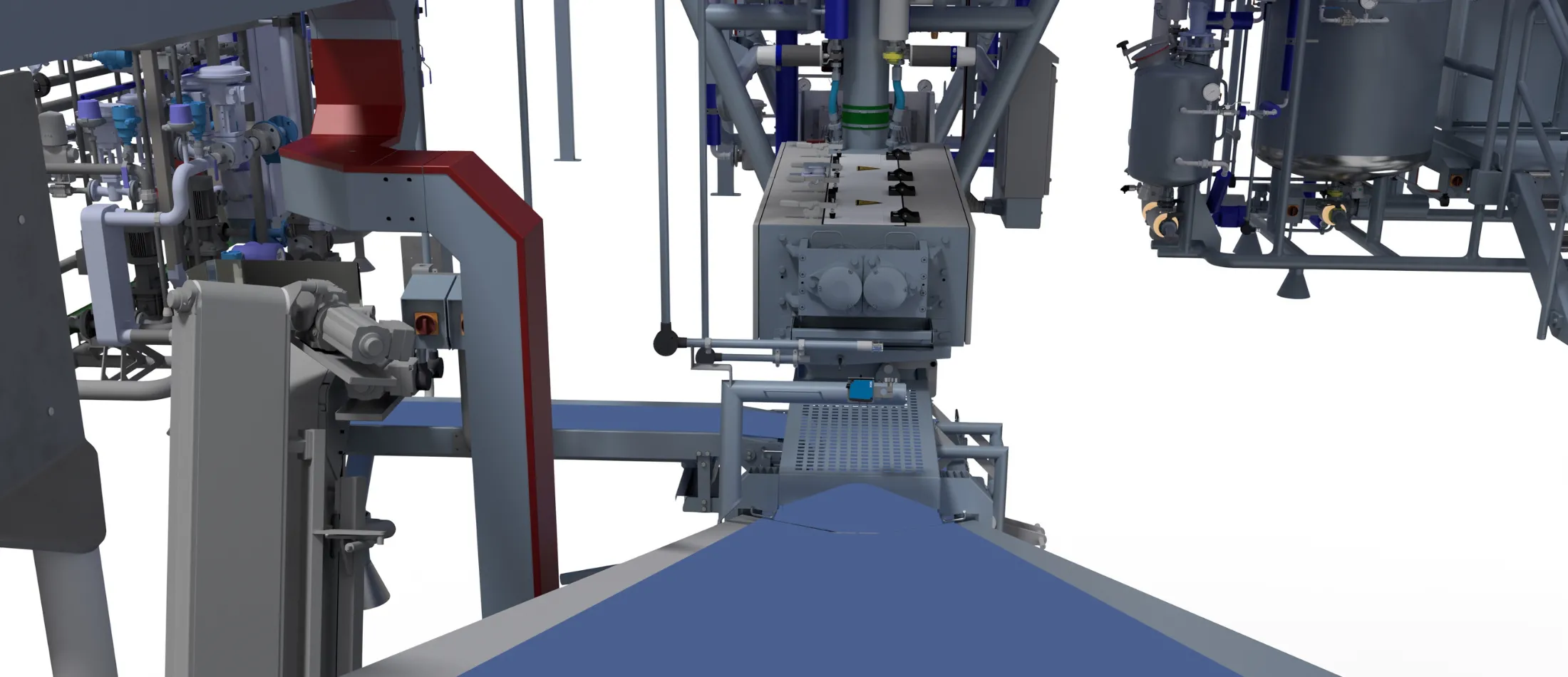

Continuous mixing for breadcrumbs

In industrial breadcrumb production, crumb quality is determined by precise hydration, stable dough structure, and controlled processing. Variations in dough moisture or density can lead to uneven baking, irregular drying, and inconsistent crumb size. Traditional batch mixing methods are often operator-dependent, inefficient, and difficult to scale. Sobatech provides fully continuous and automated dosing and mixing solutions. These technologies ensure a stable dough base every second of production, delivering higher consistency, improved efficiency, and a reliable crumb structure for industrial-scale manufacturing.