Batch mixing vs. continuous mixing

.webp)

.webp)

As food production has scaled globally, so have the demands on industrial dough mixing systems. While batch mixers once met the needs of early commercial bakeries, the rise in demand for consistent, high-volume dough production has paved the way for continuous mixing technology.

In this article, we explore the key differences between batch and continuous mixing, and why more bakeries are switching to continuous systems for greater efficiency, automation, and consistent product quality.

When industrial bakeries first emerged, batch mixing was the standard. It offered enough flexibility and output to meet demand at the time. However, with rising global food consumption, larger-scale production facilities required more efficient, automated, and scalable mixing solutions.

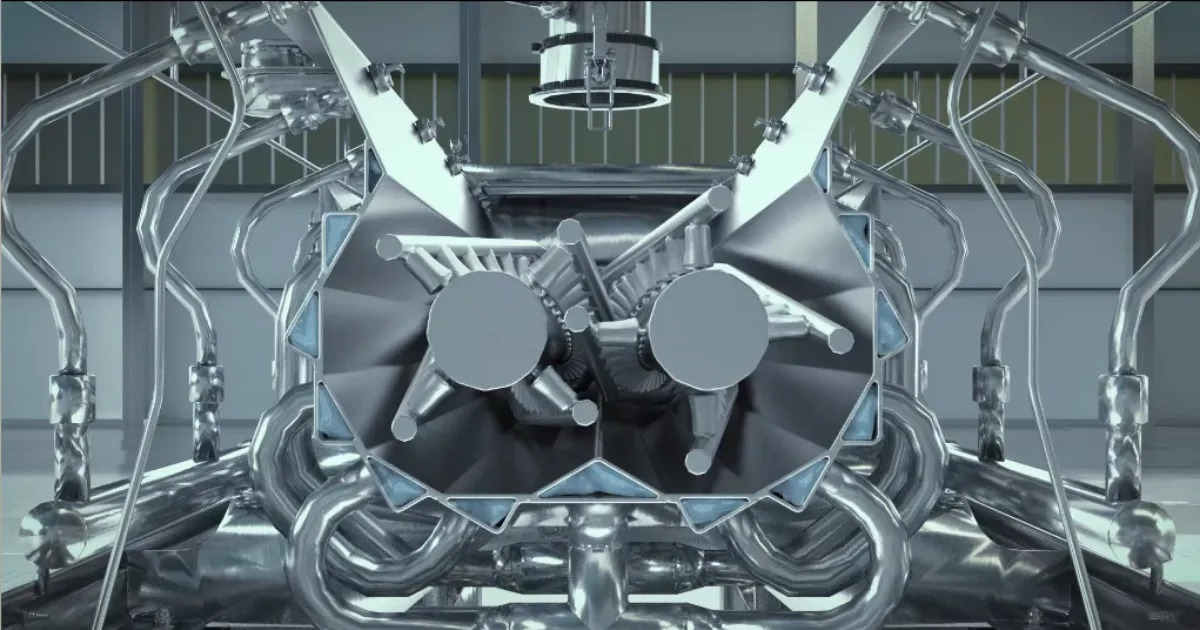

Modern continuous mixing systems can produce up to 12,000 kg of dough per hour with minimal manpower, accurate recipe control, and consistent product quality, all within a single integrated system.

The answer is that until around 20 years ago, the ingredient handling and weighing technologies were not advanced enough to feed the mixer at rates high enough to meet the demand of the continuous mixing process. The past two decades, this technology has advanced immensely enabling an extremely accurate dosing of seperate ingredients into the continuous mixing system.

With these advancements, many bakeries are now asking: “Should we switch from batch to continuous mixing?”

There are still misconceptions about the cost comparison between batch and continuous mixing systems. Often, the cost of a complete continuous mixing system (including ingredient weighing and dosing) is mistakenly compared to the cost of a standalone batch mixer without dosing equipment.

In continuous systems, ingredients are dosed directly into the mixer, which increases automation and accuracy. While the initial investment may be higher, the long-term benefits, such as improved consistency, reduced labor, and lower operational costs, often result in a significantly lower total cost of ownership over time.

While continuous mixing of dough is readily credited with operational and cost advantages, many food producers also select continuous mixing based on the promise of increased product consistency and quality.

Creating dough in discrete batches will always introduce slight variations from batch to batch. While these seem manageable they will always lead to inconsistency over time. Trying to manage quality while chasing these variables will add to the already higher and ongoing labor cost of batch mixing. On top of the inherent variation introduced by the mixing process itself, batch mixing implies that the batch of dough will spend some amount of time waiting to be processed after being mixed.

Dough is a living entity where chemical and physical changes take place from the time water is added to the dry ingredient until the product is finished baking. The dough will change over that period of time due to aging, environmental conditions and the interactions of the seperate ingredients.

These batch-to-batch dough variations result in varying piece weights which create inconsistencies during packaging. On a continuous mixing process there is a continuous stream of dough meaning every piece of dough has had the same fermentation process and age. This constant consistency is one of the largest benefits to continuous dough mixing and strongly contributes to the growing popularity.

In case of batch mixing, the weighing of the ingredients can be done manually; saving significant costs on the short term. In case of continuous mixing, the dosing of raw materials is done automatically at the mixer and requires greater automation and accuracy. As a result, the product quality is independent of the skills of the operators. Even though, the initial investment of the automated ingredient weighing might be higher on a continuous mixing system; on the long term the improved weighing technology will represent significant cost savings.

Batches of dough typically come in an unpractical form, meaning that additional equipment is required to resize the batches. This additional process step creates unnecessary shear and exposure of the dough. A continuous mixer creates continuous streams of dough that can be cut in-line. Generally on a continuous mixing process, there is no need for additional equipment to resize the batches.

At Sobatech, we understand that transitioning to a new mixing method is a significant step. To support food producers in this process, we offer access to our dedicated testing facility.

Here, food manufacturers can test their own recipes and ingredients on a continuous mixing system, helping to evaluate performance, consistency, and output before making an investment decision.

Both batch and continuous mixing systems have their place in food production, but the benefits of continuous mixing (automation, efficiency, and product consistency) make it a compelling choice for modern bakeries aiming to scale and optimize operations.

If you are evaluating your dough production setup, now is the ideal time to explore how continuous mixing technology can streamline your process and improve your end product.

Contact Sobatech to visit our testing facility to experience the future of industrial dough mixing firsthand.

.webp)

.webp)