Optimize production efficiency: how to choose the right mixing technique

.webp)

.webp)

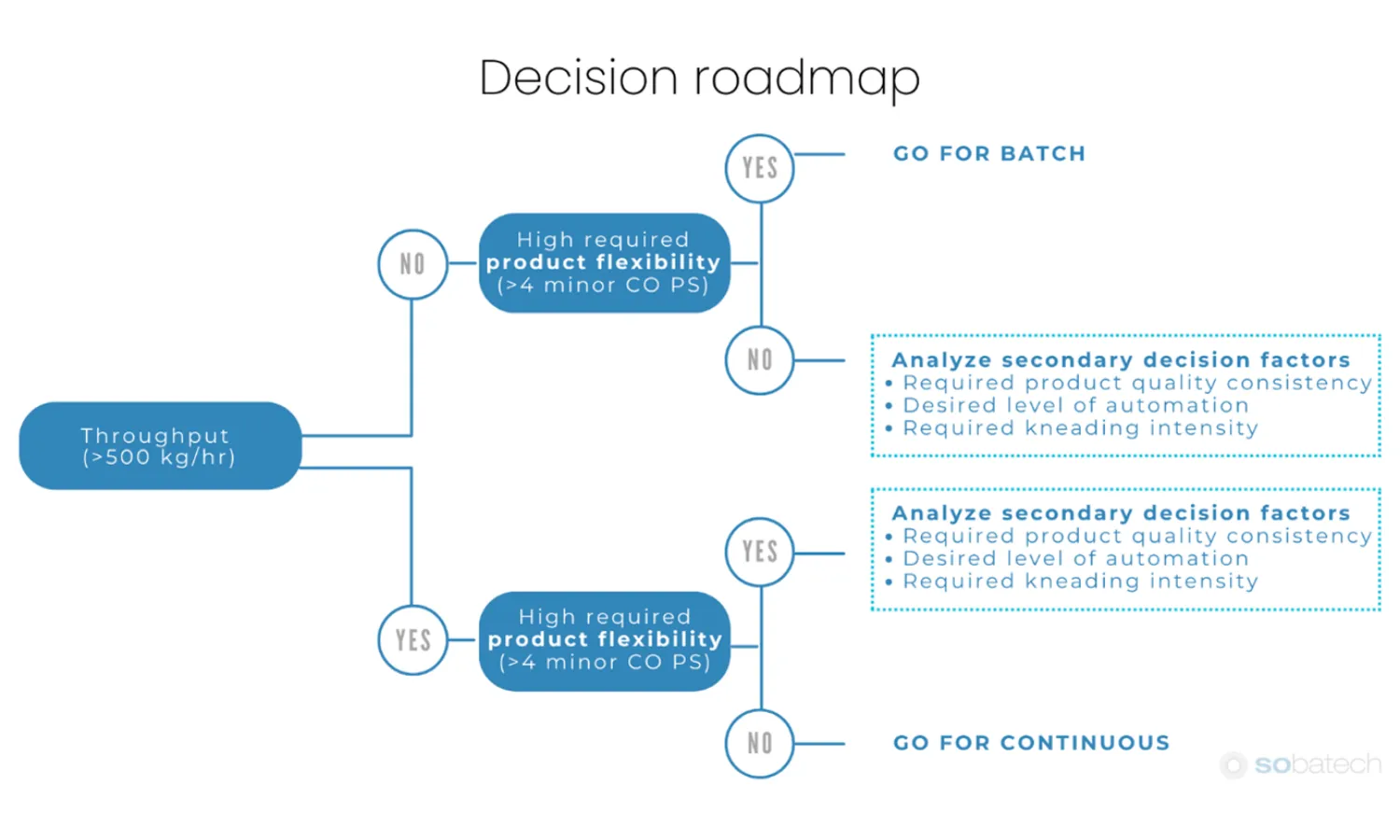

Sobatech has developed a comprehensive mixing technology decision roadmap to help food and non-food production companies select the most suitable mixing technique for their specific operations. The roadmap is based on two primary decision factors:

Understanding these factors enables manufacturers to make informed choices that improve consistency, reduce costs, and optimize production processes.

Figure 1: Decision roadmap

The first primary decision factor revolves around throughput per hour. As operations scale and require larger quantities of ingredients, batch mixing can become uneconomical due to increased manual labor and the subsequent impact on product quality traceability. Sobatech has identified that when throughput exceeds 500 kg/hr, continuous mixing becomes more appealing than batch mixing. Continuous mixers offer better product quality control through computer automation and can handle throughput variations more efficiently. For example, if a mixer needs to feed multiple make-up lines with varying capacities, a continuous mixer can adapt without compromising quality, unlike a batch mixer where a decrease in the amount of batches can lead to longer waiting times which will result in higher quality inconsistencies.

The second primary decision factor is the required recipe flexibility, specifically the number of different products produced on one mixing system. Generally, the more frequent recipe changeovers within an operation, the less appealing continuous mixing systems may seem. However, it is a misconception to believe that continuous mixing systems are only suitable for mono-lines. Understanding the nuances of major and minor changeovers can help clarify this.

