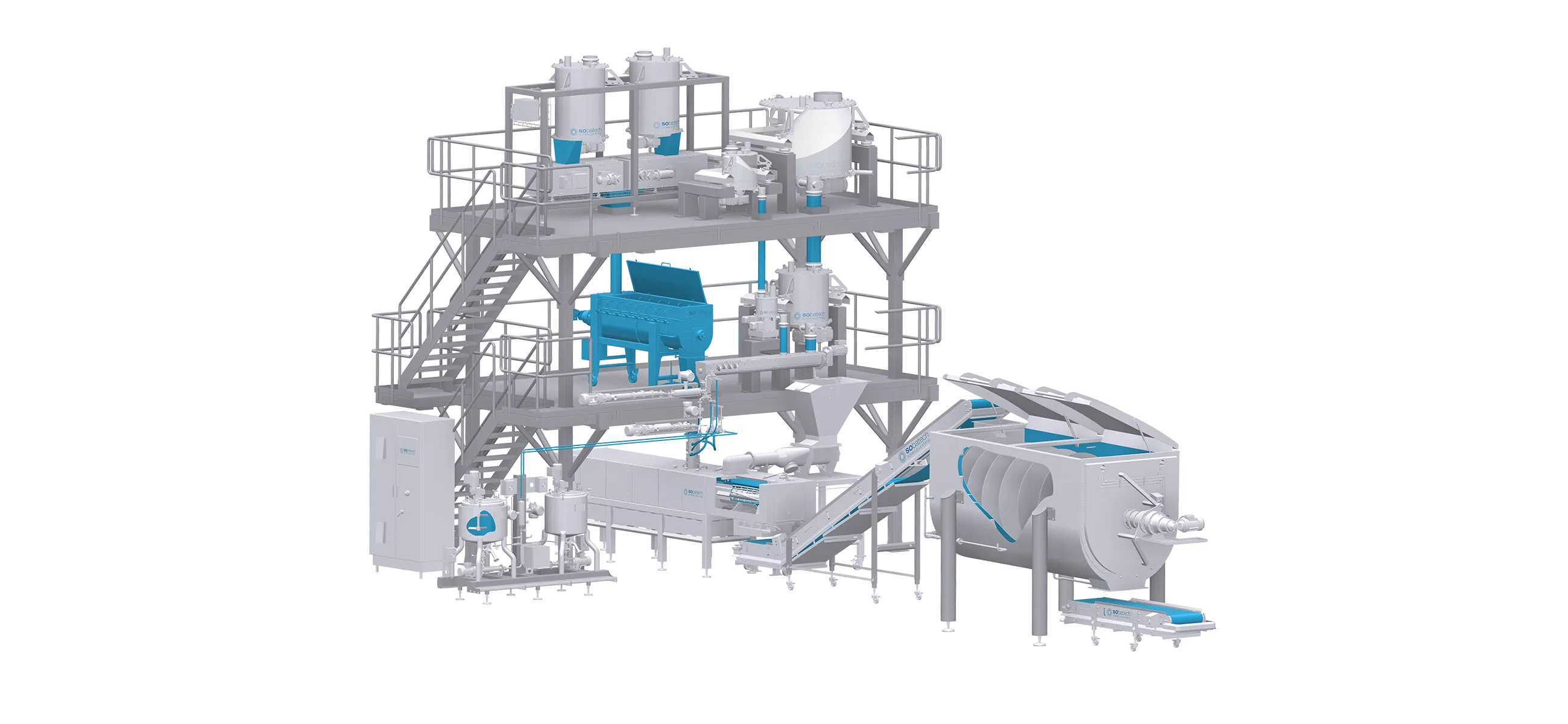

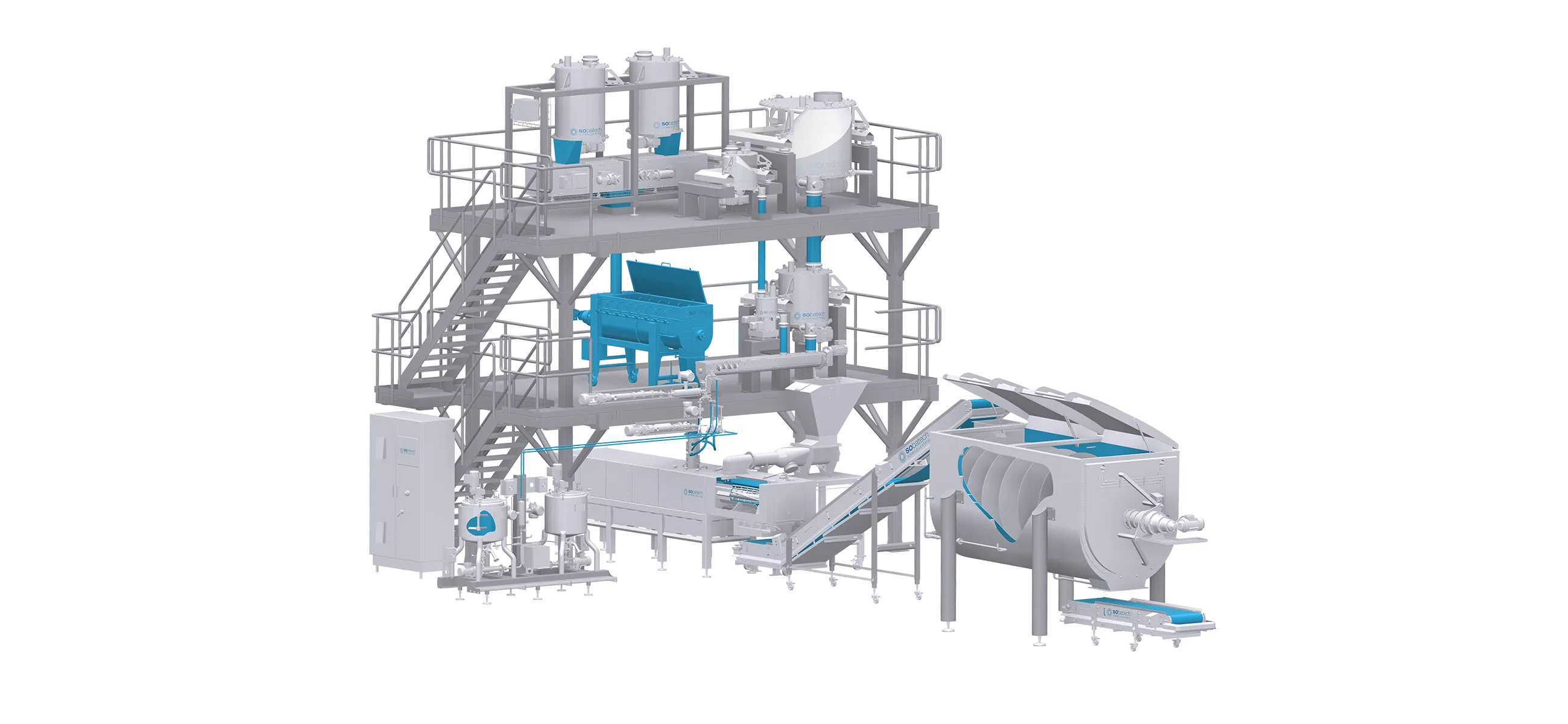

Click and discover: interactive journey through our continuous mixing solutions

Explore the future of industrial mixing

Click and discover: interactive journey through our continuous mixing solutions

.webp)

