What is dough homogeneity and how does Sobatech measure it?

.webp)

.webp)

At Sobatech, we specialize in producing highly homogeneous dough masses through advanced continuous mixing technology. But what exactly is dough homogeneity, and how do we measure it effectively?

Achieving a uniform dough texture is critical for consistent product quality in food and non-food production. In this article, we share insights from our testing facility and demonstrate several practical methods we use to assess dough homogeneity.

One simple yet effective way to visually asses dough homogeneity is by adding a few drops of liquid food coloring to the dough during trial runs. The evenness of color diffusion reveal how uniformly the ingredients are mixed. The more consistent the color throughout the dough, the better the mixing performance.

See below for images showcasing this test in practice

Another hands-on technique involves placing a small sample of dough between two oval glasses. By compressing the dough and holding it up to bright daylight, we can closely inspect its texture and identify any possible lumps or inconsistencies.

To demonstrate how mixing methods impact dough homogeneity, we conducted a simple yet telling experiment using a dough mixture made of water and powder premix. We subjected identical batches to three different mixing processes:

These results clearly demonstrate how shear intensity directly influences mixing quality.

See images below for reference

The experiment confirms a vital insight: the best blender is actually a kneader. To achieve optimal dough homogeneity, a sufficient amount of shear force must be applied. This is essential to disclose lumps, often casues by pieces of flour capsulized by liquid ingredients.

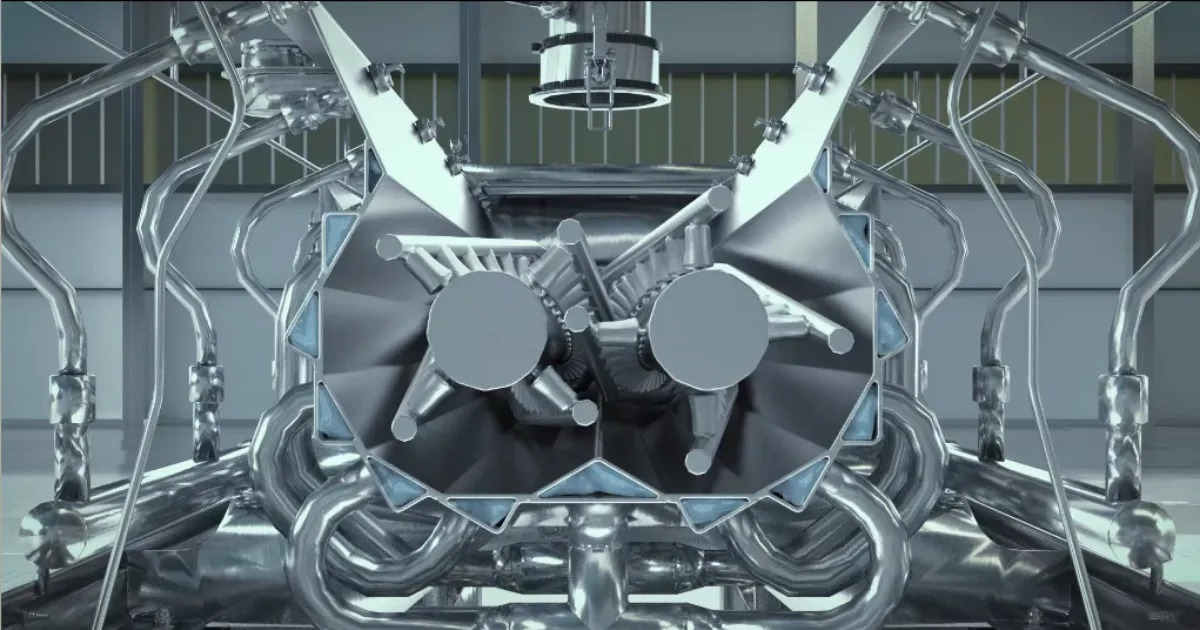

To adress this, Sobatech developed the wing-shaped high-shear mixing tool. This innovative design features an relatively high shear surface that applies controlled and intensive kneading, resulting in a smoother, more uniform dough mass without overworking the product.

Inconsistent dough can lead to product defects, baking inconsistencies, and inefficient production runs. By combining intelligent dosing and high-performance continuous mixing, Sobatech ensures that every batch meets the highest quality standards.

Contact Sobatech to explore how our continuous mixing systems can help you achieve perfect dough homogeneity at industrial scale.

%20(1).webp)