5 reasons to go for continuous mixing

For many years, batch mixing has been the standard mixing technology in the food industry. However, rising demands for higher product quality and production efficiency have increasingly highlighted the limitations of batch mixing. As a result, food manufacturers are turning to continuous mixing systems to enhance throughput, improve consistency, and optimize their processes.

Below are five key reasons why continuous mixing might be the ideal solution for your production needs:

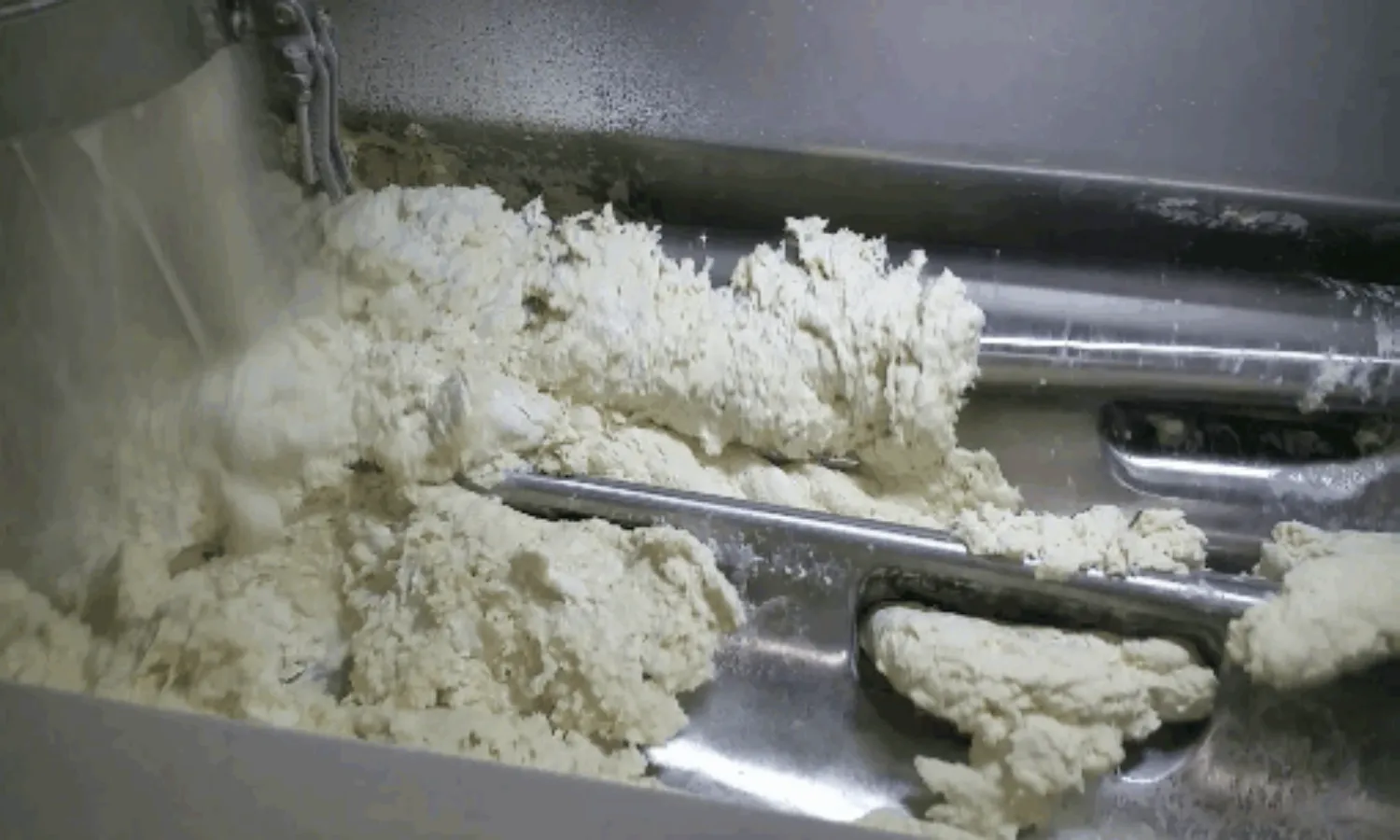

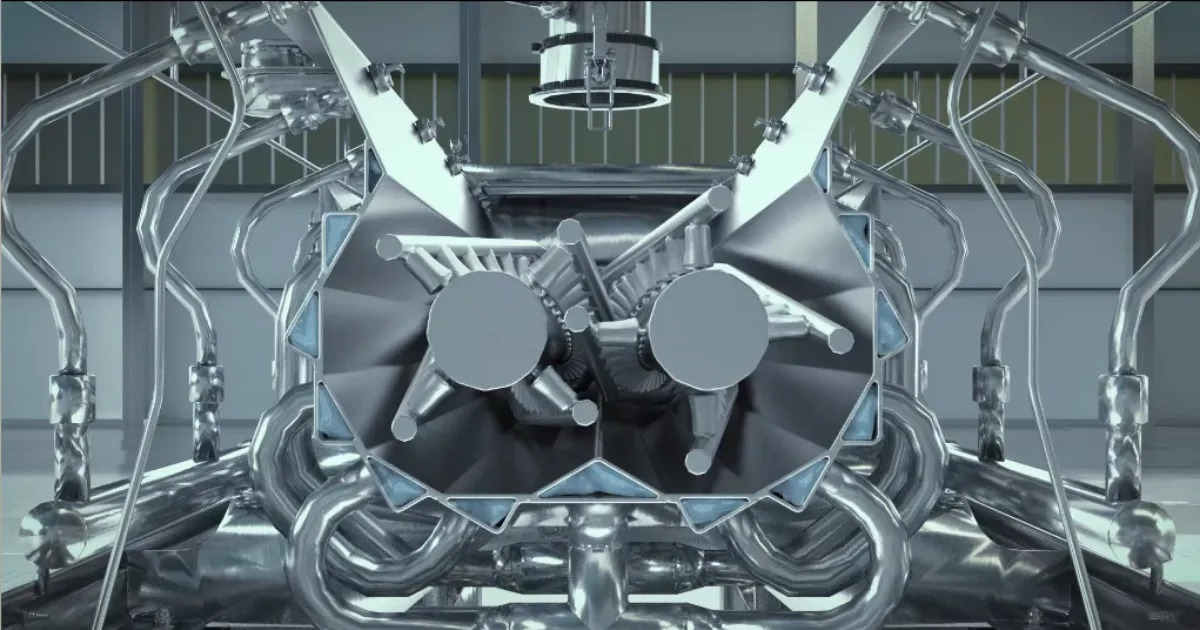

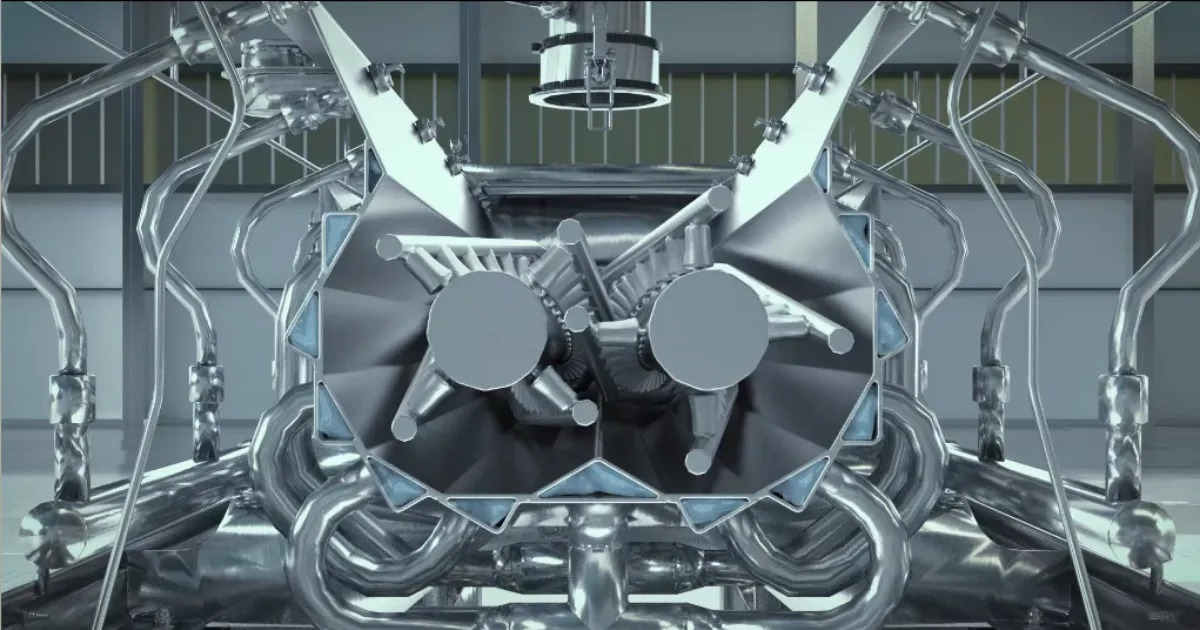

Continuous mixing is a fully automated process, including the continuous and precise weighing of both liquid and solid ingredients. In this system, ingredients are first combined in the homogenizer (phase 1) and then enter the continuous mixer (phase 2) as a pre-blended mixture. There, controlled mechanical energy is applied to develop the dough structure, with discharge occurring after a few minutes depending on the product requirements.

Because the entire process—from dosing to final dough—is automated, no manual intervention is required, ensuring that product quality is independent of operator influence and highly reproducible.

One of the most significant advantages of continuous mixing is the exceptional consistency it offers. Batch mixing, by contrast, can be prone to variations caused by inaccurate dosing, uneven hydration, or operator errors.

Additionally, batch production often involves downtime between cycles, during which dough must sit idle before further processing. Since dough is a dynamic, living product, this delay can lead to undesirable changes in temperature, density, and texture—commonly referred to as the "head and tail" effect of batch mixing.

