Sobatech continuous mixer designs

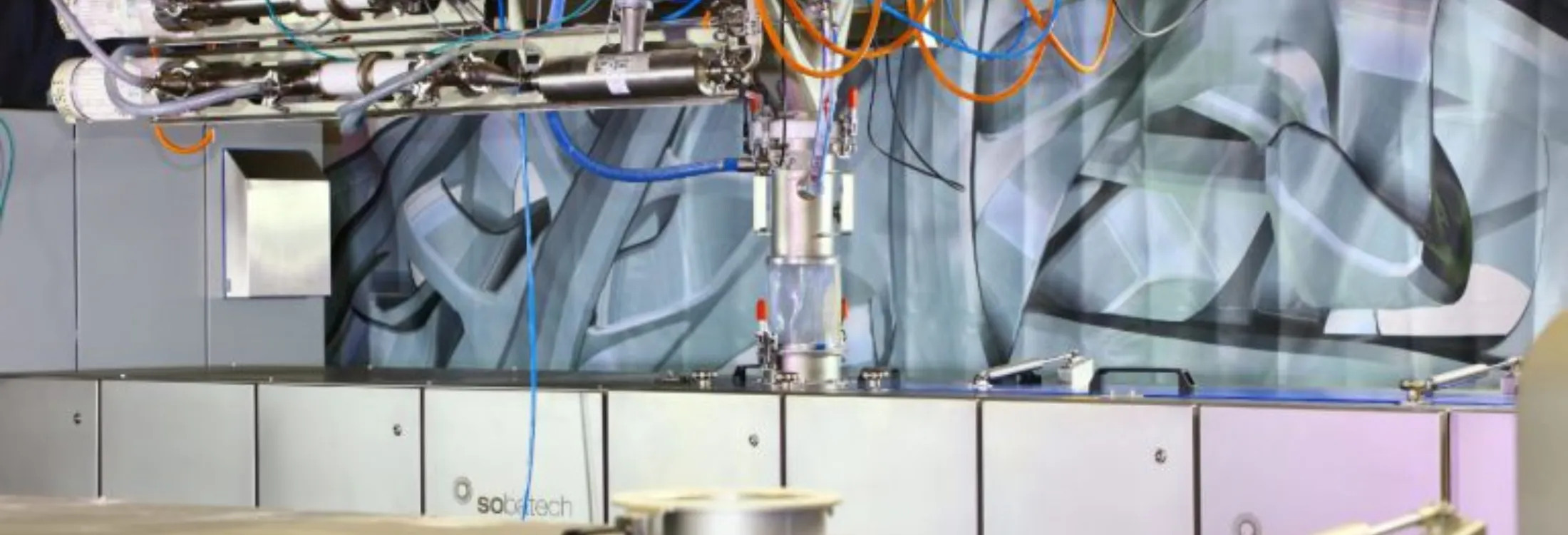

At Sobatech, mixer design has been at the heart of our continuous mixing systems. Since the founding of the company in 2006 by Gilian Lekner, we have focused on developing innovative and hygienic continuous mixers tailored to the food and non-food industry. Today, nearly 15 years later, mixer design and engineering excellence remain a core part of Sobatech’s DNA.