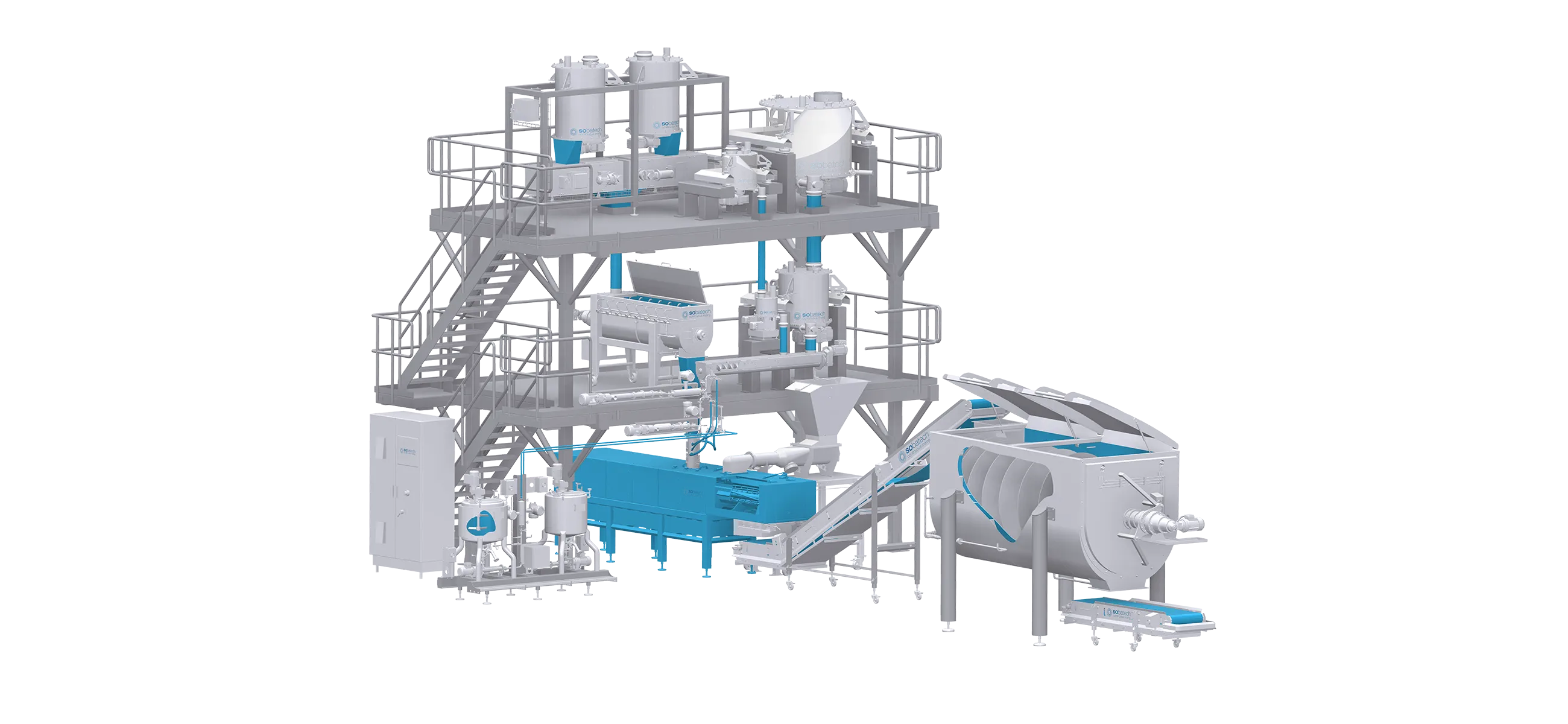

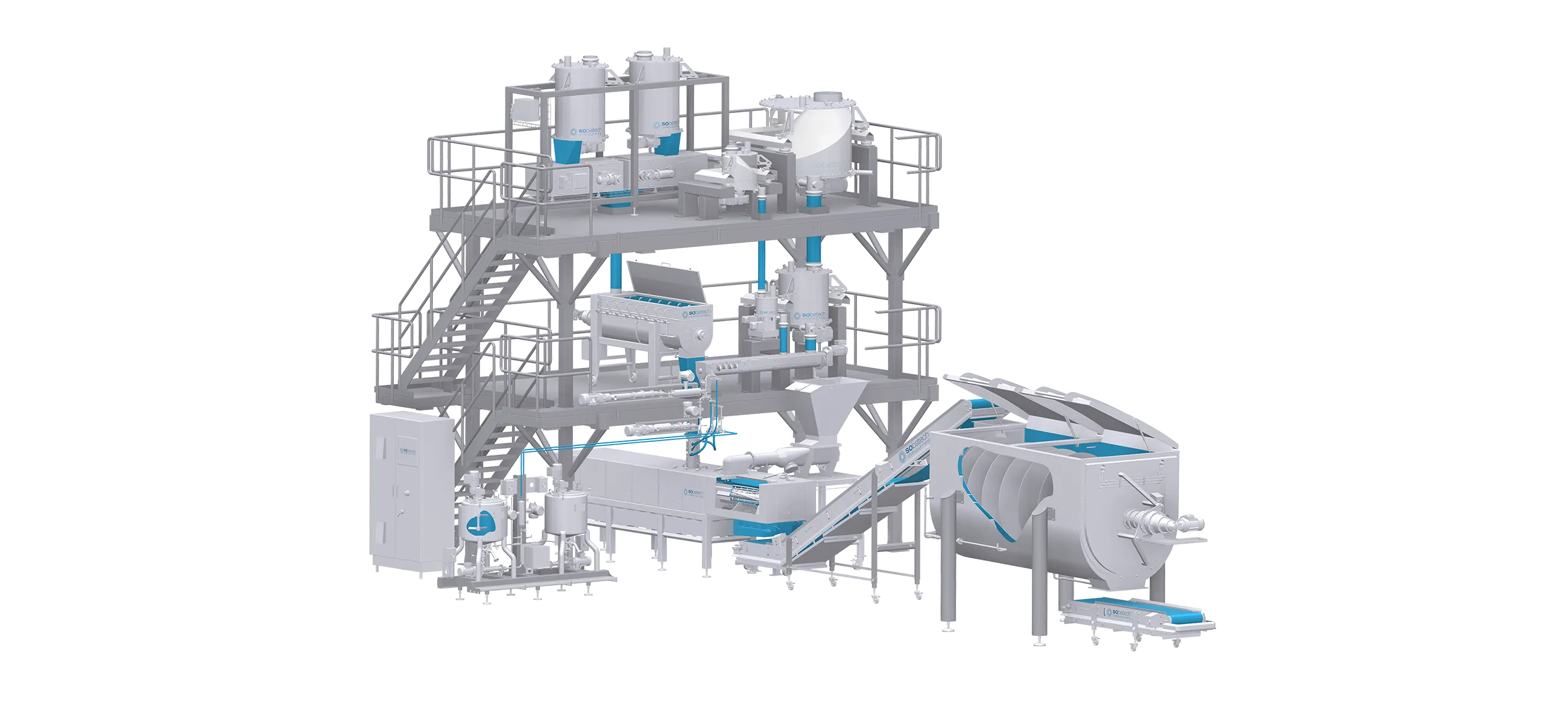

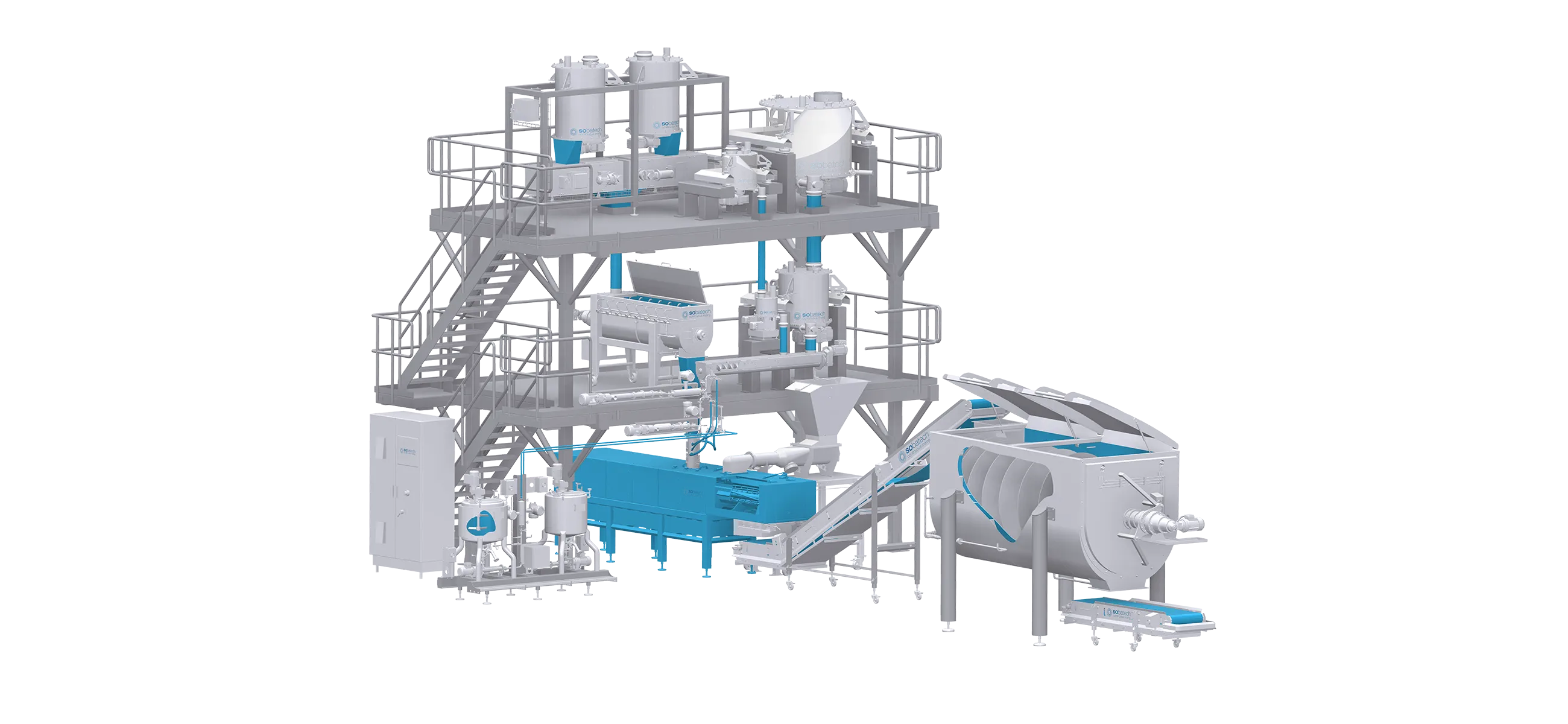

Experience the efficiency and precision of the Sobatech continuous mixer, designed for consistent high-quality dough production. The two-stage mixing process ensures optimal mixing of ingredients, resulting in consistent product quality.