A major changeover requires a complete system washdown before producing new dough, especially when dealing with differences in color or allergens. Given the effort involved, it is efficient to run these systems for at least four hours on an automated line. Minor changeovers, where one dough pushes out the previous one, are ideal for continuous mixing systems. Modern dosing systems enable quick recipe changes at the push of a button, allowing seamless transitions without stopping production. Continuous mixers can also speed up cleaning, often matching batch mixers, and may feature automated cleaning-in-place systems.

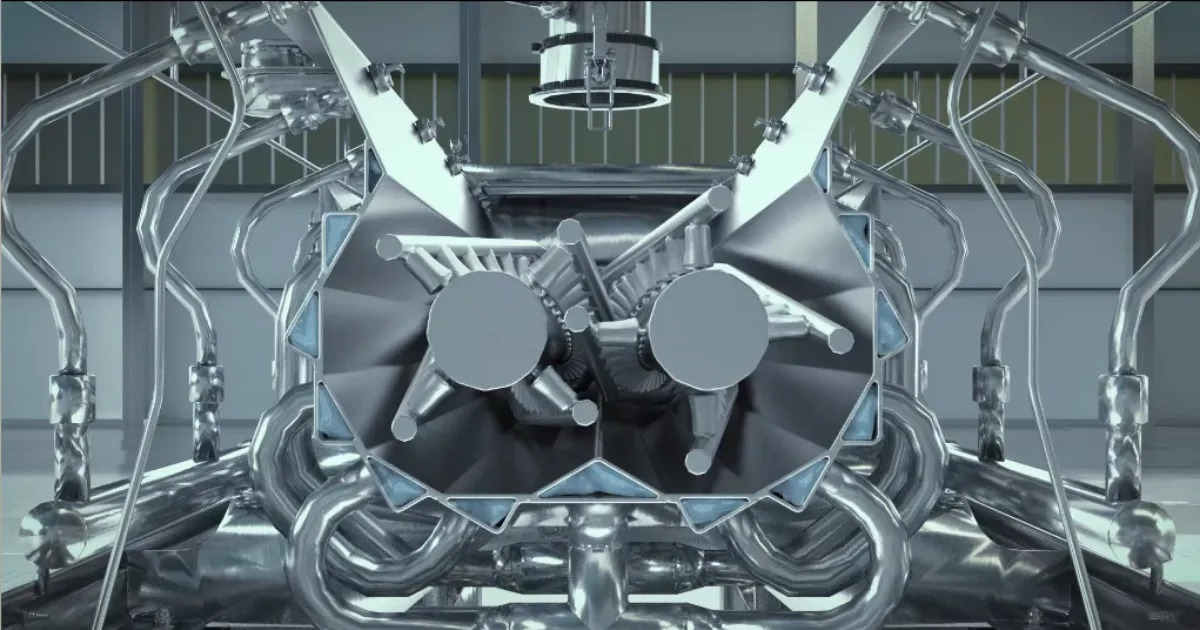

The second aspect of product flexibility is the required variety in kneading intensity, measured as Specific Mechanical Energy (SME). Different products need different SME values. In batch mixers, increasing kneading intensity means extending mixing time, which reduces throughput. On the other hand, continuous mixers achieve higher kneading intensity by increasing the RPM of the mixing tools, without affecting throughput within a reasonable range of +/- 40% of the mixing speed. In sum, time in batch mixers equates to speed in continuous mixers, providing greater flexibility without sacrificing throughput.