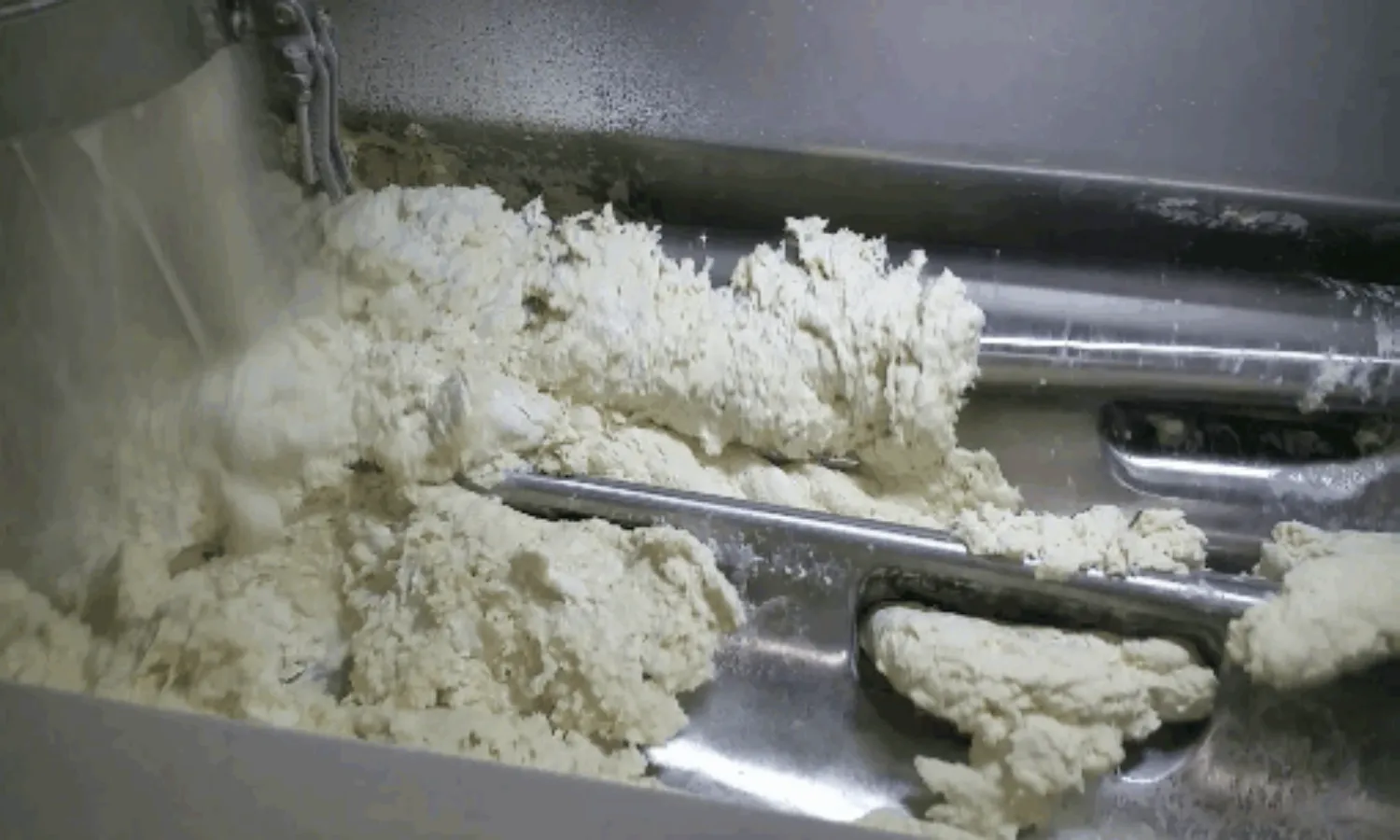

Sobatech’s continuous mixers are instantly recognizable—a design signature we proudly maintain. More importantly, they are engineered to meet the stringent hygiene and safety requirements of modern food and non-food production. Every mixer features a high level of hygienic construction as standard, playing a critical role in maintaining microbiological safety and product quality. These systems can also be customized to meet specific mixing and hygienic requirements.

Sobatech’s first generation, known as the X-design, featured a recognizable look but left room for improvement in terms of hygiene. This early version laid the foundation for our future innovations.

In 2015, Sobatech introduced the hanging continuous mixer design, a game-changing innovation for hygienic production environments. This mixer can be suspended from a factory platform or ceiling structure, eliminating floor contact entirely. The hanging design simplifies floor cleaning procedures and enhances overall sanitation.

All Sobatech mixers are engineered with rounded and sloped surfaces for optimal drainage. Each component is precisely welded, flushed, and polished to create an ultra-smooth surface that resists buildup and contamination. These features support both easy cleaning and long-term durability.

Today, Sobatech offers three hygienic design options:

Each design offers specific advantages depending on your factory layout and sanitation goals. Whether you are working with limited floor space or aiming for maximum cleanability, Sobatech provides a continuous mixer solution to match your requirements.

%20(1).webp)

.webp)