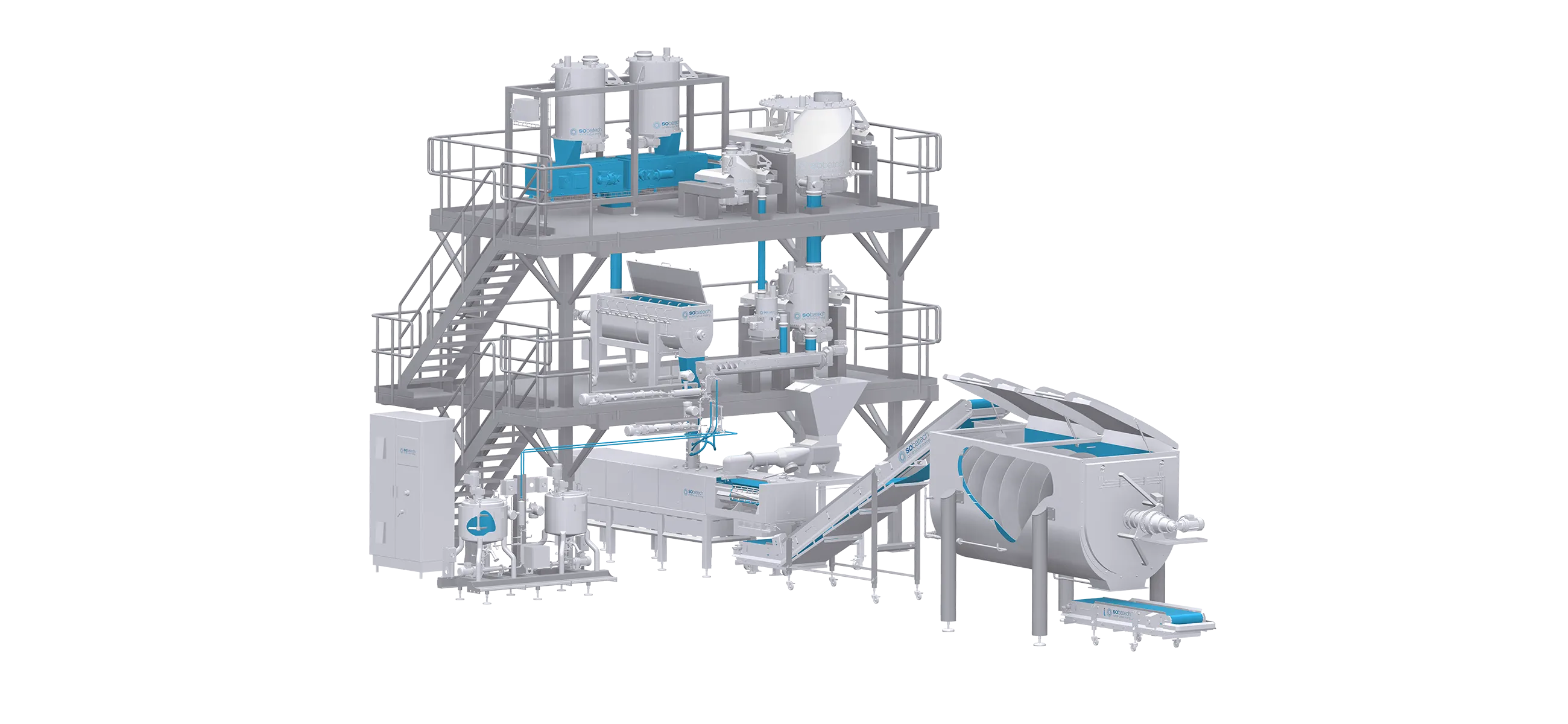

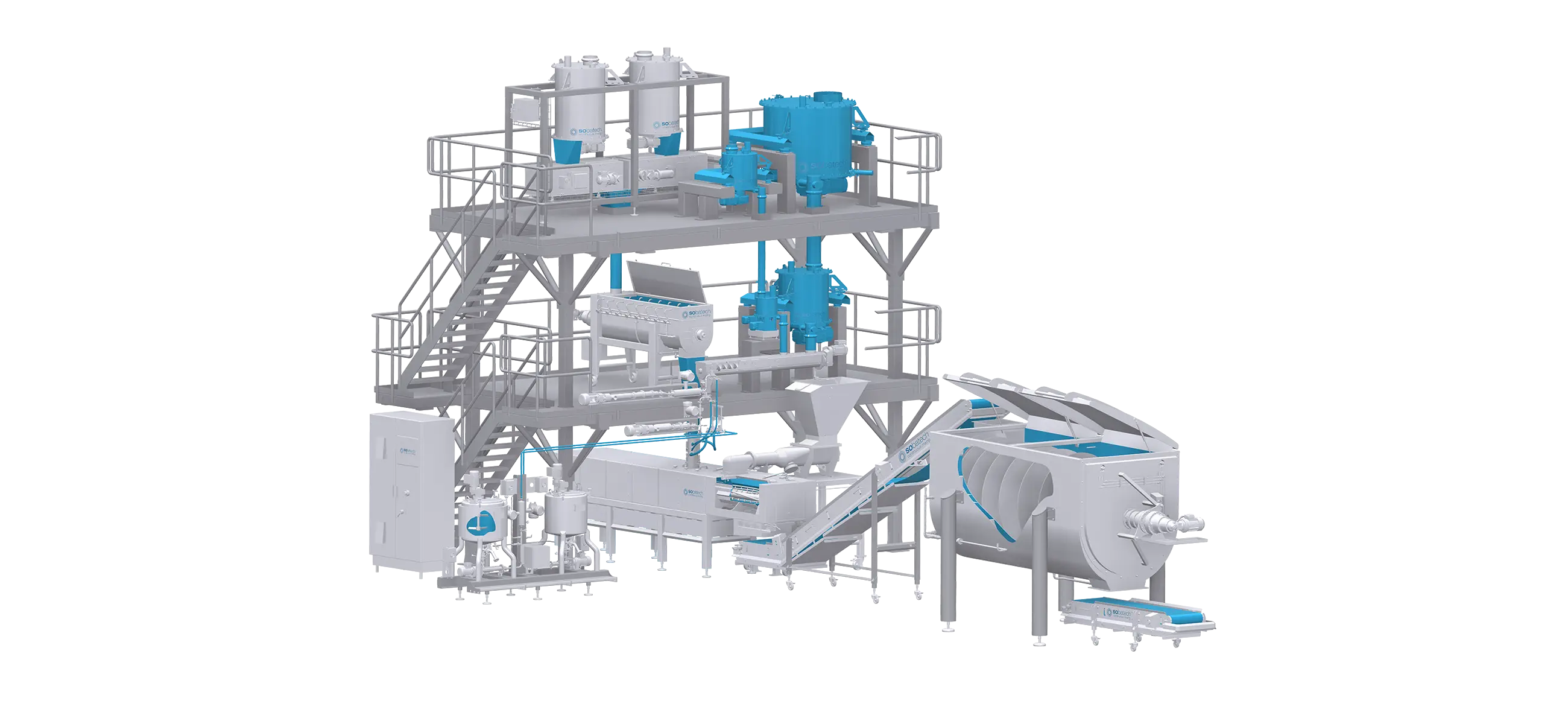

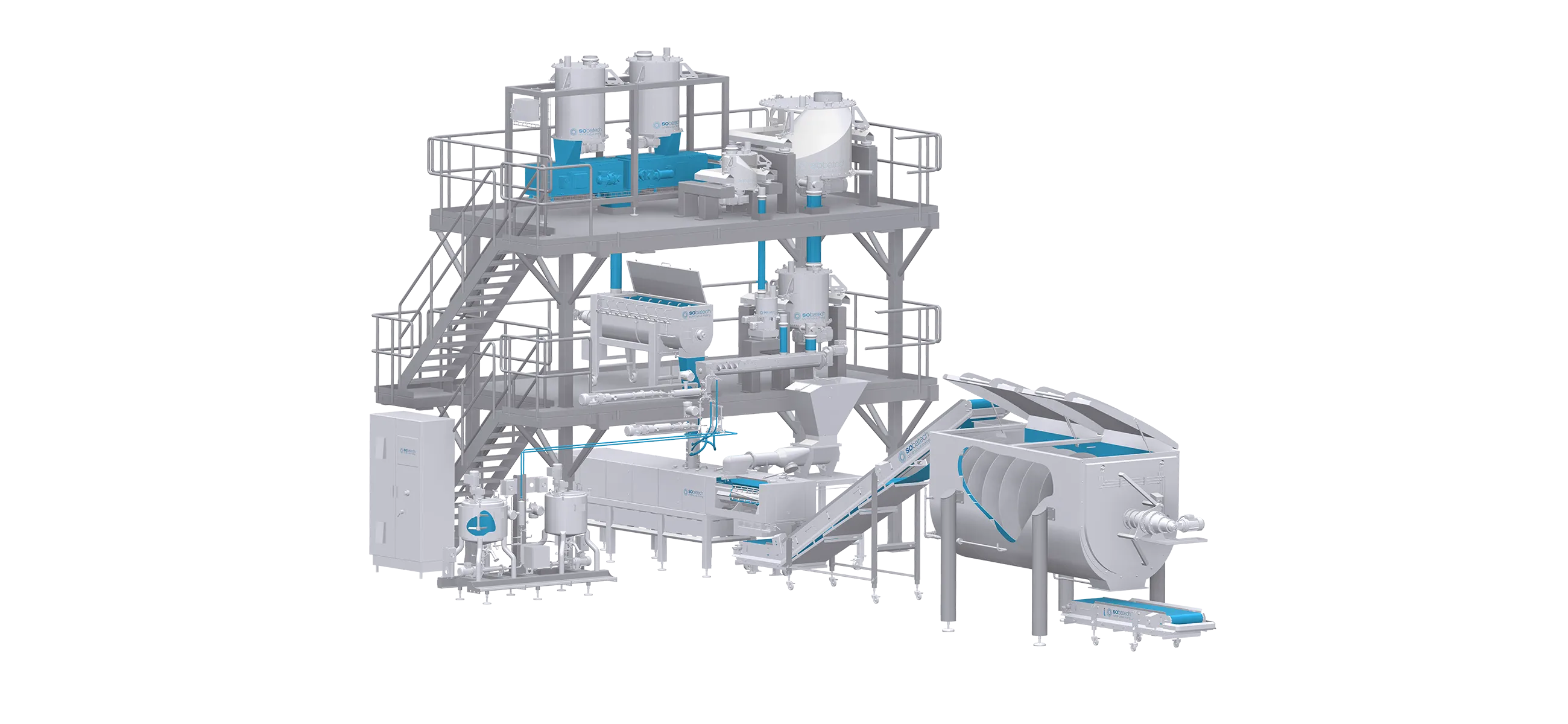

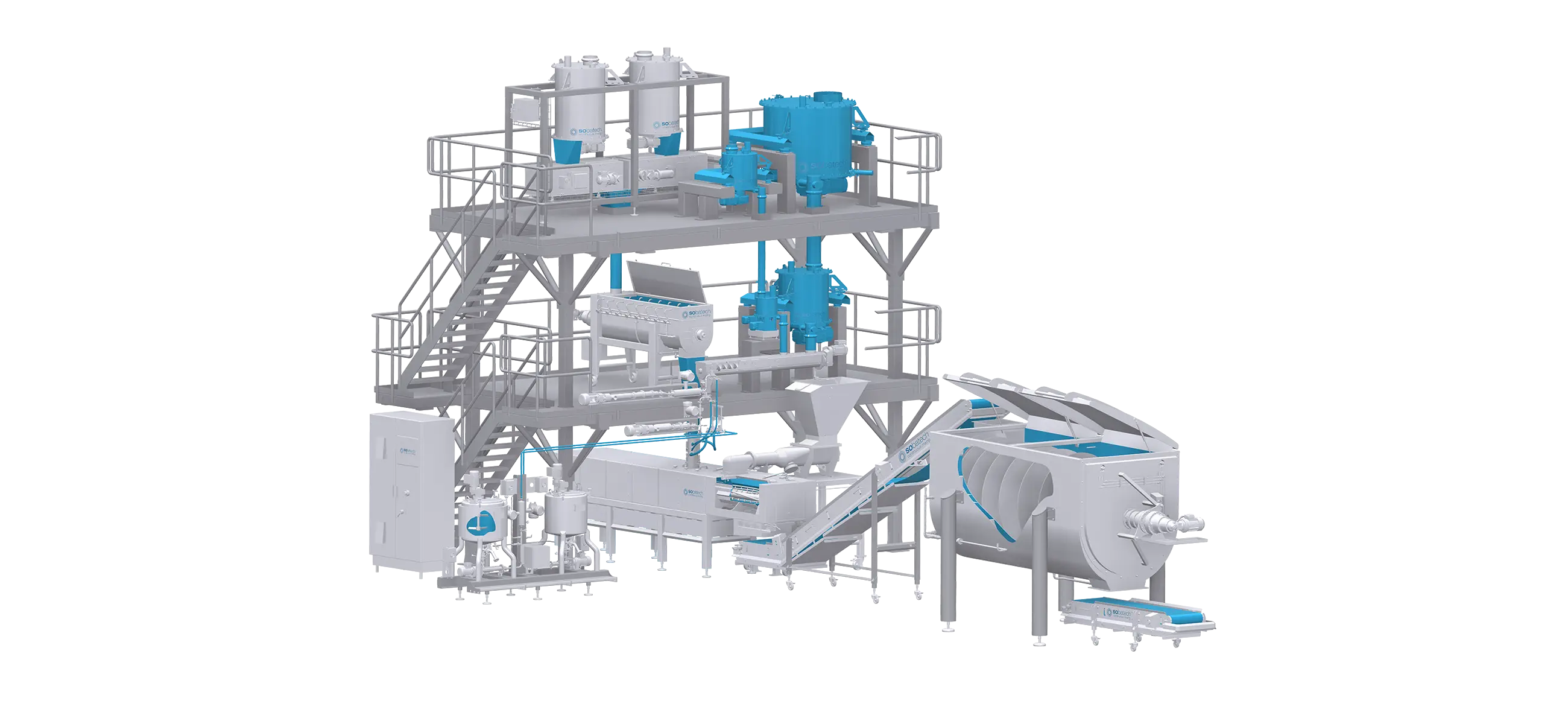

A gravimetric weighing belt precisely controls the flow of materials with continuous weighing, offering efficient dosing from 20 to 4,000 kg per hour. Making it ideal for both large quantities and sensitive ingredients.

