Plant-based meat

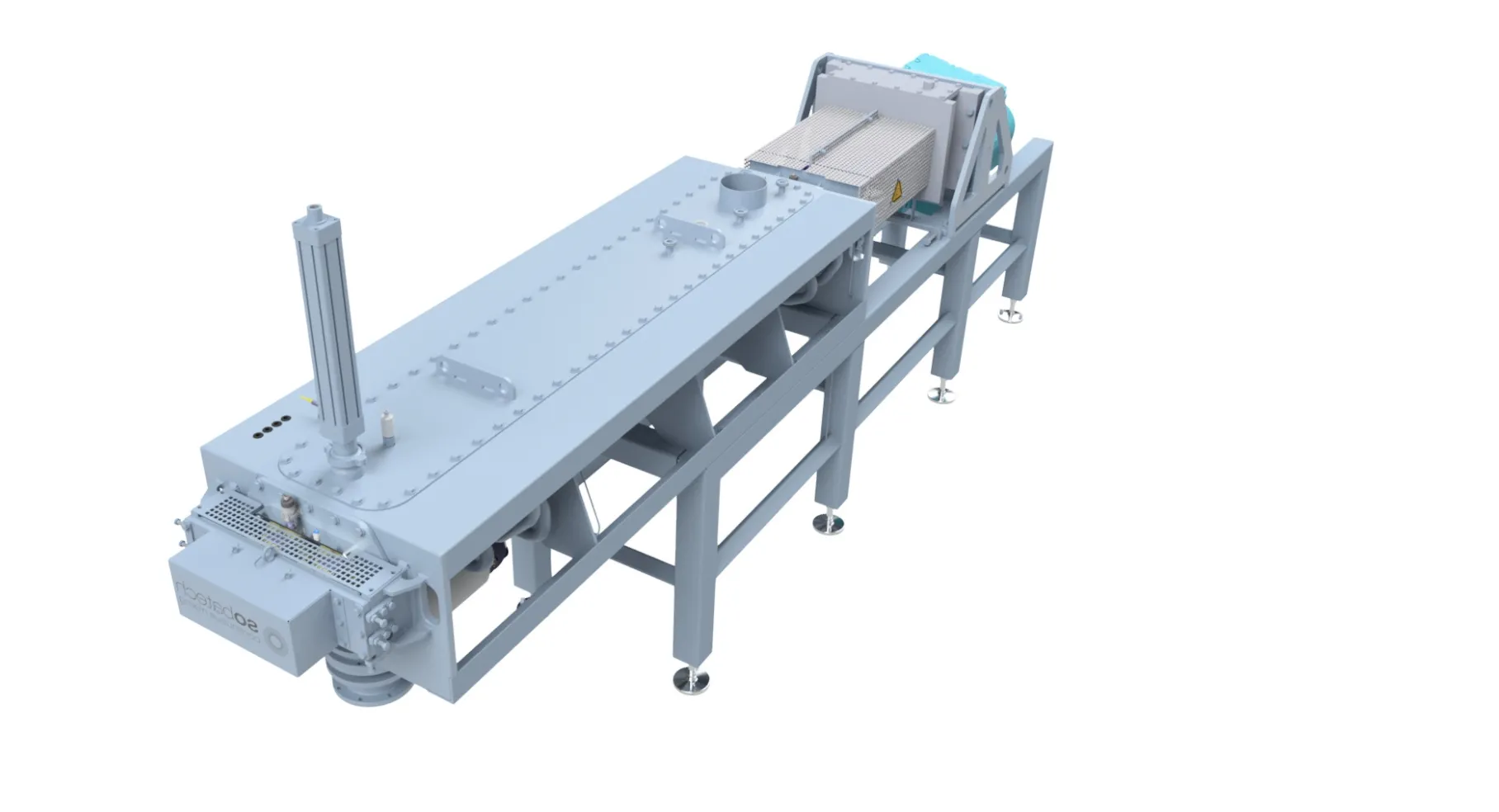

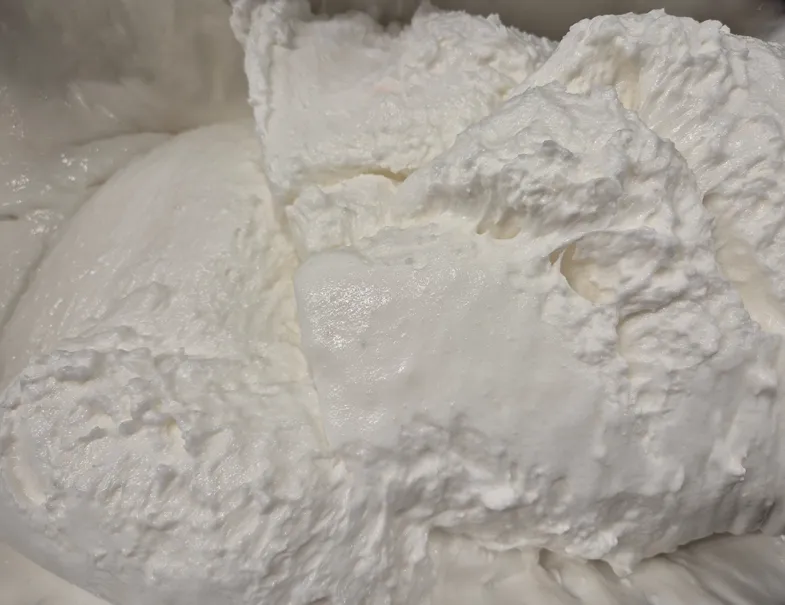

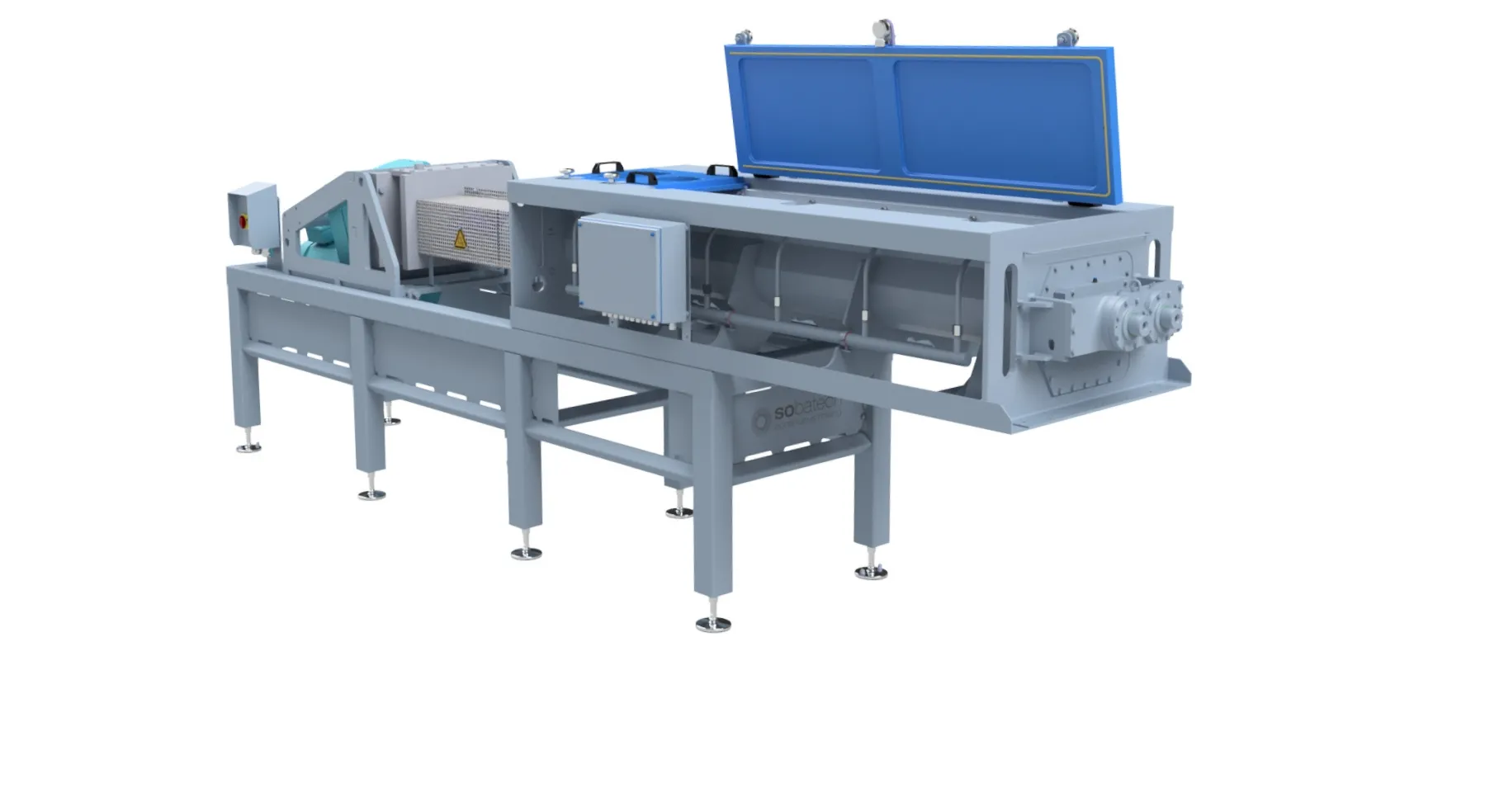

Plant-based meat is a category of food products engineered to replicate the taste, texture, and nutritional profile of conventional meat. To support the growing global demand for meat alternatives, Sobatech has developed a fully continuous, three-phase process specifically for producing Texturized Vegetable Proteins (TVP)-based products, enabling efficient and scalable production. The system is also compatible with other plant-based formats, such as High Moisture Extrusion (HME) pieces. Each phase of the process requires distinct shear and kneading conditions. To optimize performance, Sobatech mechanically decouples the phases, ensuring precise shear management and overall process efficiency. The fully automated system guarantees consistent and uniform blending of all components, eliminating the need for manual intervention. Each phase can be purchased as a standalone module, offering flexibility for producers with specific process needs.

%20hydrater%20(4).webp)