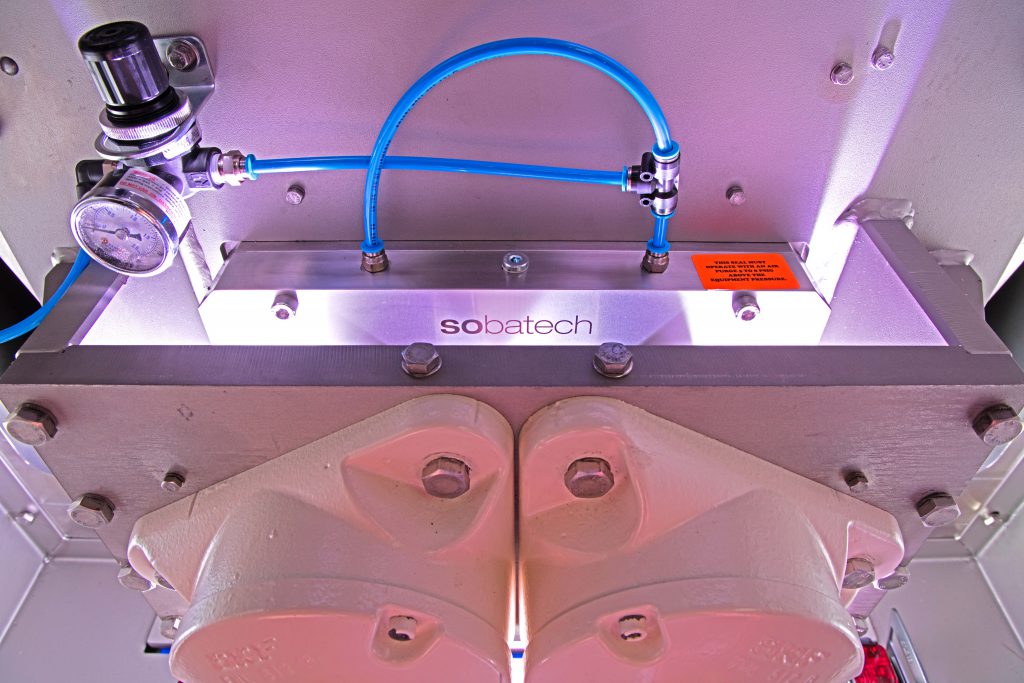

The Sobatech team is excited to showcase the latest continuous dosing and mixing project doing 1.500 kg of breadcrumb dough per hour. The system doses four liquid- and two solid ingredients via the Sobatech homogenizer (phase 1 mixing) in the continuous mixing chamber (phase 2 mixing). The mixing tools generate the exact kneading intensity determined during trials executed prior to the launch of this project.

liquid ingredients

All liquid ingredients are stored in a seperate storage tank of about 150 liter. After that, they are being positively displaced to the homogenizer phase (phase 1 mixing). The liquid ingredients flow through a tube that is supplied with energy by a fixed vibration. When a liquid passes through this tube, the mass flow momentum will cause a change in the tube vibration. This mass flow measuring principle is called Coriolis and has the advantage that there is no need to compensate for changing temperature, viscosity and pressure conditions of the liquid.

solid ingredients

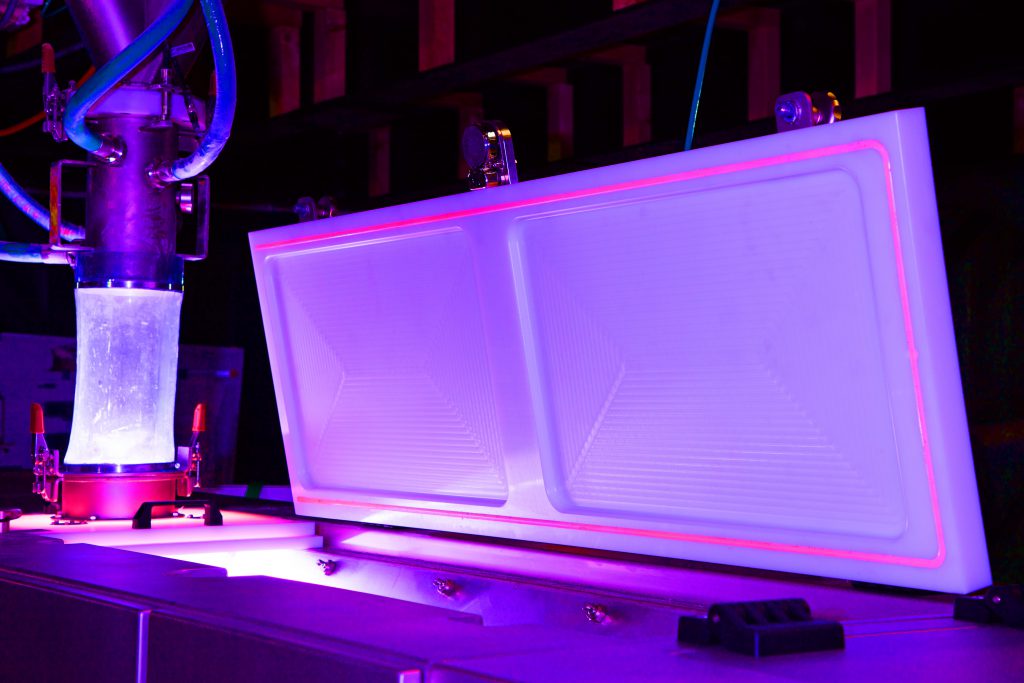

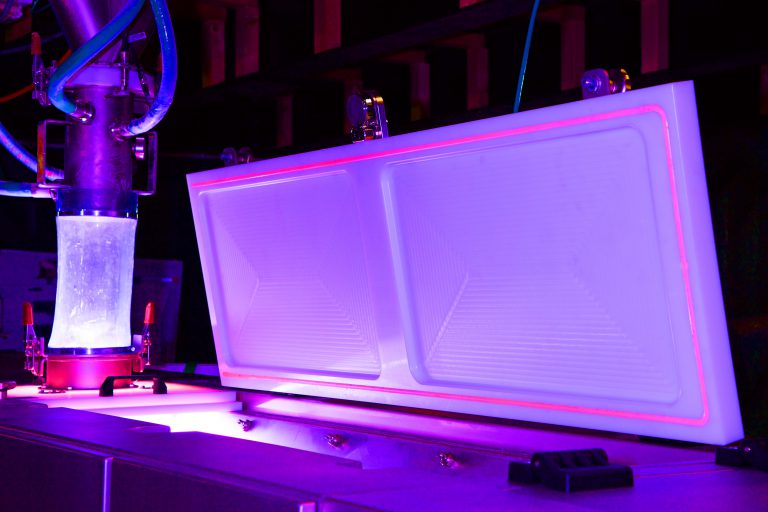

Both solid ingredients (flour and premix) are dosed via a gravimetric weighing belt measuring the weight reduction per time unit. The solid ingredients meet the liquid ingredients inside the homogenizer (phase 1 mixing). In this phase the solid ingredients are being injected by the liquids (in a pre-defined order) via medium pressure.

continuous mixing

The homogenizer can be described as a non-mechanical way of blending the liquid and solid ingredients before they enter the actual mixing chamber. The mixing chamber and corresponding mixing tools create the desired mechanical shear force. Please see below for a variety of pictures showing Sobatech’s continuous dosing and mixing design.

Proud regards,

-Team Sobatech