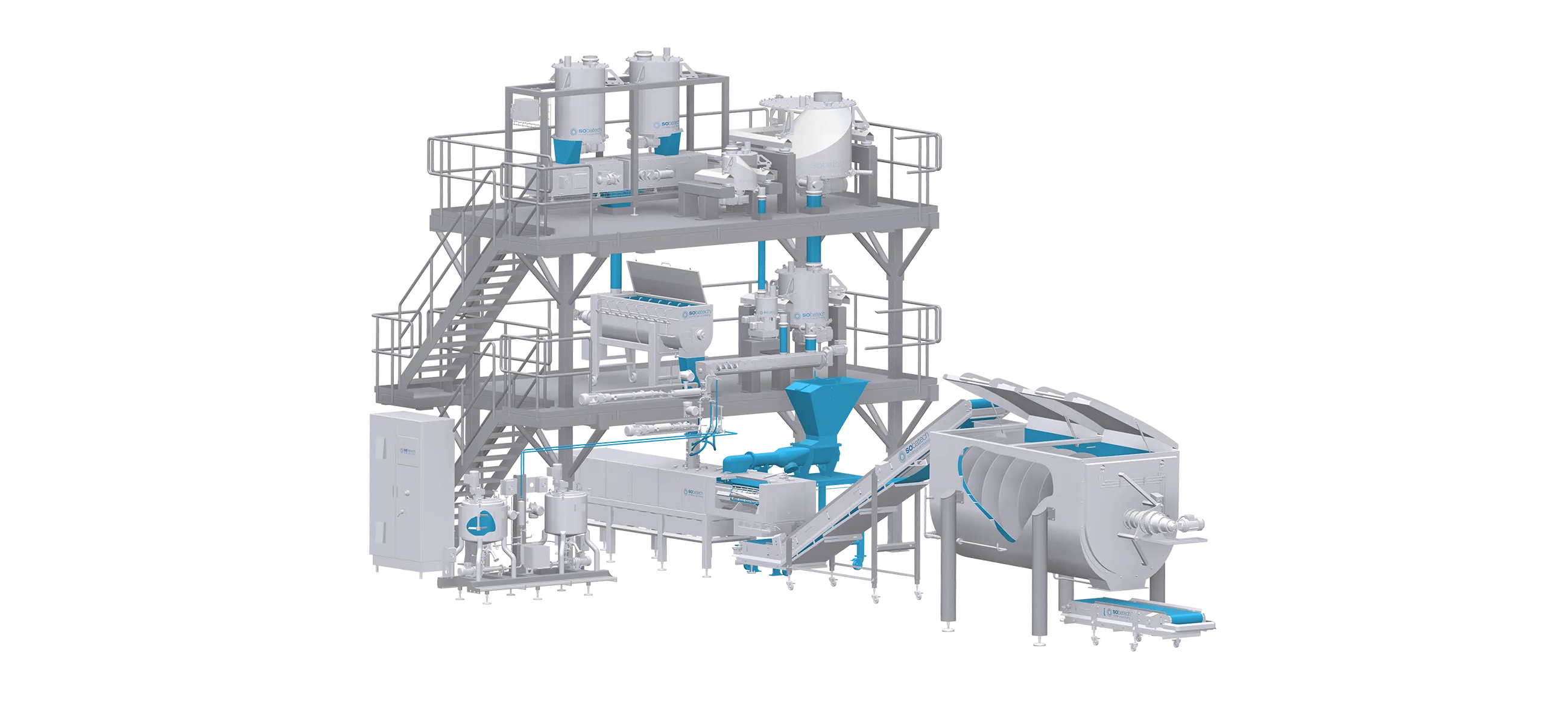

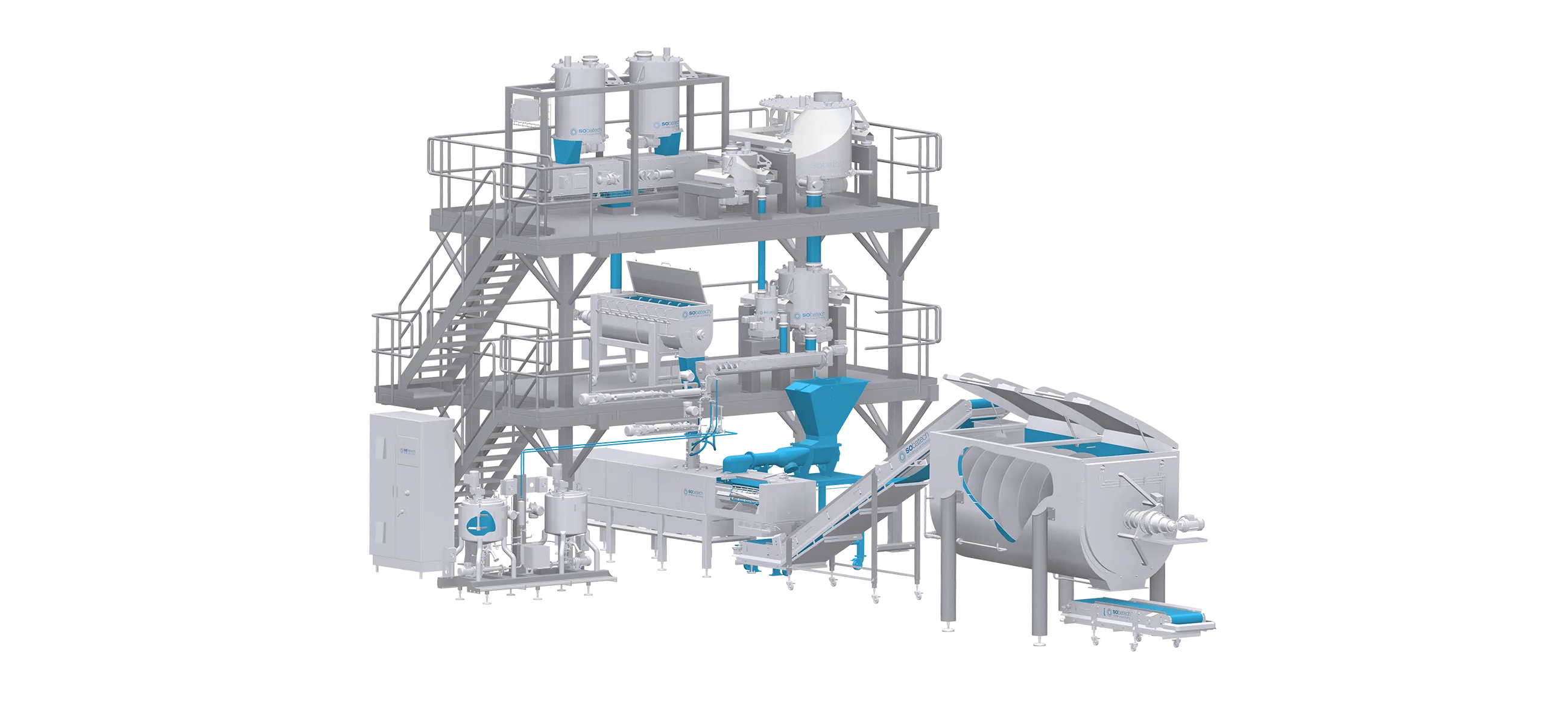

Rework involves reintroducing dough from the sheeting line back into the final mixing stage, ensuring recipe consistency. This carefully controlled step helps optimize ingredient use.

.webp)

