Loss-in-weight feeder challenges

.webp)

.webp)

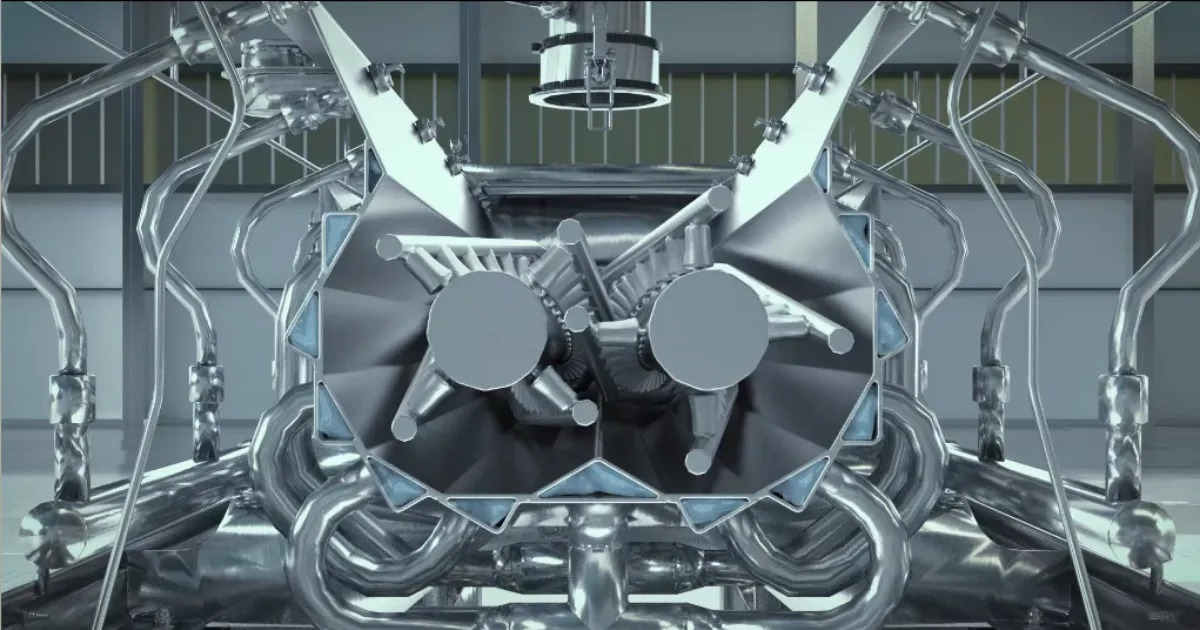

Sobatech utilizes gravimetric feeding systems to introduce ingredients into its continuous mixing processes. A gravimetric feeder delivers a precise weight of material per unit of time. In such systems, the motor automatically adjusts its speed in response to changes in material flow, eliminating the need for manual intervention, which is often necessary when using volumetric feeders. These changes in flow can result from factors such as the addition of new material or fluctuations in material density.

In continuous production environments, dosing accuracy is critical—every fraction of a second counts. For this reason, gravimetric feeding systems are preferred, as they offer superior precision and consistency. Sobatech employs loss-in-weight feeders, which are gravimetric systems that measure weight reduction over time to determine the feed rate.

There are three primary challenges to consider with loss-in-weight dosing systems:

A loss-in-weight feeder must remain isolated from external forces while it receives and discharges material, to maintain weighing accuracy. Advanced digital filtering can help disregard brief disturbances; however, sustained external influences can degrade the feeder’s performance over time.

Because these systems often require extremely high dosing precision, even minor fluctuations in total system weight must be accurately detected. Therefore, load cells must be both highly sensitive and stable, and insulated from environmental disturbances such as shocks or vibrations, which could compromise the measurement and therefore the feed rate.

Best practices to mitigate these effects include:

When the hopper is refilled, the system weight increases, rendering weight-based feed rate control temporarily ineffective. There are two methods for addressing this issue:

Conventional method

This approach maintains a constant motor speed throughout the refill phase. Once the system detects a weight increase, it holds the screw speed at the value measured just before refilling began. During this time, the feeder effectively operates in a volumetric mode. After refilling and material settlement, the system resumes gravimetric control.

However, for compressible materials, this can result in overfeeding. The added weight during refill compresses the material, increasing its density. If the feeder maintains the higher pre-refill speed, the system may temporarily overdose the material, resulting in a sudden adjustment and a temporary period of inaccurate dosing.

Advanced (alternative) method

A more precise approach involves storing recent weight-to-speed data from gravimetric operation and using it to guide motor speed during the volumetric refill phase. This method accounts for material compressibility and eliminates inaccuracies due to density changes. Essentially, the system "remembers" how the hopper fill level corresponds to screw speed and adjusts accordingly, maintaining more consistent feed rates even during refilling.

Material flow disruptions, such as arching or ratholing, can prevent proper discharge. As the feeder attempts to dispense material blocked above the outlet, the actual feed rate drops to zero. The system may increase screw speed in response, but if material is not flowing, the weight remains static, and the feeder may reach its speed limit or trigger alarms due to performance deviations.

These issues may result from changes in ingredient suppliers, storage conditions, temperature variations, or transport practices. The two main types of flow disruptions are:

Standard measures include:

However, Sobatech believes in preventing problems rather than solving them afterward. That is why the aforementioned challenges have been proactively addressed in the design of the Sobatech Flat Bottom Dosing Hopper.

The result is a loss-in-weight feeder that delivers exceptional accuracy during both loss-in-weight and gain-in-weight operation, is highly resistant to external vibrations, and effectively prevents issues such as ratholing and bridging.

For more information about Sobatech’s Flat Bottom Dosing Hopper, please visit: Sobatech dosing hoppers

.webp)