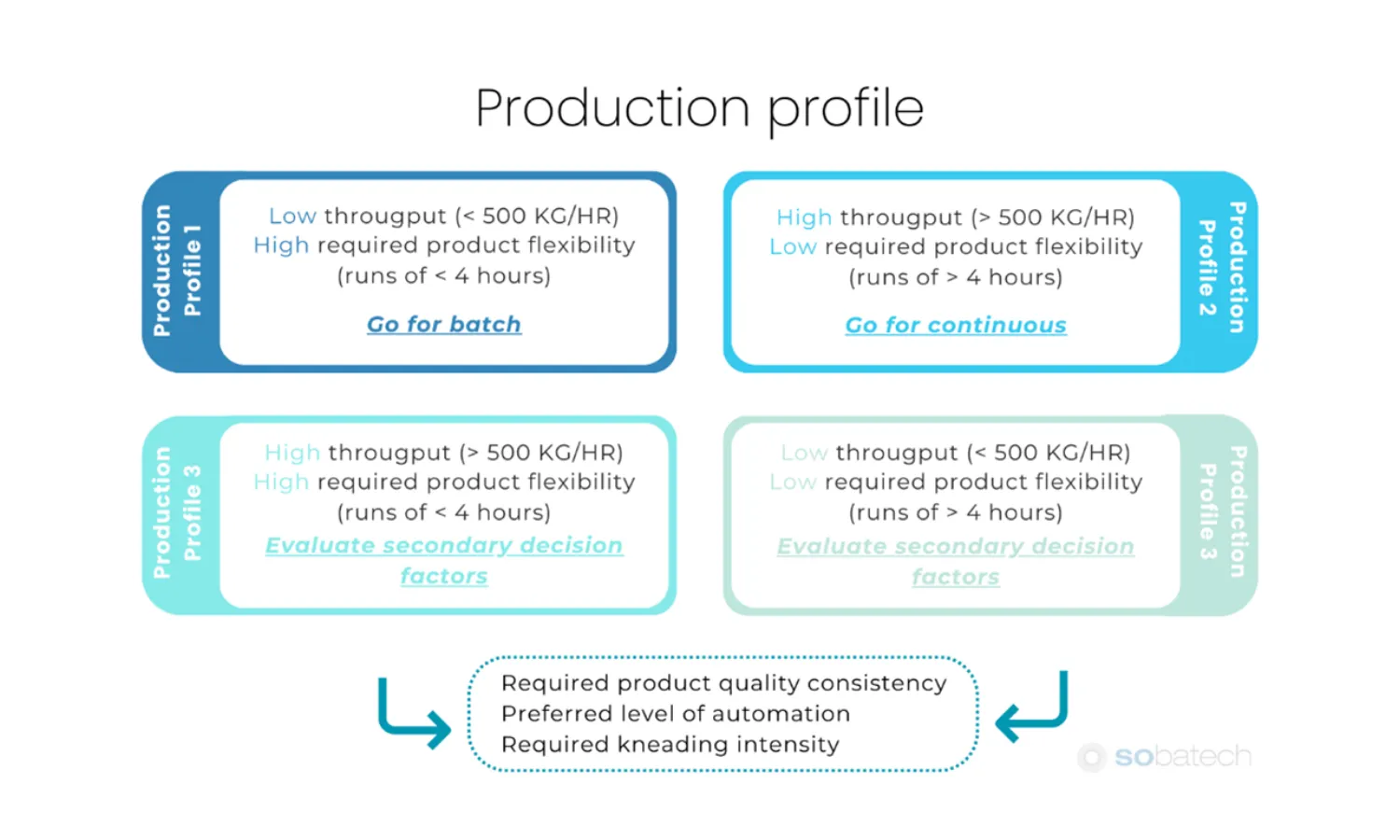

Figure 2: production profiles

After addressing the primary decision factors of throughput and required product flexibility in manufacturing, four different production profiles can be identified (see figure 2). The production profiles help in discerning whether a batch or continuous mixing system should be utilized, based on the specific needs of the production process.

This production profile is characterized by a relatively low production rate, typically less than 500 kg/hr, coupled with a high requirement for product flexibility. This scenario occurs when production runs are shorter, generally under four hours, before necessitating a significant recipe change-over. For such a profile, a batch mixing system is recommended.

This production profile involves a relatively high production rate, exceeding 500 kg/hr, with a low requirement for product flexibility. This means that production can run for over four hours without the need for major recipe changes. In this case, one should definitely choose for continuous mixing.

These production profiles fall into a grey area where both batch and continuous mixing options need careful consideration. For these profiles, additional secondary decision factors are necessary to evaluate the suitability of each mixing technique further. These secondary factors help in making an informed decision when neither primary decision factors clearly dictates the optimal mixing method.

In case one falls into production profile 3 or 4, the decision-making process can be further refined by analyzing the so-called secondary decision factors. Sobatech introduces three secondary decision factors:

The first secondary decision factor is required product quality consistency. In batch mixing systems, variations between batches can impact baking requirements and labor costs. Continuous mixing, on the other hand, provides a constant product quality, as every piece undergoes the same fermentation process and aging. For production facilities where constant product quality is paramount, continuous mixing proves to be the superior choice. However, for factories where consistent product quality is not a necessity, batch mixing may be a better option.

Another crucial factor is the desired level of automation within the mixing process. Continuous mixing systems typically offer higher levels of automation, with the control system managing the dosing of ingredients and the overall mixing process. This automation reduces the reliance on operator skill and performance, ensuring consistent product quality. However, it also demands higher capital expenditure for setup, though operating costs are generally lower in the long run. For production plants that value labor-free operations, continuous mixing’s automated nature makes it an appealing option. However, not all production plants prioritize labor-free processes. Therefore, understanding your customer’s technological preferences is crucial.

The required kneading intensity also plays a significant role in choosing between batch and continuous mixing. Continuous mixers are particularly effective for products that require high kneading intensity, as they can deliver a higher amount of specific mechanical energy (SME) per unit of time. This is also one of the reasons why continuous mixers benefit larger operations and is known for its shorter mixing times.

Sobatech’s decision roadmap helps manufacturers make strategic choices between batch and continuous mixing systems based on:

Whether you are scaling up or refining your current setup, the right mixing strategy will directly enhance production efficiency and product quality.