Frequently asked questions (FAQ) about continuous dough mixing

.webp)

.webp)

Are you considering upgrading your food production line with a continuous mixing system? Over recent months, we’ve compiled the most commonly asked questions from our customers about Sobatech’s continuous dough mixing technology. Below, we provide clear and concise answers to help you better understand the capabilities, benefits, and features of our solution.

Sobatech's continuous mixers are available in a wide range of capacities. Our smallest system produces approximately 100 kg of dough per hour, while our largest configuration can exceed 10,000 kg per hour. We also offer tailored solutions to match specific production requirements between these two ends.

Our systems continuously monitor the Specific Mechanical Energy (SME) — the mechanical energy applied to the dough, expressed in Wh/kg. SME provides a real-time, objective indicator of dough development and quality.

For instance, if ingredient temperatures rise due to seasonal fluctuations, the dough's viscosity may decrease. A lower viscosity leads to reduced resistance, which in turn results in a lower SME value. By constantly tracking this parameter, the system ensures consistent dough quality, regardless of external influences.

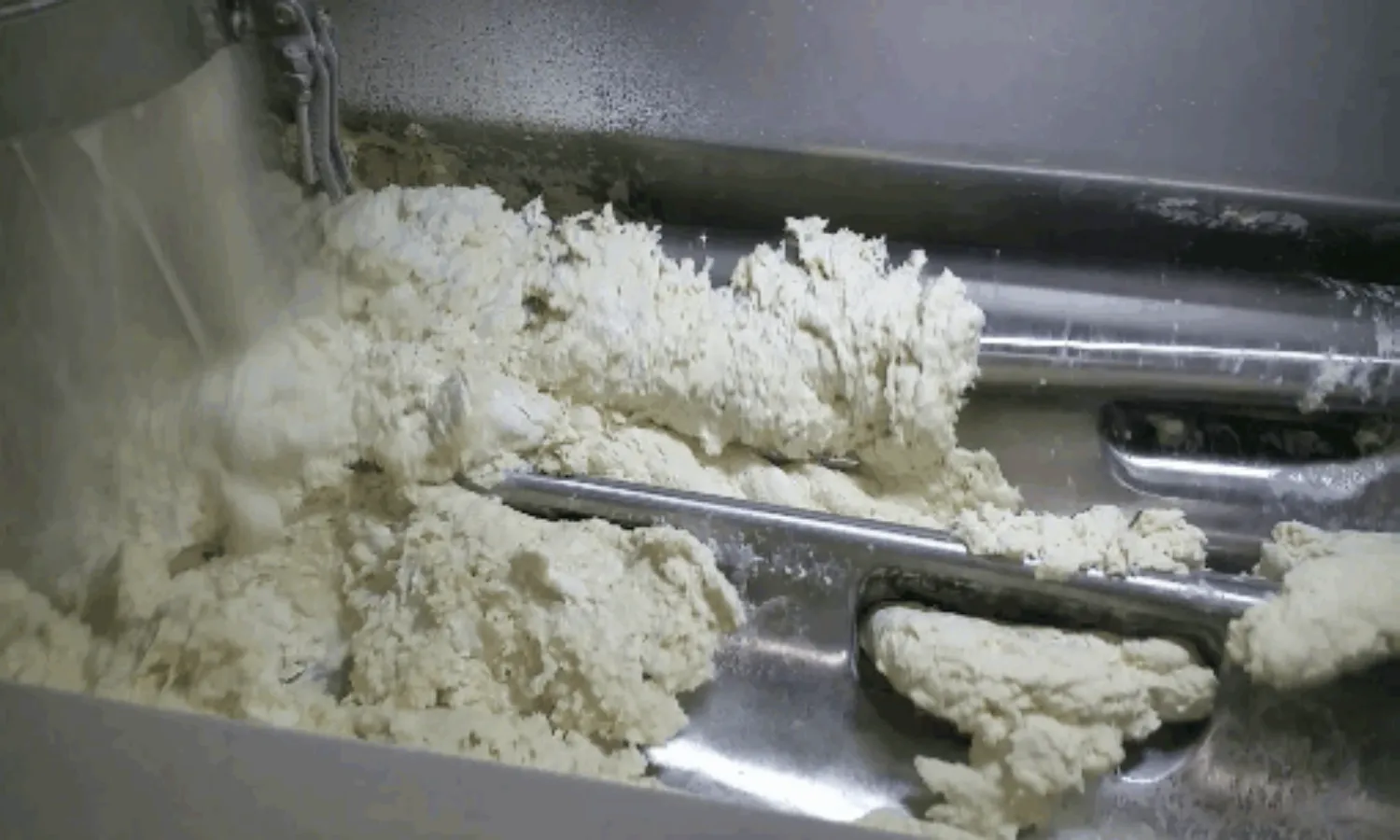

Continuous mixing delivers improved dough consistency, increased throughput, and lower operational costs. Unlike batch mixing—where dough ages and characteristics vary between batches—continuous mixing ensures each dough portion is identical in age and quality when entering the next process step.

Moreover, continuous systems are fully automated, making product results independent of operator expertise.

Any product traditionally produced on a batch mixer can also be manufactured using a continuous system. Sobatech’s continuous mixing solutions support a broad range of applications. Click here to explore our application page.

Yes. In batch mixing, product variations are typically achieved by adjusting mixing time. In continuous mixing, this is done by modifying the RPM (shaft speed) of the mixing tools. This allows for high flexibility within a single system.

The cost of a continuous mixer is sometimes misunderstood due to improper comparisons with batch mixers. A complete continuous mixing system includes automated ingredient dosing (both solids and liquids), while batch systems are often priced without the dosing.

Although the initial investment may be higher, continuous systems offer significant long-term savings due to:

The result is a lower total cost of ownership and quicker return on investment. For a customized cost-benefit analysis, please contact us.

Dough temperature is primarily controlled through the temperature of process water. For more precise requirements, Sobatech offers double-jacketed mixing chambers for heating or cooling. For extreme temperature applications, our HOT & COOL technology provides an ideal solution.

Sobatech’s mixers feature a fully automated Clean-in-Place (CIP) system, which allows for fast, efficient, and hygienic cleaning—without manual intervention. See how our CIP system works.

Recipe changeovers depend on the similarity between formulations:

Read more about continuous recipe flexibility in this news item.

Sobatech systems include gravimetric dosing solutions, the most accurate feeding technology available. Our loss-in-weight feeders are engineered to deliver dosing accuracies within 1%. The system continuously monitors all ingredient streams and logs real-time data, guaranteeing recipe fidelity throughout production.

The mixer produces a continuous stream of dough, eliminating the need for batch resizing equipment. This output can be fed directly into the dough make-up line, ensuring seamless integration with downstream processes.

In continuous mixing, throughput is determined by the ingredient feed rate, not mixing time. Mixing intensity—traditionally managed by time in batch systems—is instead controlled by adjusting the RPM of the mixing tools.

This separation of throughput and intensity allows for more precise control. In contrast, increasing mixing time in batch systems inherently reduces throughput.

Sobatech’s continuous mixing solutions deliver consistent quality, improved process efficiency, and significant labor savings across a wide range of food applications.

Have more questions or need a tailored consultation?

Reach out to our team—we’re happy to help you explore your options.

.webp)