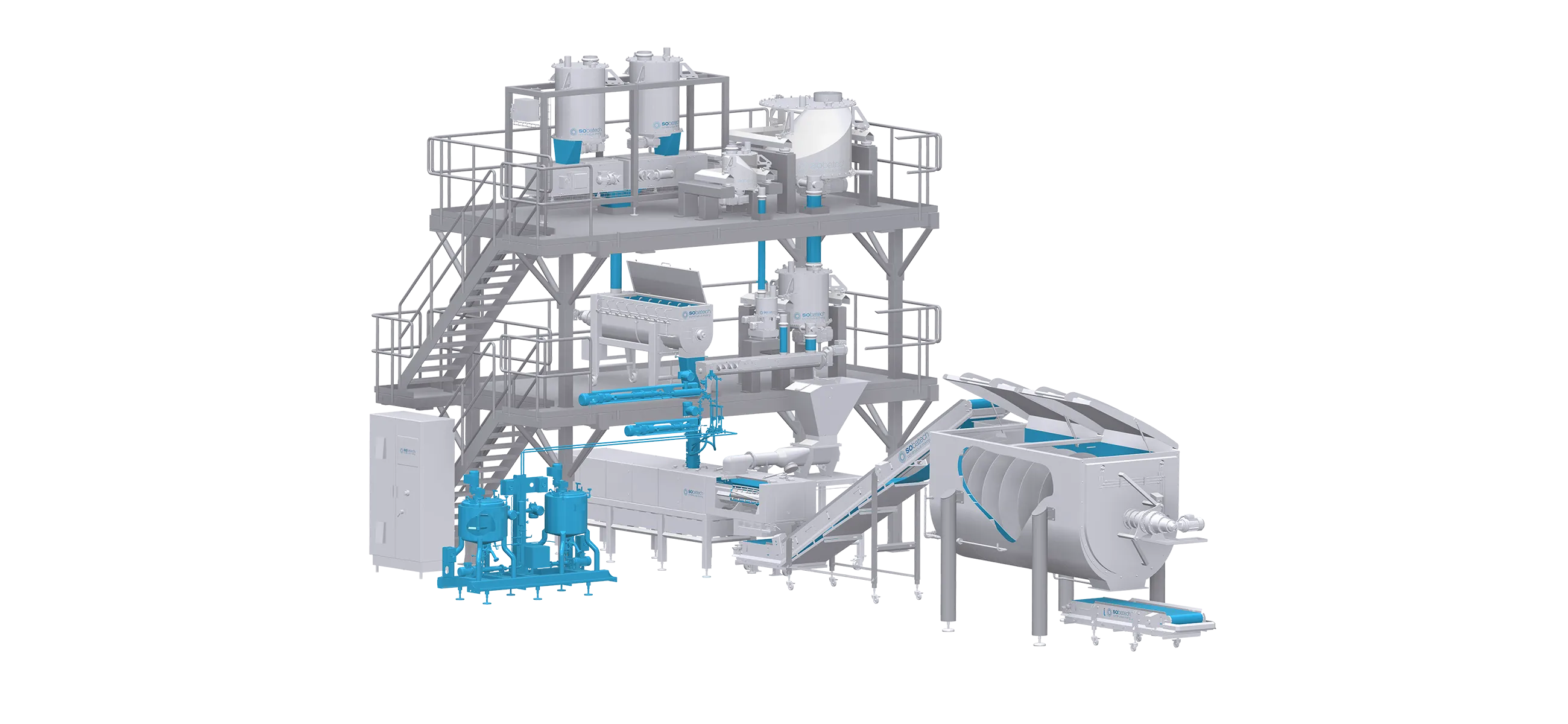

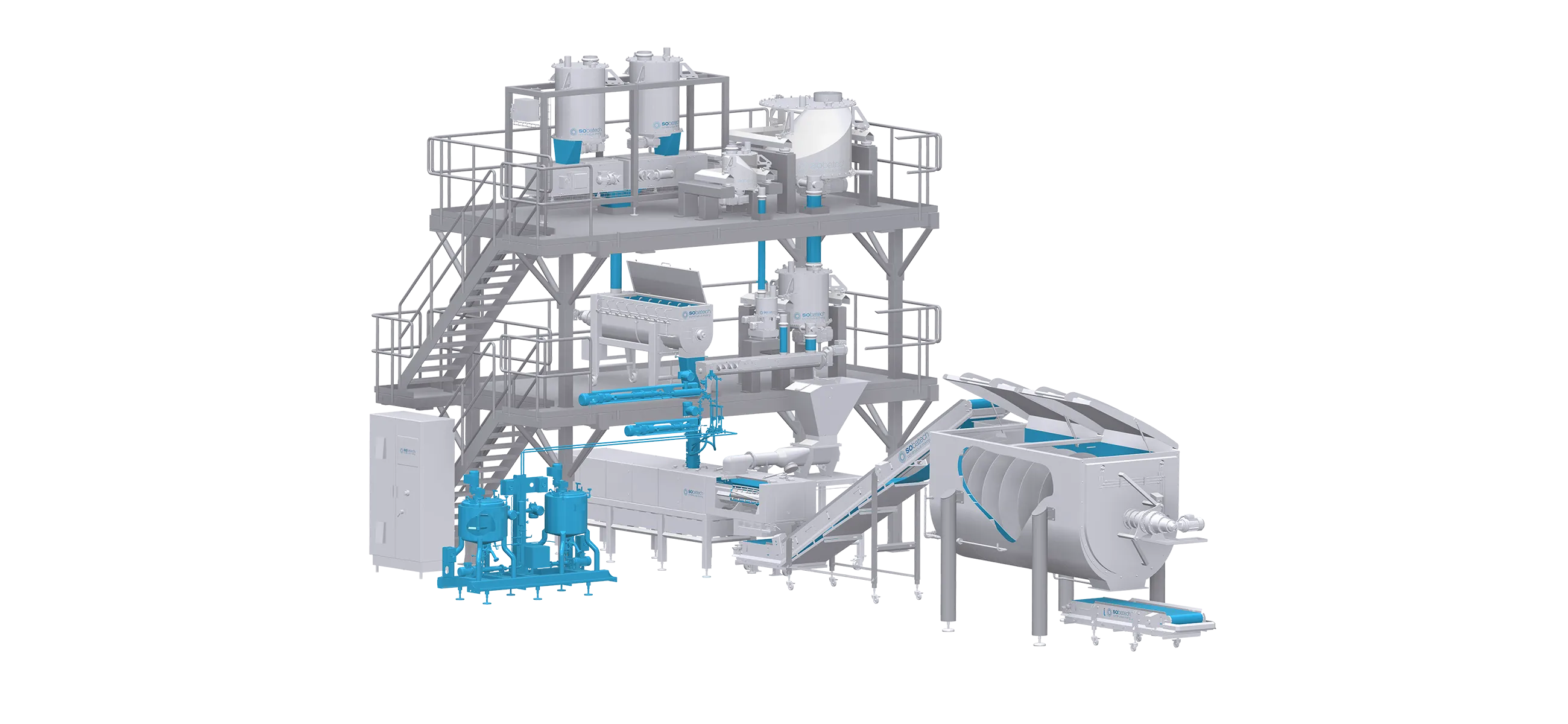

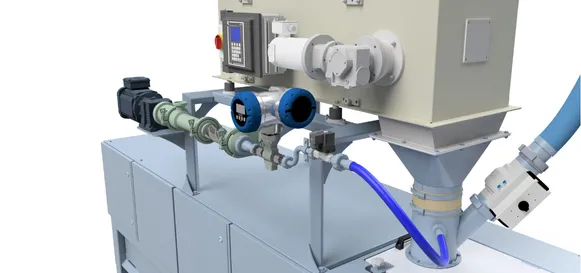

Sobatech uses advanced measuring equipment to accurately dose liquid ingredients. With advanced technologies such as Magflow and Coriolis flowmeters, we guarantee precise dosing for optimal product quality.

%20hydrater%20(1).webp)

