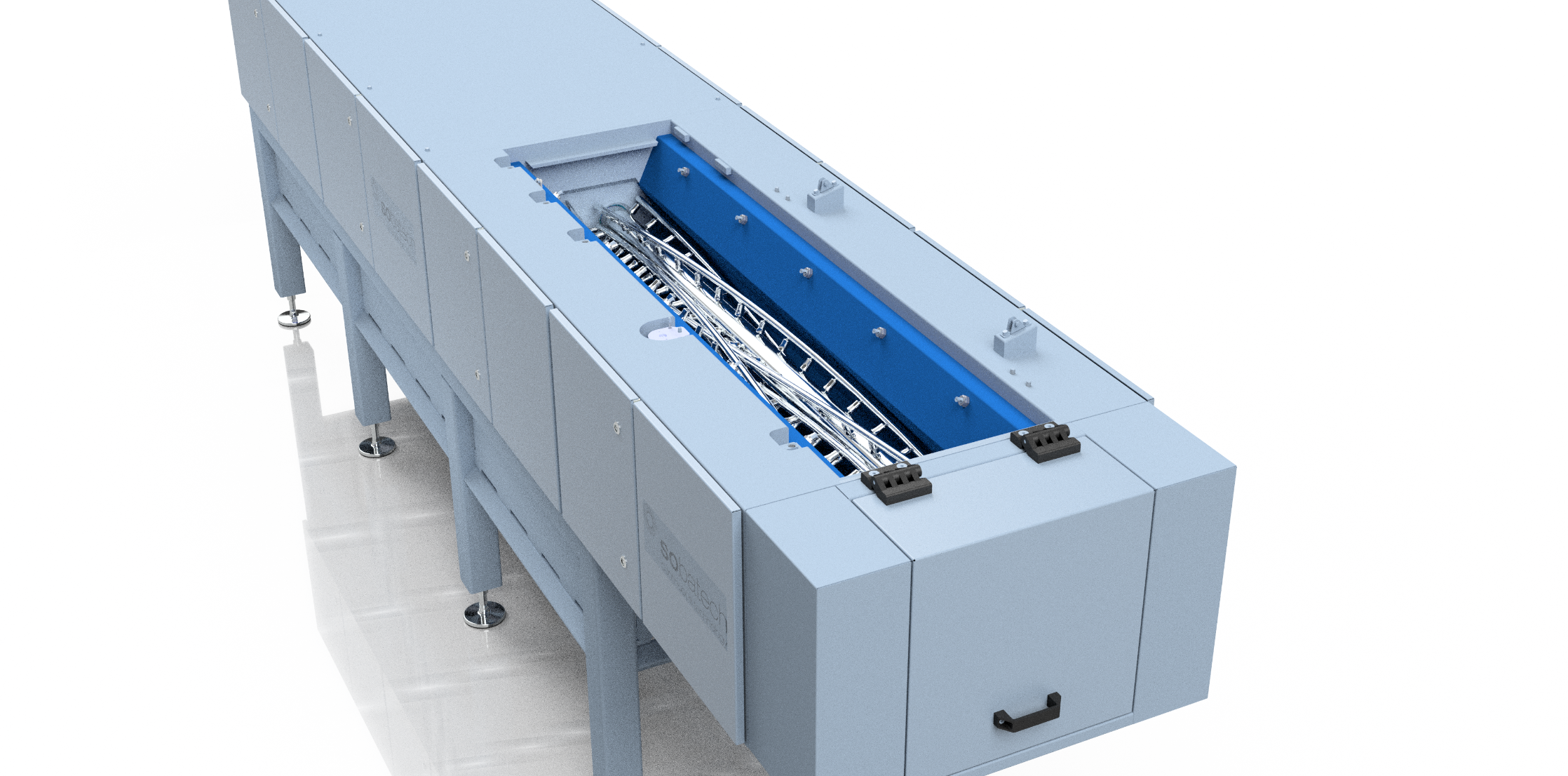

The continuous mixer

PHASE 2 MIXING

The Sobatech continuous mixing system consist out of two mixing phases. First of all, the ingredients are evenly and accurately distributed over the complete mass (phase 1 mixing). After that, controlled mechanical energy is applied to the blend of ingredients (phase 2 mixing).

PHASE 1 MIXING: THE HOMOGENIZER

After dosing, the powder ingredients fall from the weighing system through the homogenizer into the continuous mixer. Whilst falling through the homogenizer, the powders are injected by the liquid ingredients. The liquids are injected in a pre-defined order and by means of medium pressure. This non-mechanical way of blending ensures an even distribution of the raw materials and guarantees a high level of water absorption.

PHASE 2 MIXING: THE CONTINUOUS MIXER

After the homogenizer, the blend of ingredients enter the actual continuous mixer. In this second phase of mixing, controlled mechanical energy is applied to correctly develop the product. The contra-rotating mixing tools of the continuous dough mixer are responsible for the controlled flow of product throughout the mixer. The Sobatech continuous mixer is known to be very effective due to their high product-tooling ratio. This refers to the relatively little amount of product in the mixing chamber with an high volume of mixer tooling. As a result, a large part of the energy developed by the mixer tooling is put into the product.

Both the homogenizer (phase 1 mixing) and the continuous mixer (phase 2 mixing) operate based on the first in/first out principle.

Product specification

PRODUCTION VOLUMES

Sobatech continuous mixers can produce 50 up to 10.000 kg of dough per hour. This can be accomplished in an employee free operational environment resulting in significant (labor) cost savings.

SENSITIVE INGREDIENTS

The mixing tools of the continuous mixer handle the raw materials gently and efficiently. Sensitive ingredients such as fruit, flakes, nuts or raisons can be introduced without degrading.

CLOSED SYSTEM

The Sobatech continuous mixing system is a closed system. This means that there is no pollution from outside of the machine. Also, food safety is optimized by ensuring dough is never exposed to the environment. Cleaning the area around the continuous mixer is also much easier because there is less creation of dust.

SAFETY SWITCHES

There are double safety switches mounted in the top covers of the continuous mixer to ensure that the tools stop turning immediately after opening. Also, a signal is given to the PLC so that part of the line stops normally. Lastly, a sound signal goes off to warn the operator.

LESS ENERGY LOSS

Sobatech’s continuous dough mixers are able to carry out the mixing process in defined and controlled steps. As the continuous mixer is able to bring in high energy levels in a very short amount of time, the so-called time to peak point (the point where the gluten are developed the strongest) is reached faster.

TEMPERATURE CONTROL

Generally, temperature is controlled by means of the process water. Also, the continuous mixing system can be equipped with a double jackets. This is an extremely efficient way of maintaining the right dough temperature as a continuous mixer provides a relatively large contact surface. Lastly, for extreme product temperatures, the HOT&COOL technology can be used.

CLEANING IN PLACE (CIP)

Sobatech continuous mixing systems can be equipped with an automatic cleaning in place system.