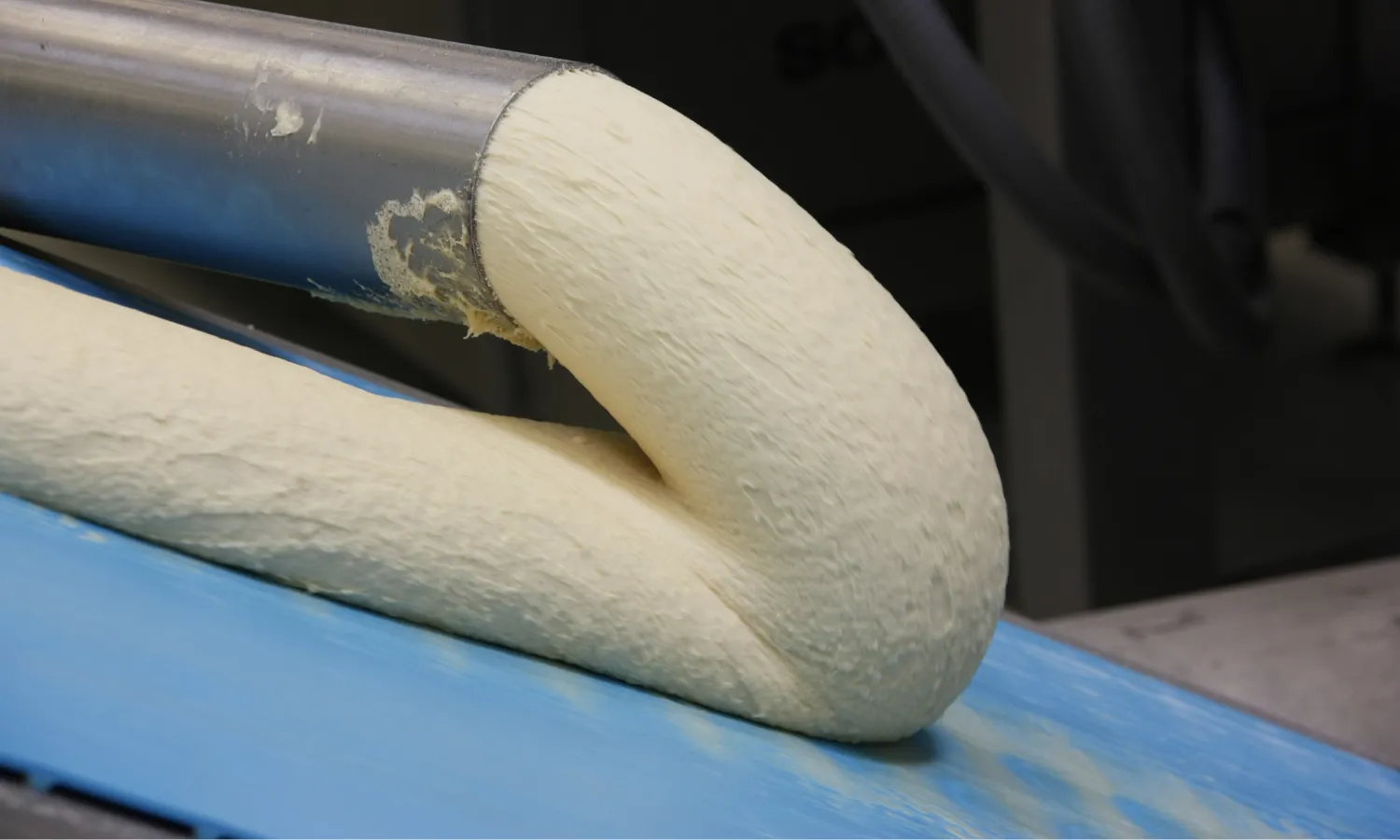

In a continuous system, every portion of dough is uniform in age and composition, and there’s no waiting time. This eliminates variation between cycles and ensures consistent weight, texture, and structure throughout production.

Tip: Consistency in dough quality also leads to more stable and efficient oven performance.

Continuous mixing systems offer precise and traceable ingredient control, thanks to fully automated dosing and real-time monitoring. The system captures and stores data on ingredient flow and dosing accuracy down to the second—critical for quality assurance and traceability.

Recipe changes are straightforward, and multiple formulations can be produced using a single system. Unlike batch mixers—where longer mixing times are used to influence dough development—continuous systems adjust mixing tool speeds (RPM), allowing for fine control and product flexibility on the same equipment.

While the initial investment for a continuous mixing system may be higher due to its automation level, the long-term operational savings are substantial. Benefits include:

Over time, these advantages result in a significantly lower cost of ownership compared to traditional batch mixing systems.

Batch mixers are inherently limited by their batch size and require downtime between cycles. Scaling production often means installing additional mixers, leading to increased floor space requirements and complexity.

Continuous mixers, on the other hand, offer high output capacity on a single unit, with systems capable of producing up to 10,000 kg of dough per hour. They can feed multiple production lines simultaneously, and as long as ingredients are supplied, the mixer continues to deliver a steady stream of dough.

This makes continuous mixing a space-efficient and scalable solution for growing production demands.

.webp)