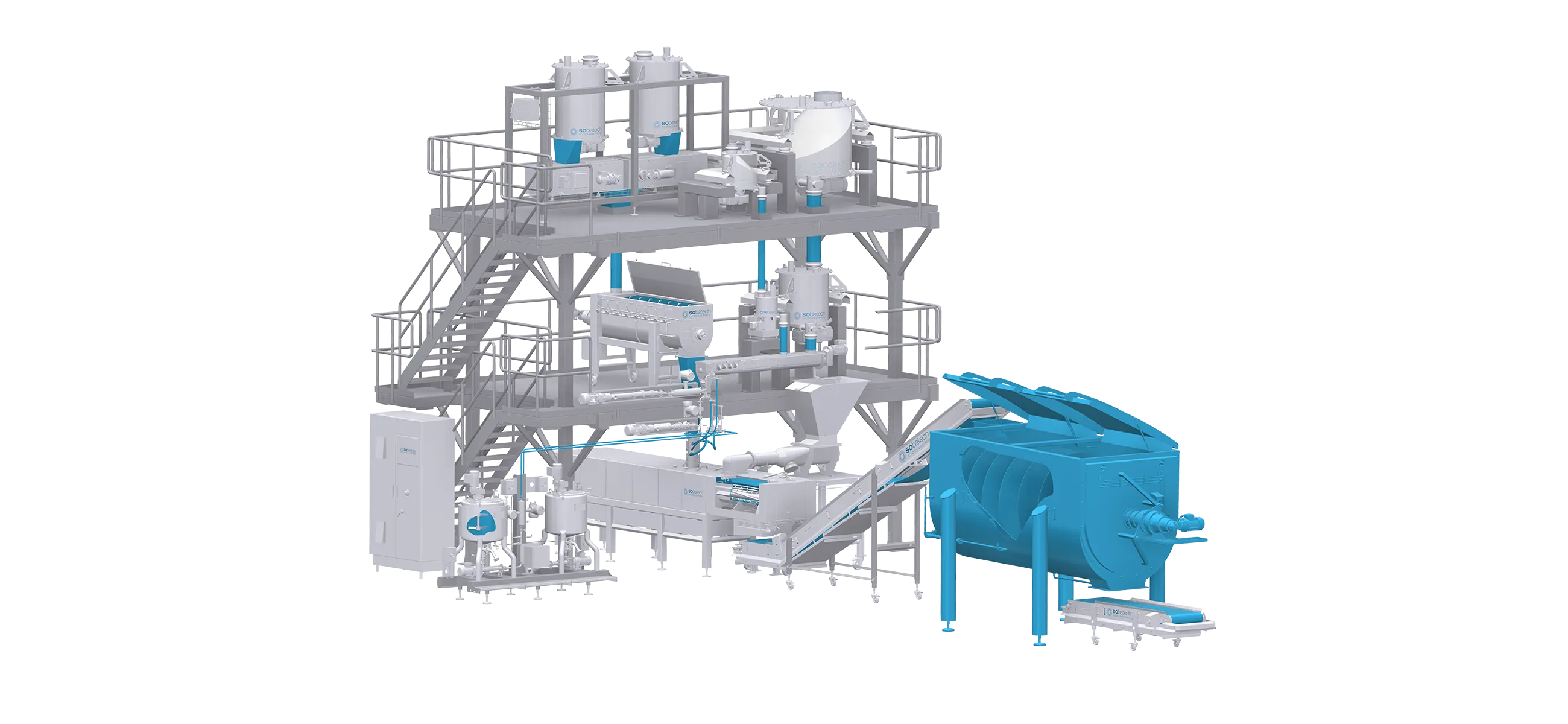

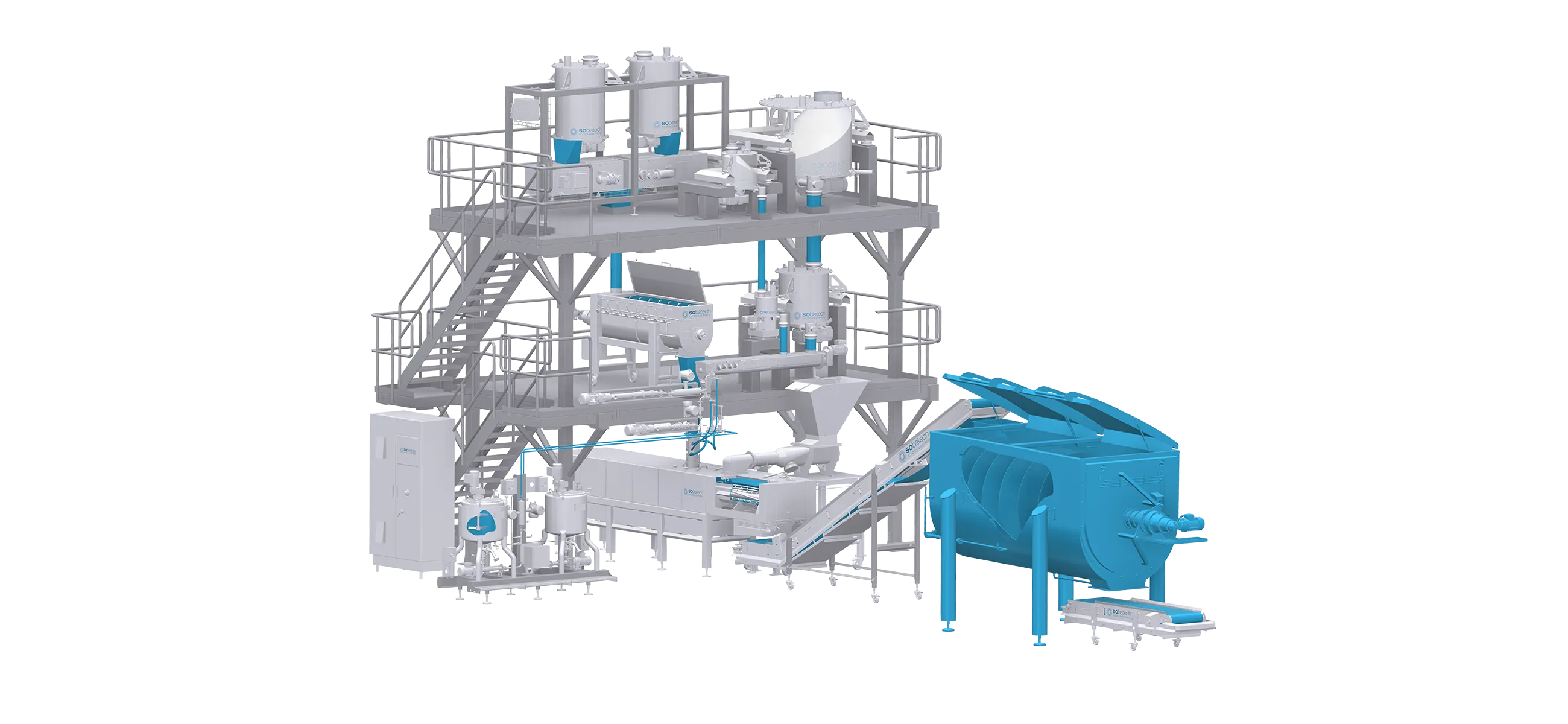

Enhance your plant-based meat production with Sobatech’s continuous (TVP) hydrater, designed to evenly hydrate texturized vegetable proteins (TVP) without compromising their structure. Ideal for creating high-quality plant-based meat.

Sobatech's gravimetric dosing hoppers offers advanced and accurate dosing hardware and software. Discover unparalleled control over the powder dosing process.

.webp)

Sobatech’s continuous bulk fermenters are designed to optimize product quality with precise control over time, humidity, and temperature. Discover how the continuous bulk fermenter is setting the stage for superior end-products results.

.webp)

