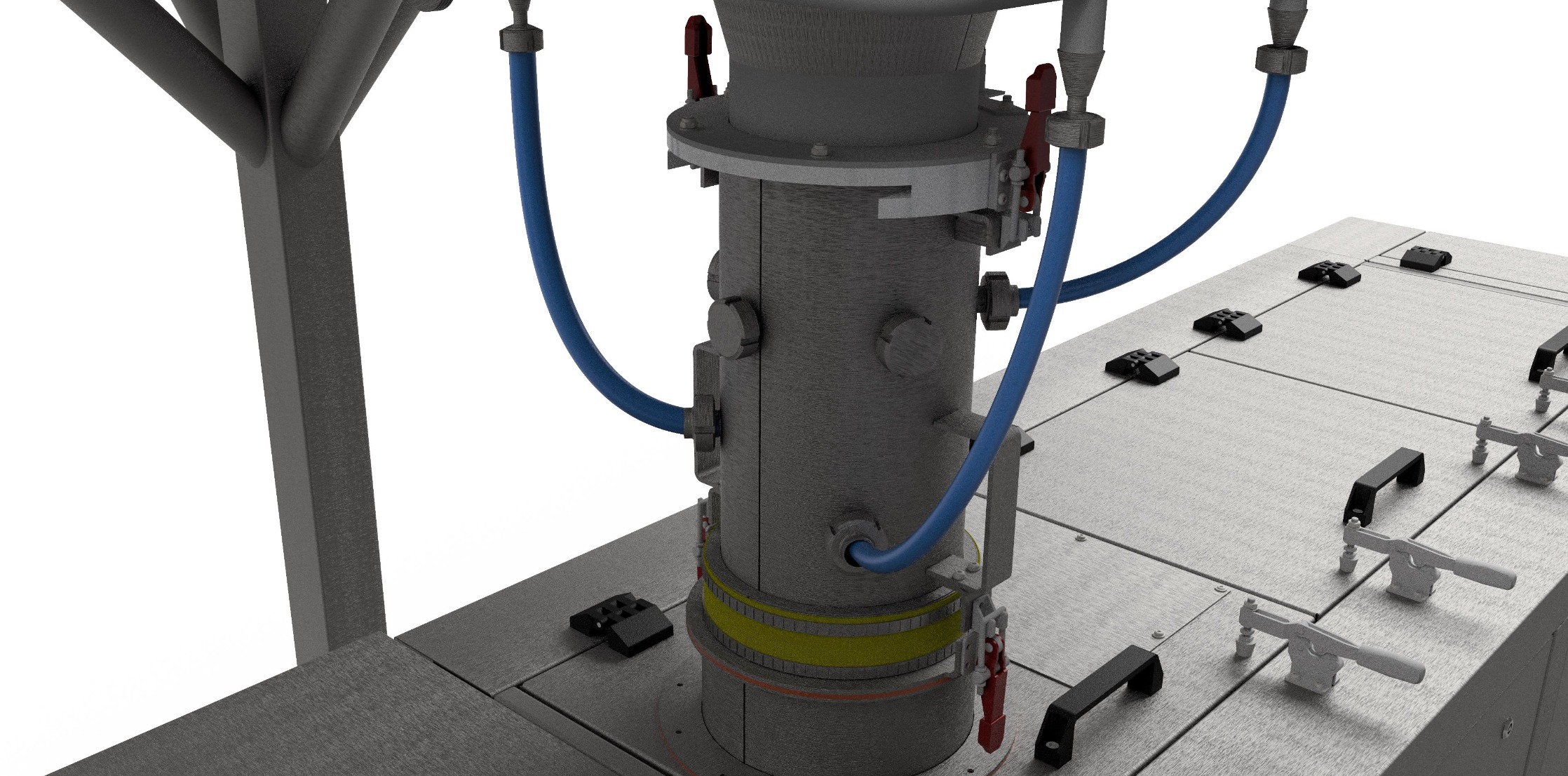

The homogenizer

Phase 1 mixing

The homogenizer is a tube shaped device responsible for injecting the liquid ingredients, by means of medium pressure, into the powder ingredients like flour and premix. Sobatech’s continuous mixing system consists out of a 2-phase process for mixing the ingredients into a consistent and homogeneous mass. After being gravimetrically dosed, and on their way to the continuous mixer inlet, the ingredients pass through the homogenizer phase (phase 1 mixing).

The homogenizer consists out of different entry levels meaning that each liquid enters the homogenizer in a pre-defined order. The low viscosity liquids enter higher compared to the medium or high viscosity ingredients. Because of the relatively large contact area of the dry ingredients with the liquid ingredients; a very high (water) absorption is enabled.

This first phase of mixing is a non-mechanical way of blending the ingredients before controlled mechanical energy is applied to the product in the actual continuous mixer (phase 2 mixing).

Product specification

- Seperate connection point for each liquid

- Possibility to inject at different levels within the homogenizer

- Liquids enter the mixer in a pre-defined order

- Dedicated nozzles with spray pattern for all liquid ingredients

- Fast & easy connection/dis-connection function (ensuring easy cleaning procedure)

- Complete stainless steel execution