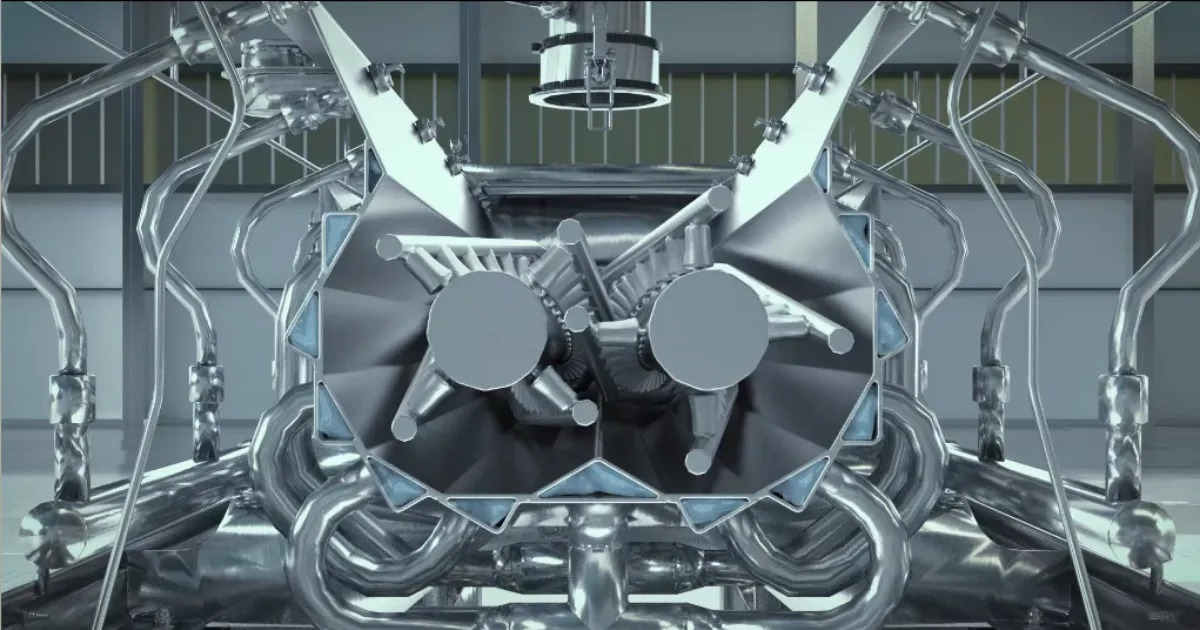

Sobatech engineers its mixing systems around the specific energy input (Wh/kg) needed for optimal product development. In batch mixing, development is typically controlled by time, whereas in Sobatech’s continuous systems, it is governed by the shaft speed (RPM) of the contra-rotating mixing tools.

By adjusting the RPM, operators can fine-tune dough development, enabling multiple recipes to be processed on a single mixer. This approach not only enhances product variety but also contributes to throughput flexibility within a defined operating range.

The frequency and complexity of recipe changeovers depend on the differences between products:

Another key element of Sobatech’s flexibility is the configurable placement of dosing inlets. The system allows for the precise, late-stage addition of sensitive inclusions—such as raisins, chocolate chips, or hazelnuts—without compromising their integrity.

This is made possible by a dedicated low-intensity mixing zone, designed specifically to preserve the shape, size, and texture of inclusions. The system is tailored to the rheological properties of the dough and the mechanical tolerance of the added ingredients

Sobatech’s continuous mixers are equipped with a fully automated Cleaning-In-Place (CIP) system. This functionality simplifies and accelerates cleaning between product changeovers, supporting efficient, uninterrupted production.

Sobatech’s continuous mixing solutions offer:

With these features, Sobatech mixers are ideally suited for industrial manufacturers who require both high efficiency and maximum production flexibility.

.webp)

.webp)