Controlled kneading intensity in continuous dough mixing

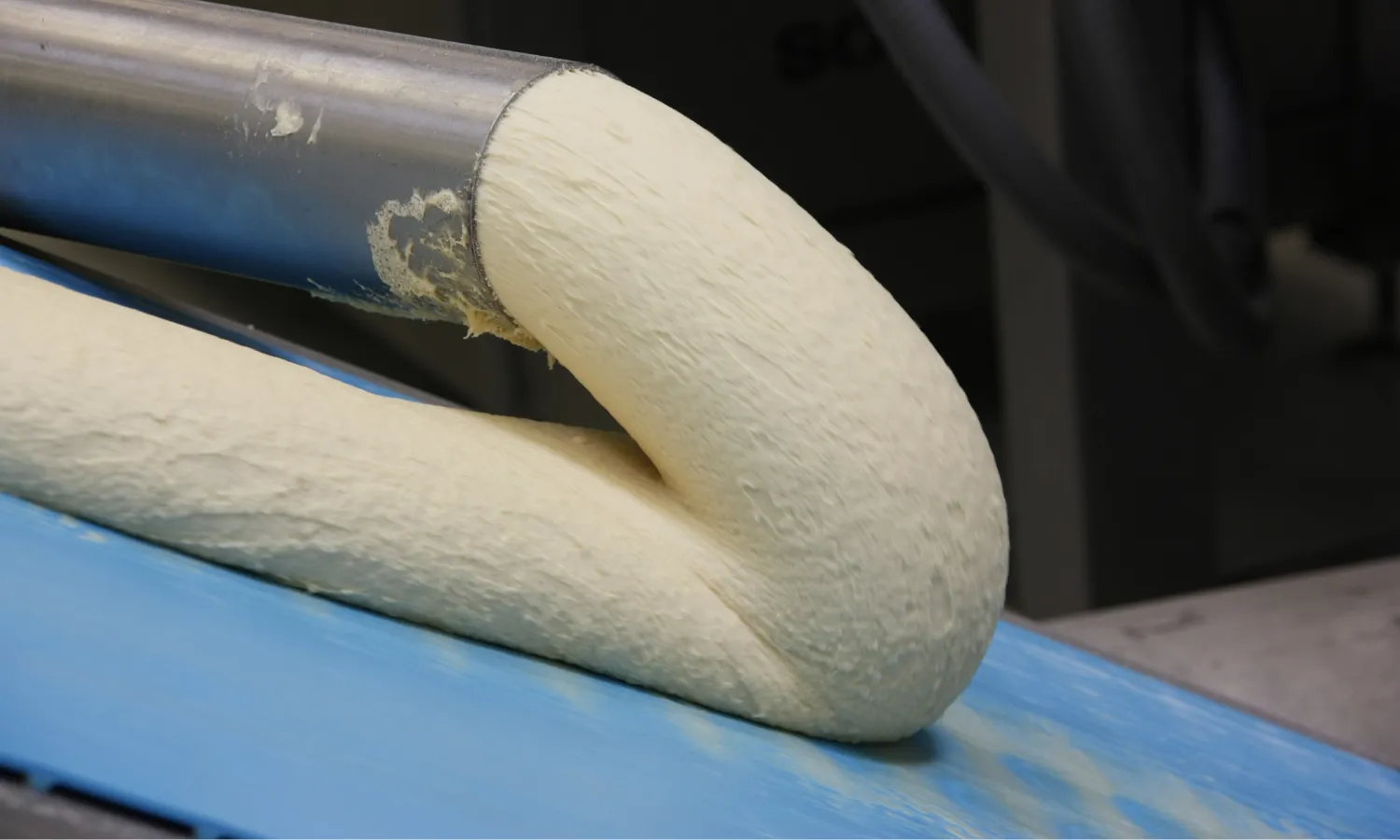

In dough production, gluten network development is strongly influenced by the mechanical energy transferred during mixing. At Sobatech, this energy input is quantified in watt-hours per kilogram (Wh/kg), providing an objective and reproducible parameter linked to dough structure, extensibility, and final product performance.

Sobatech’s continuous mixing systems monitor and control energy input (Wh/kg) in real time, enabling precise regulation of kneading intensity and consistent dough development. By controlling energy input rather than relying solely on time or mixer speed, process variability is reduced and mixing becomes more predictable at industrial scale. This results in greater process transparency, improved efficiency, and a reduced risk of over- or under-mixing.

Different dough types require varying levels of energy input to achieve optimal texture and elasticity. Examples include:

By precisely controlling the energy input, Sobatech ensures that each dough type receives the exact kneading intensity it requires for ideal development.

The mixing tools inside Sobatech’s continuous mixers are meticulously engineered to deliver the required energy input for each specific dough type. Tool design plays a critical role in achieving the desired kneading intensity and ensuring repeatable, high-quality results.

Sobatech has identified over 35 design variables that influence dough quality. These factors are integrated into a proprietary mathematical model used to tailor each mixer. The required energy input (Wh/kg) is a foundational parameter in this design process, ensuring the mixer is optimized for the product it will produce.

Controlling kneading intensity through measured energy input provides a number of critical benefits:

By using Wh/kg as a key control parameter, Sobatech ensures that dough is neither under-developed nor overworked—delivering consistent quality and performance in industrial bakery applications.

Sobatech’s continuous mixing systems offer unmatched control, precision, and flexibility by using energy input as a measurable parameter. Whether you produce soft cookies, crisp baguettes, or high-volume toast bread, Sobatech can design a system optimized for your exact product needs.

Want to know what this means for your production line? Contact us.

.webp)

.webp)

.webp)