Cleaning in Place (CIP) is an automated system designed to efficiently clean Sobatech continuous dough mixer. The process ensures thorough cleaning with minimal manual intervention in 15 minutes.

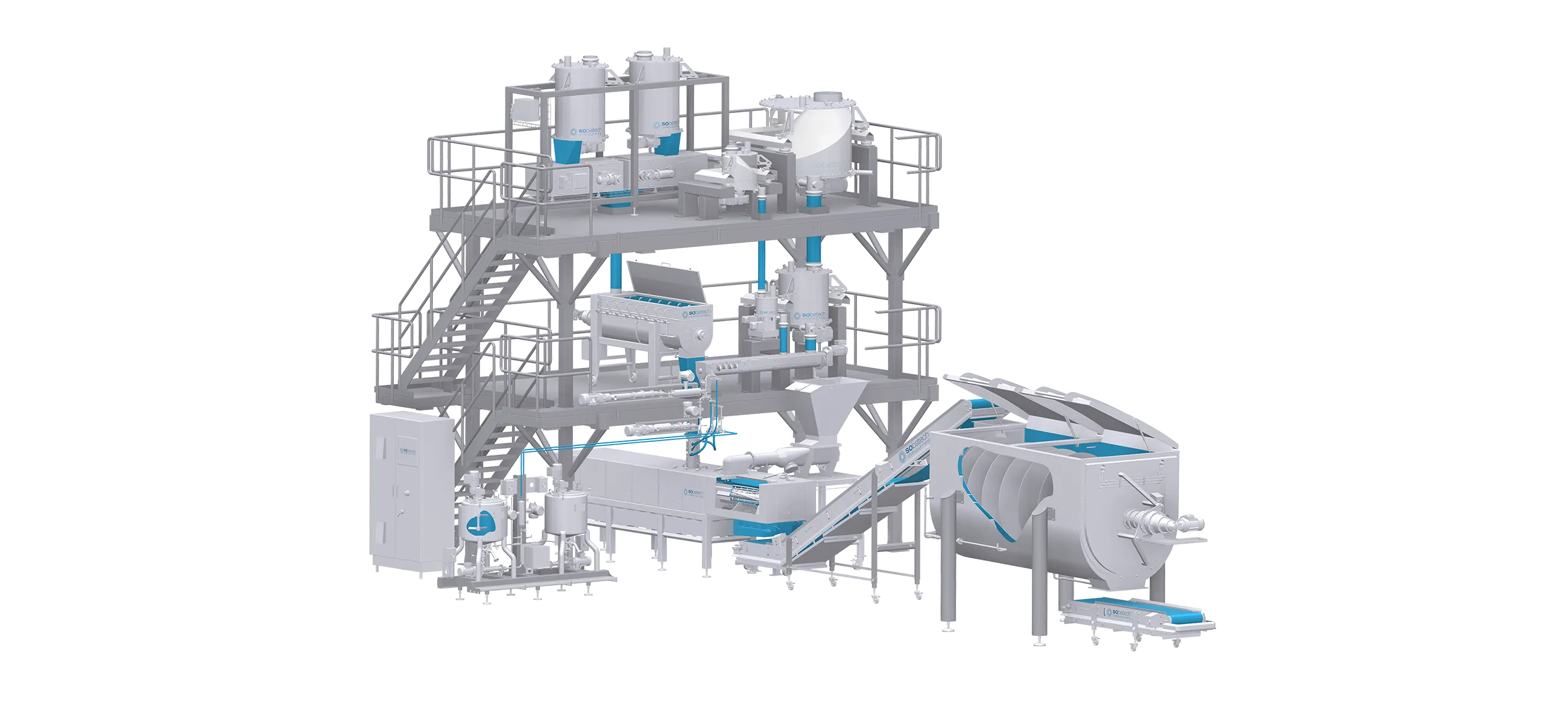

Our experts are ready to help you optimize your production process.

Reach out today to discover how our continuous mixing systems can enhance your production process.

Discover the future of manufacturing at Sobatech's demonstration center. See our innovative continuous mixing systems in action and experience how they can optimize your production line. Whether you want to improve product quality, boost automation, or increase efficiency, experience at our democenter how Sobatech can elevate your production to new heights.

.webp)

.webp)